As an indispensable key equipment in the material handling process, magnetic separators are widely used in industries such as coal, power, metallurgy, building materials, and chemicals. Their core function is to effectively remove ferromagnetic impurities from materials, preventing equipment wear, jamming, or even damage caused by iron impurities, while ensuring the safety of subsequent production processes and product quality. Correct installation and scientific maintenance are fundamental to ensuring the long-term stable operation and full performance of magnetic separators. This article will detail the key points of magnetic separator installation and maintenance, covering aspects such as pre-installation preparation, installation procedures, installation precautions, daily maintenance, regular inspections, and troubleshooting.

A. Installation of Magnetic Separators

1. Pre-installation Preparation

Thorough preparation before installation is a prerequisite for the smooth progress of the installation work. This needs to be carried out from three core dimensions: equipment inspection, site planning, and tool preparation. First, conduct an inspection of the equipment's appearance and components. Carefully check whether the main body of the magnetic separator, control cabinet, cables, connectors, and other components are complete, and whether there is any deformation, damage, or missing parts caused during transportation. Pay particular attention to the integrity of core components such as the magnetic system and coils. At the same time, verify that the equipment model and technical parameters are consistent with the on-site production requirements and design scheme, ensuring that the equipment meets the installation and use requirements. Secondly, carry out site planning and cleaning. Determine the specific installation location based on the type of magnetic separator (such as suspended, drum, or pipeline type) and the layout of on-site conveying equipment (belt conveyors, pipelines, vibrating screens, etc.). The installation location must meet the following core requirements: First, it should be close to the source of impurities, preferably installed before material crushing and screening, to reduce the wear of subsequent equipment by iron impurities; second, ensure sufficient installation space for subsequent equipment inspection and maintenance. Suspended magnetic separators require sufficient lifting and adjustment space, and drum-type magnetic separators need to be precisely matched with the installation position of the belt conveyor's drum; third, it should be away from strong magnetic fields, high temperatures, humidity, and corrosive environments to avoid affecting the magnetic performance and lifespan of the magnetic separator's electrical components. Finally, prepare the installation tools and auxiliary equipment. Based on the installation requirements, prepare tools such as wrenches, screwdrivers, welding machines, spirit levels, measuring tapes, and cranes (or jacks). Simultaneously, check that all necessary materials for cable laying and grounding devices are available to ensure sufficient tools and materials during the installation process.

2. Core Installation Process

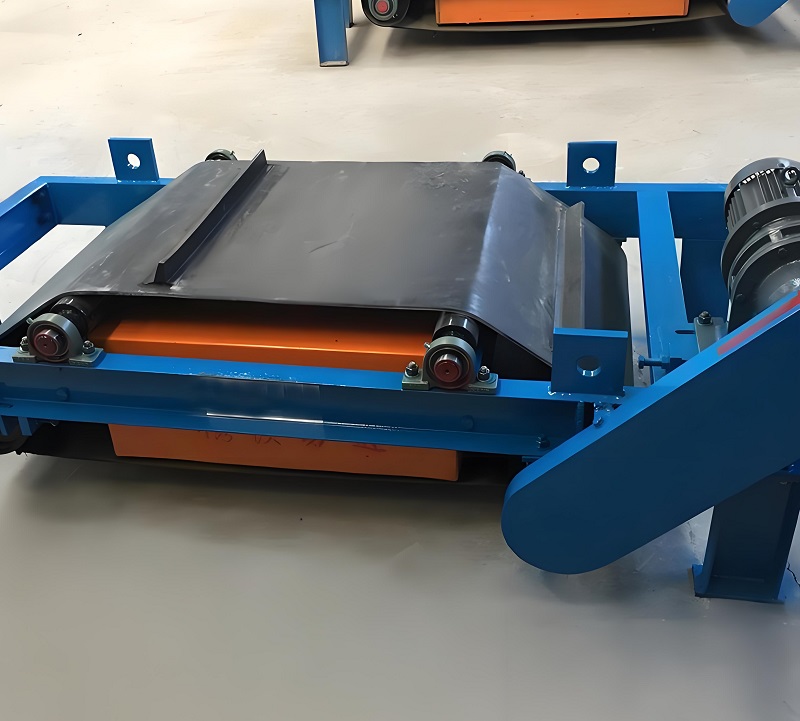

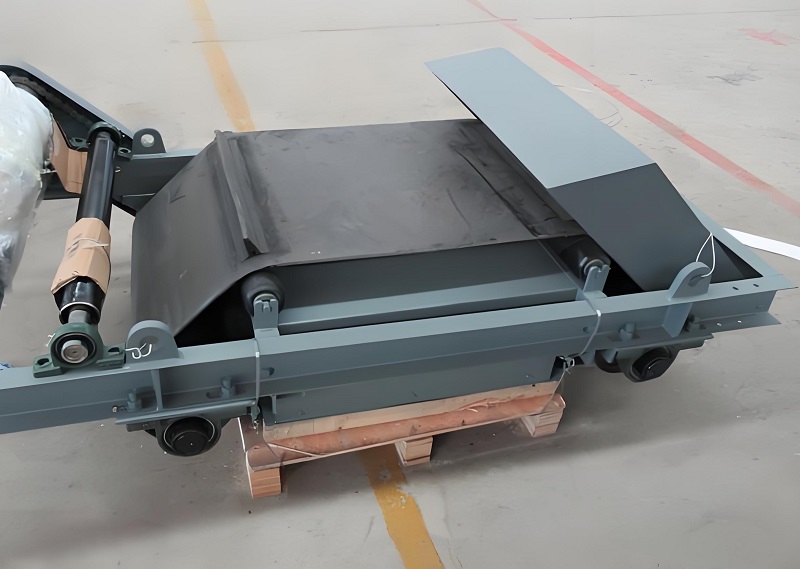

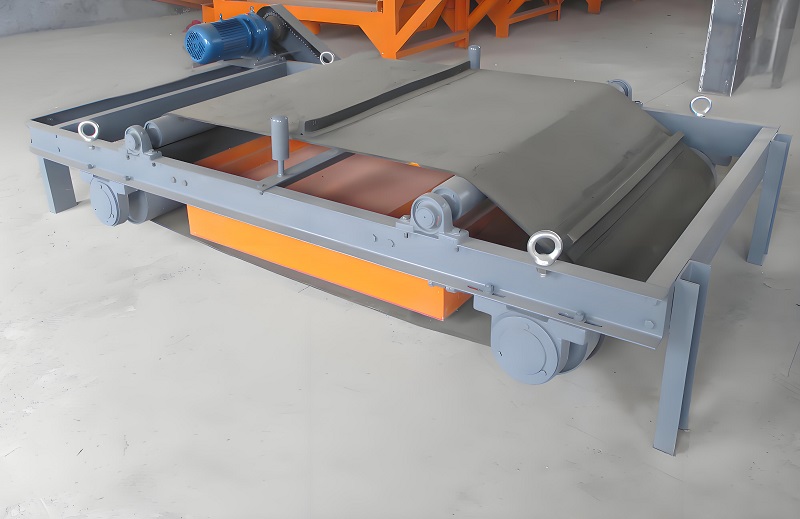

The installation process varies for different types of magnetic separators. The following details the core installation steps using the most widely used suspended magnetic separator (suitable for belt conveyors) and drum-type magnetic separator (integrated into belt conveyors) as examples.

For suspended magnetic separators, the installation process mainly includes bracket installation, equipment suspension, position adjustment, and electrical connection. Bracket installation requires constructing a support structure using welded or bolted steel profiles based on the actual site conditions. The bracket must ensure sufficient strength and stability. Welded joints must be treated for rust prevention, and bolted connections must be tightened securely to prevent loosening due to vibration during operation. During equipment suspension, use a crane to lift the magnetic separator smoothly and slowly place it onto the bracket, securing it with connecting parts. Avoid collisions during suspension to prevent damage to the magnetic system or casing. Position adjustment is a critical step; the centerline of the magnetic separator must coincide with the centerline of the belt conveyor to avoid uneven loading and reduced separation efficiency. Simultaneously, adjust the distance between the magnetic separator and the belt surface based on material thickness, particle size, and belt speed. The distance is usually controlled between 100-300mm; the distance can be appropriately reduced for thicker materials, but contact between the equipment and the belt must be avoided. During electrical connection, strictly follow the electrical wiring diagram, connecting the magnetic separator coil to the control cabinet and power supply, ensuring secure connections and correct phasing. Install the grounding device, ensuring the grounding resistance meets relevant standards (usually not greater than 4Ω) to prevent electrical faults and electric shock risks.

For drum-type magnetic separators, their installation must be synchronized with the replacement of the belt conveyor's drum. The core process includes removing the old drum, positioning the new drum, position calibration, and belt commissioning. First, remove the original rollers of the belt conveyor, clean the installation area of debris and oil stains, and check the integrity of components such as the shaft seat and bearings. If there is wear, replace them promptly. Then, carefully hoist the roller-type magnetic separator to the installation position, adjust the levelness and parallelism of the roller, ensuring that the shaft seats at both ends of the roller are securely installed and that the roller's centerline is parallel to the centerline of the belt conveyor frame. Next, adjust the belt tension to ensure that the belt is tightly fitted to the roller surface, without any deviation, to prevent slipping or belt wear during operation. Finally, connect the roller drive device (if it is a permanent magnet roller, no drive connection is needed) and the electrical control system, and conduct a power-on test run to check whether the roller rotates smoothly and without abnormal noise.

3. Installation Precautions

During installation, the following precautions must be strictly observed to avoid improper installation affecting equipment operation. Firstly, when installing a suspended magnetic separator, sufficient space must be reserved for equipment maintenance.

Typically, a space of at least 50cm should be left around the magnetic separator to facilitate subsequent magnetic system cleaning and component replacement. At the same time, if multiple magnetic separators are installed side-by-side, the distance between adjacent devices must be no less than 1.5m to prevent magnetic field interference. Secondly, violent collisions should be avoided during installation, especially for permanent magnet magnetic separators, as violent impacts may cause magnetic system displacement and demagnetization, affecting the iron removal effect. Thirdly, electrical installation must comply with electrical safety regulations.

Cable laying should use protective conduits to prevent the cables from being squeezed or worn by materials. After wiring is completed, insulation testing should be performed to ensure good insulation performance. Fourthly, for pipeline-type magnetic separators, the flange connection between the equipment and the pipeline must be well sealed to prevent material leakage. A bypass pipeline should also be installed to facilitate equipment maintenance without affecting normal production.

Fifthly, after installation, a no-load test run should be performed to check whether the equipment runs smoothly and without abnormal noise, and whether the electrical system is normal. For suspended magnetic separators, the stability of the suspension structure should be checked, and for roller-type magnetic separators, the smooth operation of the belt should be checked.

B. Maintenance of Iron Separators

1. Daily Maintenance

Daily maintenance is crucial for extending the service life of iron separators and ensuring stable equipment operation. This should be the responsibility of a designated person, who should perform relevant inspections and maintenance work daily. First, conduct a visual and operational check. Before starting the machine each day, check whether the main body, support frame, and connecting parts of the iron separator are intact, and whether there are any loose, deformed, or damaged parts. During operation, observe whether the equipment is running smoothly and without abnormal vibrations or noises. For suspended iron separators, check whether the distance between the belt and the equipment is normal and whether there is any friction. At the same time, check whether the indicator lights and meters of the electrical control cabinet are working properly and whether there are any alarm signals. Second, promptly clean up ferromagnetic impurities. For manually cleaned iron separators, the iron impurities adsorbed on the equipment surface should be cleaned regularly (usually every shift) to prevent excessive accumulation of impurities from affecting the iron separation effect. For automatically cleaned iron separators, check the operating status of the cleaning device (such as scrapers and discharge belts) to ensure that impurities are discharged smoothly. If the cleaning is incomplete, adjust the position of the cleaning device or replace worn parts. Third, check the lubrication. For equipment with rotating parts, such as drum-type iron separators and belt-type cleaning devices, check the lubrication status of the bearings daily to ensure sufficient lubrication and no leakage. If the lubricating oil is found to be deteriorated or insufficient, replace or replenish it promptly to prevent bearing wear. Finally, perform daily cleaning. Regularly clean dust, debris, and oil stains from the equipment surface, especially electrical components and heat dissipation devices, to prevent dust accumulation from causing poor heat dissipation or electrical failures.

2. Regular Overhaul

In addition to daily maintenance, a regular overhaul plan should be developed based on the equipment's operating conditions and instructions for use, usually including monthly, quarterly, and annual overhauls. Monthly overhauls focus on checking the core components of the equipment, including the magnetic system, coils, and bearings. For permanent magnet iron separators, check whether the surface of the magnetic system is damaged or demagnetized; this can be tested by simple methods such as attracting iron nails to test the magnetic field strength. For electromagnetic iron separators, check whether the insulation layer of the coil is intact and whether there is any aging or damage. At the same time, measure the resistance value of the coil and compare it with the factory parameters. If the deviation is large, troubleshoot the fault promptly. Quarterly maintenance requires a complete disassembly and inspection of the equipment, replacement of severely worn parts (such as bearings, seals, and scrapers), and rust removal and anti-corrosion treatment of brackets and connectors. For the electrical system, the integrity of components such as contactors, relays, and fuses in the control cabinet should be checked, loose terminals should be tightened, and dust should be cleaned from the control cabinet. Annual maintenance requires in-depth maintenance, including a comprehensive inspection of the magnetic system of the iron separator. If the permanent magnets are severely demagnetized, they should be replaced or remagnetized promptly; a pressure test should be performed on the coils of the electromagnetic iron separator to ensure electrical safety; at the same time, the overall performance of the equipment should be evaluated, and equipment parameters should be adjusted according to operating conditions to ensure that the iron removal effect meets production requirements.

3. Maintenance in Special Environments

Iron separators operating in special environments such as high temperature, high humidity, high dust, and strong corrosiveness require enhanced maintenance and targeted protective measures. In high-temperature environments (such as near boilers and dryers), heat dissipation management of the equipment should be strengthened, and heat dissipation devices should be cleaned regularly to prevent coil damage due to overheating. High-temperature resistant insulation materials and lubricants should also be used; in humid environments, moisture protection of electrical components should be strengthened, and the grounding of the equipment should be checked regularly to prevent leakage accidents. The equipment surface should be regularly painted with anti-rust paint to prevent corrosion; in dusty environments, the cleaning frequency should be increased to prevent dust from entering the equipment and wearing down components or affecting heat dissipation. A dust cover can be installed on the outside of the equipment; in corrosive environments, corrosion-resistant iron separators should be selected, or the equipment surface should be treated with anti-corrosion treatment (such as spraying an anti-corrosion coating). The corrosion of the equipment should be checked regularly, and damaged anti-corrosion layers should be repaired promptly.

4. Common Fault Handling

Various faults may occur during the operation of the iron separator, which need to be promptly investigated and resolved to ensure that the equipment quickly resumes operation. Common faults and their handling methods are as follows: First, reduced iron removal effect. Possible reasons include weakened magnetic field strength, excessive distance between the equipment and the material, excessive accumulation of iron impurities, and magnetic field interference. Troubleshooting methods: For permanent magnet separators, check if the magnetic system is displaced or demagnetized. If demagnetization is severe, the magnetic system needs to be replaced. For electromagnetic separators, check if the coil is damaged and if the power supply voltage is stable. Repair the coil or adjust the power supply voltage as needed. Adjust the distance between the separator and the material, and clean iron impurities from the equipment surface to avoid magnetic field interference between multiple devices. Secondly, if there are abnormal noises during equipment operation, possible causes include bearing wear, loose components, unbalanced rollers, and belt friction. Troubleshooting methods: Check the bearing condition, replace worn bearings and add lubricating oil; tighten loose connecting parts; perform balance calibration on the rollers; adjust the belt position to avoid friction with the equipment. Thirdly, electrical faults (such as control cabinet alarms, equipment failure to start) may be caused by coil short circuits or open circuits, loose wiring, damaged fuses, or power supply failures. Troubleshooting methods: Disconnect the power supply, check the insulation performance and resistance value of the coil, repair or replace the damaged coil; tighten the wiring terminals; replace damaged fuses; check the power supply voltage to ensure a stable power supply. Fourthly, automatic cleaning device malfunctions may be caused by worn scrapers, slipping discharge belts, or drive motor failures. Troubleshooting methods: Replace worn scrapers; adjust the belt tension and clean oil stains from the belt surface; check the drive motor, repair or replace the faulty motor.

The installation and maintenance of iron separators must strictly follow technical specifications. Thorough preparation should be made before installation, key aspects should be controlled during installation, and maintenance and inspection should be strengthened during daily operation to promptly address various faults. Only in this way can the long-term stable operation of the iron separator be ensured, fully utilizing its iron removal efficiency and providing a guarantee for the safe and efficient operation of the production process. In practical applications, it is also necessary to develop customized installation and maintenance plans based on the on-site production conditions and equipment model to further improve the reliability and economic efficiency of the equipment.

Save Time! Get A Detailed Quotation Quickly.