The iron remover is an important industrial equipment, which can produce strong magnetic attraction, and is used to remove the ferromagnetic impurities mixed in the material, so as to ensure the safe and normal operation of the mechanical equipment in the conveying system, such as crusher and grinding machine. The following is a detailed introduction to the knowledge and skills of purchasing the iron remover:

A. Basic knowledge of iron remover purchase

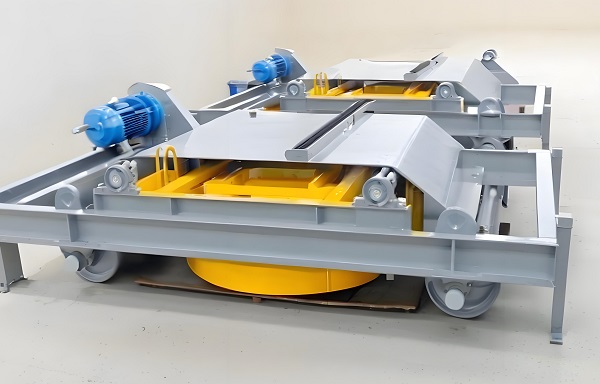

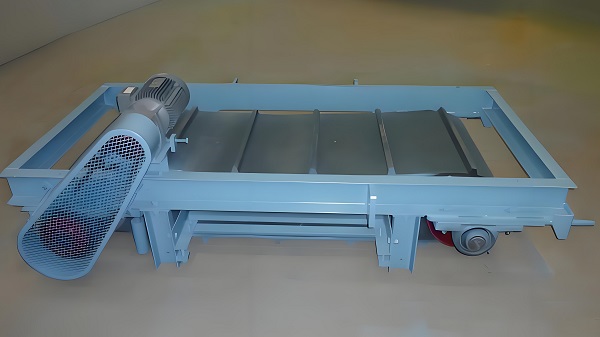

Iron Remover

The iron remover is mainly divided into electromagnetic iron remover and permanent magnetic iron remover. Electromagnetic iron remover generates magnetic field through electromagnet, which is applicable to occasions where magnetic field strength is frequently adjusted or large amount of materials are handled. Permanent magnetic separator generates permanent magnetic field with permanent magnetic materials, which is applicable to the situation requiring long-term stable operation.

The iron remover can also be divided into manual iron unloading, automatic iron unloading and program control iron unloading according to the iron unloading mode. Manual iron unloading is applicable to materials with less iron content and low requirements on iron removal efficiency; Automatic iron unloading and program control iron unloading are applicable to the situation where the material contains more iron and requires efficient iron removal.

Clarify the purchase demand

Before purchasing the iron remover, the material property, iron content, iron removal requirements, service environment and other factors shall be determined. For example, the material moisture, thickness, particle size and the nature of the ferromagnetic matter will affect the selection of the separator.

Determine the installation position and size of the iron remover and the matching method with other equipment according to the production process and requirements.

B. Key tips for selecting separator

Iron Remover

Select according to the iron content of the material

When the iron content in the material is large, the iron remover with high magnetic field intensity and strong processing capacity shall be selected, such as RCDC, RCDD, RCDF series, etc. These series usually have a large magnetic field range and high iron removal efficiency, which can meet the removal requirements of a large number of ferromagnetic impurities.

When the iron content in the material is small, the iron remover with moderate magnetic field intensity and easy operation can be selected, such as RCDA, RCDB, RCDE series, etc. These series have low cost and maintenance requirements while guaranteeing the iron removal effect.

Consider material thickness and properties

For thick materials, suspended electric and permanent magnetic iron removers can be used together with WCTG series five-time parallel roller to improve iron removal rate. In this way, the contact area between the material and the magnetic field can be increased, so as to improve the iron removal effect.

If the materials contain materials that cannot be adsorbed by the iron remover (such as non-ferromagnetic impurities), the metal detector shall be used for detection. When such metal is detected, manual iron removal shall be carried out after automatic shutdown to ensure the accuracy and safety of the iron removal process.

Adapt to site working environment

Dust, humidity, temperature and other factors of the site environment will affect the operation of the iron remover. Therefore, these factors shall be taken into consideration when selecting and selecting the iron remover with corresponding protective measures.

If the site environment is dusty, a fully enclosed iron separator shall be selected to prevent the dust from entering the equipment and affecting the performance. In the environment with high humidity, the iron remover with good moisture-proof performance shall be selected.

Focus on equipment quality and performance

The quality and performance of iron remover are directly related to its service life and iron removal effect. Therefore, attention shall be paid to the manufacturing process, material selection, performance parameters and other indicators of the equipment during procurement.

The selection of iron remover with high quality manufacturing process and materials can ensure its high strength and abrasion resistance and extend its service life. At the same time, pay attention to performance parameters such as magnetic field intensity, processing capacity, etc. to ensure that the equipment can meet the production requirements.

Consideration of ease of installation and maintenance

The installation and maintenance convenience of iron remover is also an important factor to be considered when selecting. Equipment easy to install, commission and maintain shall be selected to reduce operation cost and improve work efficiency.

During the purchase, you can know the installation requirements, commissioning steps and maintenance period of the equipment, so as to better operate and manage the equipment in the actual use process.

C. Precautions for purchase of electromagnetic separator

Iron Remover

The qualification and reputation of the supplier shall be known when purchasing the iron remover. Select suppliers with legal qualification, professional technology and good reputation to ensure the purchase of equipment with reliable quality and stable performance.

Qualification and reputation can be assessed by referring to relevant certificates of suppliers, knowing their reputation in the industry and cooperation with other customers.

Compare different brands and models

When selecting the iron remover, compare the equipment of different brands and models to select the equipment most suitable for your needs. The performance parameters, price and after-sales service of the equipment can be compared.

At the same time, the purchase experience and evaluation of other customers can also be referred to, so as to understand the performance and use of the equipment more comprehensively.

Conduct field test and verification

It is preferred that field tests and verifications be performed prior to purchasing the separator. Observe the iron removal effect, operation stability and noise through the actual operation of the equipment, so as to understand the performance and quality of the equipment more intuitively.

If possible, professionals can also be invited to carry out on-site test and evaluation to ensure that the purchased equipment can meet the production requirements and quality requirements.

Iron Remover

After-sales service and support of iron remover are also important factors to be considered during purchase. Suppliers who can provide timely and professional after-sales services shall be selected to ensure that problems encountered in the use process can be solved in time.

The after-sales service policy, maintenance response time, supply of spare parts and other information of the supplier can be learned, so as to obtain better support and guarantee in the actual use process.

PS: The knowledge and skills for the purchase of iron remover involve many aspects, including removing the type of iron remover, clarifying the purchase demand, selecting according to the iron content of the material, considering the thickness and nature of the material, adapting to the on-site working environment, paying attention to the quality and performance of the equipment, considering the convenience of installation and maintenance, understanding the qualification and reputation of the supplier, comparing different brands and models, conducting on-site test and verification, and considering after-sales service and support. Through comprehensive consideration of these factors and selection of appropriate equipment, it can be ensured that the iron remover can play the best performance in the actual use process and meet the production requirements.

Save Time! Get A Detailed Quotation Quickly.