In the urban waste treatment and resource utilization system, screening is a crucial prerequisite, and its efficiency and accuracy directly determine the effectiveness of the subsequent treatment process. As an efficient screening device, the garbage drum screen has become a core equipment in solid waste treatment scenarios such as household waste and construction waste, thanks to its unique structural design and excellent working performance. This article will deeply analyze the technical characteristics of garbage drum screens from three dimensions: structural composition, core features, and application advantages, providing theoretical support for their promotion and application.

A. The structural composition and core characteristics of garbage drum screen

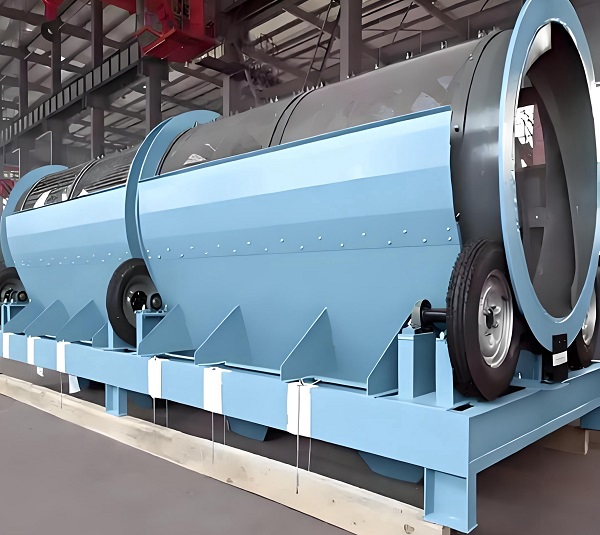

The structural design of the garbage drum screen revolves around three core goals: stable operation, efficient screening, and adaptability to complex materials. It mainly consists of six core components: drum body, support device, drive system, feeding device, discharging device, and cleaning system. Each component works together to form a complete screening system.

1. Drum body: the core carrier of screening function

The drum body is a key component for the garbage drum screen to achieve screening function, and its structural design directly determines the screening efficiency and adaptability. The drum body usually adopts a cylindrical structure, welded from high-strength steel plates, with special guide plates and cutting plates on the inner wall. The guide plate is distributed in a spiral shape, which can guide the material to move uniformly along the axis of the drum, avoiding material accumulation inside the drum; The copying board is perpendicular to the inner wall of the drum. During the rotation of the drum, the material can be lifted to a certain height and scattered, allowing the material to fully contact the sieve and improve the screening accuracy.

As the core component of the drum body, the screen adopts a modular design. According to the particle size requirements for garbage treatment, different aperture screens can be selected, such as 5mm, 10mm, 20mm, etc., and they are easy to replace, reducing equipment maintenance costs. In response to the problem of high impurities and easy wear of the screen mesh in garbage, the screen mesh material is usually selected as high manganese steel or stainless steel, which has high strength, high wear resistance, and corrosion resistance, effectively extending the service life of the screen mesh. In addition, some drum bodies adopt a tilted design, and the tilt angle can be adjusted between 3 ° -8 °, assisting material flow through gravity and further improving screening efficiency.

2. Supporting device: the fundamental guarantee for stable operation

The supporting device is mainly composed of supporting wheels, blocking wheels, and brackets, which bear the entire weight of the drum body and ensure its stable operation during high-speed rotation. The supporting wheel is made of high-quality cast steel material and has undergone quenching treatment on the surface, with high hardness and strong wear resistance. The curved surface in contact with the drum body is precision machined to ensure uniform contact area and reduce local wear. The blocking wheels are installed at both ends of the drum body to limit the axial displacement of the drum body, prevent deviation during operation, and ensure the stability of equipment operation.

The bracket is made of welded steel structure and optimized through finite element analysis design. It has sufficient rigidity and strength to effectively absorb the vibration generated during equipment operation and reduce the impact on the foundation. At the same time, there is a leveling device at the bottom of the bracket, which can be adjusted according to the actual situation of the installation site to ensure that the equipment is in a horizontal state and provide basic conditions for the stable operation of the equipment.

3. Drive system: the power source for efficient operation

The drive system adopts a combination of "motor+reducer+chain/gear transmission" to provide stable power for the rotation of the drum body. The motor is selected as an efficient and energy-saving three-phase asynchronous motor, which has the characteristics of high power factor, low energy consumption, and stable operation. The output speed can be adjusted according to the screening requirements. The reducer adopts a hard toothed cylindrical gear reducer, which has high transmission efficiency, low noise, and strong load-bearing capacity. It can convert the high-speed rotation of the motor into the low-speed rotation required by the drum body, ensuring a smooth and orderly screening process.

In terms of transmission mode, chain transmission has the advantages of simple structure, easy maintenance, and low cost, and is suitable for small and medium-sized garbage drum screens; Gear transmission has the characteristics of high transmission accuracy, good stability, and long service life, and is suitable for large or high-intensity operation of garbage drum screens. Some high-end equipment is also equipped with a variable frequency speed control system, which can adjust the speed of the drum body in real time according to the properties of the material and screening requirements, further improving the adaptability and screening efficiency of the equipment.

4. Feeding and discharging devices: smooth channels for material flow

The feeding device adopts a funnel-shaped structure with a dust cover at the top, which can effectively prevent the spread of dust generated during the material feeding process and improve the working environment. The funnel is equipped with a guide plate inside, which can guide the material evenly into the drum body, avoid the concentrated impact of the material on the screen, and reduce local wear. At the same time, the size of the feeding port can be adjusted according to the feeding amount of the material to ensure that the material supply matches the screening efficiency.

The discharge device adopts a multi-channel design based on the difference in particle size of the screened materials, collecting materials of different particle sizes separately, such as oversized materials on the screen, medium sized materials in the screen, and small materials under the screen, for subsequent classification and resource utilization. There is usually a conveyor belt interface below the discharge port, which can be directly connected to subsequent processing equipment to achieve continuous material flow, reduce manual handling costs, and improve the automation level of the entire processing line.

5. Cleaning system: an important auxiliary to ensure screening efficiency

The composition of garbage is complex, containing a large amount of viscous substances that are prone to adhere to the surface of the sieve, causing the sieve to clog and reducing screening efficiency. For this purpose, the garbage drum screen is specially equipped with a cleaning system, mainly including a high-pressure spray device and a bristle cleaning device. The high-pressure spray device is installed inside or outside the drum body, and water is sprayed on the surface of the screen in an atomized form through a high-pressure water pump, which can effectively wash away the viscous materials attached to the screen; The bristle cleaning device rotates synchronously with the drum body, and the bristles are in close contact with the screen mesh. During the rotation of the drum body, the screen mesh is continuously cleaned to further prevent clogging.

Some cleaning systems also adopt automatic control technology, which can automatically adjust the spray intensity and bristle speed according to the blockage of the screen mesh, ensuring the cleaning effect and avoiding the waste of water resources. The setting of the cleaning system effectively extends the cleaning cycle of the sieve, improves the continuous operation time of the equipment, and reduces manual maintenance costs.

B. The application advantages of garbage drum screen

Compared with traditional screening equipment such as vibrating screens and fixed screens, the unique structural design of garbage drum screens gives them many advantages such as high screening efficiency, strong adaptability, and stable operation, which have been widely used in the field of garbage treatment.

1. High screening efficiency and strong processing capacity

During the rotation of the drum body of the garbage drum screen, the material can achieve sufficient contact with the screen mesh and multiple screenings through the action of the guide plate and the copying plate, effectively improving the material's screening rate. At the same time, the combination of inclined drum design and spiral guide plate ensures uniform and controllable movement speed of materials inside the drum, avoiding material retention in the equipment and ensuring the continuity of the screening process. Compared with vibrating screens, the processing capacity of garbage drum screens has increased by 30% -50%. A single device can process 50-200 tons of garbage per hour, which can meet the large-scale processing needs of large-scale garbage treatment plants.

In addition, the application of variable frequency speed regulation system enables the equipment to adjust the speed in real time according to the feeding amount and properties of the material. When the feeding amount is large, the speed can be appropriately increased to accelerate the material flow speed; When there are many viscous substances in the material, the speed can be reduced, the screening time can be extended, and the screening accuracy can be ensured. This flexible adjustment method further enhances the screening efficiency and processing capacity of the equipment.

2. Strong adaptability and wide applicability

The composition of urban waste is complex, including various materials such as kitchen waste, plastic, paper, metal, construction waste, etc., with significant differences in physical properties, which puts high demands on the adaptability of screening equipment. The garbage drum screen can adapt to the screening needs of different types of garbage materials through modular screen design and reasonable structural layout. For kitchen waste with high moisture content, the cleaning system can effectively prevent screen clogging; For construction waste with high hardness, high-strength screens and support devices can withstand the impact and wear of materials; For larger materials such as plastic and paper, the spiral guide plate can guide them to move smoothly and avoid jamming.

In addition to urban household waste, garbage drum screens can also be widely used in various fields such as construction waste resource utilization, industrial solid waste treatment, and mining tailings screening. In the treatment of construction waste, it can screen concrete blocks, bricks and other materials into recycled aggregates of different particle sizes, which are used to produce recycled bricks, recycled concrete and other products; In industrial solid waste treatment, materials such as fly ash and coal gangue can be classified to provide a foundation for subsequent resource utilization.

3. Stable and reliable operation with low maintenance costs

The structural design of the garbage drum screen is simple and reasonable, with fewer moving parts, mainly the rotation of the drum body, reducing the probability of equipment failure. The supporting and blocking wheels in the supporting device have undergone precision machining and heat treatment, with strong wear resistance and a service life of up to 5-8 years; The motors and reducers in the drive system are selected from well-known brands, with stable performance and low failure rates. Compared with the vibrating screen, the downtime of the garbage drum screen has been reduced by more than 60%, and the continuous operation time of the equipment can reach 24 hours without interruption.

In terms of maintenance, the modular screen design makes screen replacement more convenient, and a single person can complete screen replacement within 30 minutes; The automatic cleaning function of the cleaning system reduces the workload of manual cleaning of the screen mesh and lowers the labor intensity of maintenance personnel. In addition, the lubrication system of the equipment adopts a centralized lubrication method, which can achieve automatic timed lubrication and reduce the workload of lubrication maintenance. Overall, the annual maintenance cost of the garbage drum screen is only 40% -60% of that of the vibrating screen, significantly reducing the operating cost of the equipment.

4. Energy conservation and environmental protection, in line with the concept of green development

In terms of energy conservation and environmental protection, the garbage drum screen has obvious advantages. The drive system uses high-efficiency and energy-saving motors, which reduce energy consumption by 15% -20% compared to traditional motors; Meanwhile, a reasonable transmission design reduces energy loss, and the transmission efficiency of the equipment can reach over 95%. In terms of dust control, both the feeding and discharging devices are equipped with dust covers, combined with the spray dust reduction function of the cleaning system, which can effectively control the dust pollution generated during the screening process. The dust emission concentration is lower than the national emission standard (10mg/m ³).

In addition, the efficient screening function of the garbage drum screen provides strong support for the resource utilization of garbage. Through precise classification of garbage, the recovery rate of recyclable materials can be improved, the amount of garbage buried and incinerated can be reduced, and the pollution to the environment during garbage disposal can be reduced. For example, in the treatment of household waste, the small materials screened by the drum screen can be used for biological composting, the medium particle size materials in the screen can be used for incineration power generation, and the large materials on the screen can be crushed and reprocessed, achieving the reduction, harmlessness, and resource utilization of waste, which is in line with the concept of green development in China.

The garbage drum screen, with its reasonable structural design and excellent application advantages, has become the core equipment in the garbage treatment system. The synergistic effect of core components such as the drum body, support device, and drive system ensures the efficient and stable operation of the equipment; The advantages of high screening efficiency, strong adaptability, low maintenance cost, energy conservation and environmental protection have made it widely used in various fields such as urban household waste, construction waste, industrial solid waste, etc. With the continuous development of garbage disposal technology, garbage drum screens will further develop towards large-scale, intelligent, and efficient directions. By integrating advanced technologies such as the Internet of Things and big data, real-time monitoring and intelligent regulation of equipment operation status will be achieved, providing stronger technical support for the development of China's garbage resource utilization industry.

Save Time! Get A Detailed Quotation Quickly.