With the acceleration of urbanization and the continuous improvement of environmental protection requirements, the resource utilization, reduction, and harmless treatment of waste have become the core development direction of the industry. Waste screening, as a crucial preliminary step in the waste treatment process, aims to classify complex waste components according to their material and particle size, laying the foundation for subsequent incineration, landfill, and recycling processes. Ferromagnetic impurities (such as discarded nails, rebar fragments, aluminum cans, and magnetic components from discarded household appliances) are widely present in waste. If not removed promptly, these impurities can seriously affect the safe operation and efficiency of screening equipment, and even hinder the waste resource utilization process. Magnetic separators, as key equipment specifically designed to remove ferromagnetic impurities, play an irreplaceable role in waste screening systems. This article will start from the pain points of waste screening and elaborate on the core uses, suitable types, application points, and application value of magnetic separators in waste screening, comprehensively analyzing their importance in the waste treatment industry chain.

A. Core Pain Points of Waste Screening and the Significance of Magnetic Separators

The complexity of waste sources determines the diversity of its components. Urban household waste, industrial waste, construction waste, and other types of waste all contain varying proportions of ferromagnetic impurities. During the waste screening process, these impurities can cause a series of problems, becoming the core pain points restricting screening efficiency and safety. Firstly, it causes serious damage to screening equipment. Commonly used waste screening equipment includes vibrating screens, trommel screens, and air separators. These devices contain a large number of rotating parts and screening meshes. When ferromagnetic impurities enter the equipment, they collide violently with the rotating parts, leading to wear and deformation of the parts, or even jamming the equipment, causing downtime for maintenance and significantly increasing equipment maintenance costs and downtime losses. Secondly, it affects screening accuracy and classification efficiency. The presence of ferromagnetic impurities can clog the screening meshes, preventing the waste from being effectively separated according to the preset particle size. At the same time, the impurities mix with other waste components, reducing the purity of the recovered materials and affecting their resource utilization value. Finally, there are serious safety hazards. Ferromagnetic impurities may be thrown out during the high-speed operation of the equipment, causing personal injury to on-site operators. In addition, in the subsequent incineration process, metal objects entering the incinerator can damage the grate, affect incineration efficiency, and even trigger serious accidents such as explosions in the furnace.

The introduction of magnetic separators is a precise solution to the above problems. By rationally configuring magnetic separators in the waste screening process, ferromagnetic impurities in the waste can be removed in advance or simultaneously, avoiding the negative impact of impurities on equipment, efficiency, and safety from the source, providing a guarantee for the stable operation of the waste screening process, and creating favorable conditions for subsequent waste resource utilization. Its significance lies not only in "impurity removal," but also in improving the operational stability, economy, and safety of the entire waste treatment system, and it is an important supporting equipment for the transformation of waste treatment from "extensive" to "refined."

B. Core Uses of Magnetic Separators in Waste Screening

1. Protecting Screening Equipment and Reducing Maintenance Costs

Protecting screening and subsequent processing equipment is the most basic and important use of magnetic separators in waste screening. Ferromagnetic impurities in waste have high hardness, especially steel rebar fragments in construction waste and mechanical parts in industrial waste. If they directly enter equipment such as vibrating screens and trommel screens, they will cause serious wear to key components such as the screen mesh, drum wall, and bearings. For example, the screen mesh of a vibrating screen is highly susceptible to holes and deformation due to repeated collisions with metal objects, leading to decreased screening accuracy and requiring frequent screen replacement; if large metal objects enter the drum of a trommel screen, they may jam the drum, causing motor overload and damage. Magnetic separators, by removing ferromagnetic impurities before or during the screening process, prevent contact between impurities and equipment components, significantly reducing equipment wear and malfunctions such as jamming. Practical data shows that a waste screening system with properly configured magnetic separators can reduce equipment failure rates by more Mthan 60%, reduce the replacement frequency of wear parts such as screens and bearings by 50%, and save significant equipment maintenance and spare parts costs annually.

Furthermore, magnetic separators also protect downstream equipment such as crushers and incinerators. After waste screening, some materials need to be further crushed in a crusher. If ferromagnetic impurities remain in the material, they will severely damage the crusher's hammers, liners, and other components; for waste entering the incinerator, the presence of metal objects will wear down the grate and may even get stuck in the grate gaps, affecting the normal operation of the grate and reducing incineration efficiency. The pre-separation function of magnetic separators effectively avoids these problems, ensuring the safety of the entire waste treatment process equipment.

2. Improving Screening Accuracy and Ensuring Classification Quality

The core objective of waste screening is to achieve precise separation of different waste components, providing high-quality raw materials for subsequent resource utilization. The presence of ferromagnetic impurities seriously interferes with the screening effect. On the one hand, small metal objects may clog the screen holes of the screening equipment, preventing waste materials from passing through smoothly according to the preset particle size, leading to "poor screening" and reduced screening efficiency; on the other hand, metal objects mixed with plastic, paper, organic matter, and other waste components will reduce the purity of the subsequent recycled materials. For example, in the plastic recycling process, if metal objects are mixed with the plastic, it will affect the melting and processing quality of the plastic, leading to a decrease in the performance of the finished product; in the resource utilization of organic matter, the inclusion of metal objects will increase the difficulty of subsequent processing and reduce the quality of products such as organic fertilizers. Magnetic separators can precisely attract ferromagnetic impurities from waste, achieving effective separation of impurities from other waste components, thereby improving screening accuracy. By rationally setting the installation position and adsorption strength of the magnetic separator, it can ensure that ferromagnetic impurities of different particle sizes and shapes are effectively removed, preventing impurities from blocking the screen holes and ensuring the smooth operation of the screening equipment. At the same time, the waste materials after iron removal are classified more accurately, resulting in higher purity of recycled plastics, paper, metals, and other raw materials, significantly increasing their resource utilization value. For example, plastic fragments treated by a magnetic separator can directly enter the recycling process without the need for additional impurity removal steps, reducing resource processing costs.

3. Eliminating Safety Hazards and Ensuring Production Safety

The waste screening site environment is complex, and the equipment is mostly in a high-speed operation state. The presence of ferromagnetic impurities can bring multiple safety hazards. First, for operators, high-speed screening equipment may throw out mixed iron objects, forming "high-speed projectiles," which can easily cause personal injury to on-site workers; secondly, if iron objects enter electrical equipment or high-temperature environments, it may trigger more serious safety accidents. For example, iron objects contacting the electrical lines of the screening equipment may cause short circuits and leakage, leading to electric shock or fire accidents; in the screening process before waste incineration, if iron objects are not removed, they may collide with high-temperature components in the incinerator after entering the furnace, generating sparks, or even causing an explosion in the furnace.

Magnetic separators eliminate these safety hazards at the source by promptly removing ferromagnetic impurities. On the one hand, it prevents iron objects from being thrown out during equipment operation, ensuring the personal safety of operators; on the other hand, it prevents iron objects from entering electrical equipment or high-temperature environments, avoiding serious accidents such as short circuits, fires, and explosions. In addition, the stable operation of the magnetic separator can reduce sudden shutdowns of screening equipment caused by impurity blockage, avoiding production interruptions and safety risks caused by equipment failures, providing strong support for stable and safe production at the waste screening site.

4. Recycling Magnetic Metals and Improving Resource Utilization Efficiency

The ferromagnetic impurities in waste are not "useless." The scrap iron and steel contained in them have high recycling value and are important recyclable resources. In waste sorting systems without magnetic separators, these magnetic metals are often landfilled or incinerated along with other waste, wasting valuable resources and increasing processing costs. Magnetic separators, while removing impurities, enable the precise recovery of magnetic metals. The collected iron objects are then sent to specialized institutions for recycling, achieving resource circularity.

For large-scale waste treatment plants, the daily amount of waste processed can reach hundreds or even thousands of tons, containing a considerable amount of magnetic metals. Recovering these metals with magnetic separators can bring additional economic benefits to enterprises, offsetting some of the equipment operation and maintenance costs. Taking urban household waste treatment as an example, each ton of waste contains approximately 0.5-2 kilograms of magnetic metals. If a waste treatment plant processes an average of 2000 tons of waste per day, it can recover 1-4 tons of magnetic metals daily using magnetic separators. Based on market prices for recycled metals, this can generate considerable economic revenue annually. At the same time, the recovery of magnetic metals reduces the amount of waste going to landfills, lowering the pressure on landfill capacity, and meeting the requirements of waste reduction, thus providing both economic and environmental benefits.

C. Suitable Types and Application Key Points of Magnetic Separators in Waste Sorting Scenarios

1. Selection of Suitable Magnetic Separator Types

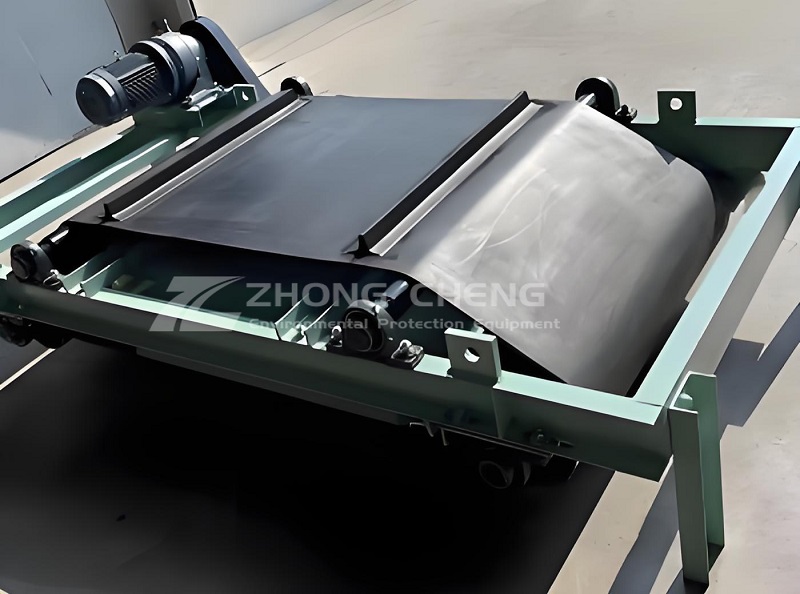

The unique characteristics of waste sorting scenarios (complex waste composition, high humidity, diverse impurity forms, and large processing volume) dictate higher performance requirements for magnetic separators. The appropriate type must be selected based on the specific sorting process and waste characteristics. Currently, the commonly used iron separators in waste sorting mainly include the following types: First, suspended permanent magnet iron separators, suitable for waste conveyed by belt conveyors. They can be suspended above the belt, requiring no changes to the existing conveyor line, are easy to install, and consume no electricity, resulting in low operating costs. They are suitable for removing small to medium-sized ferromagnetic impurities from waste; second, drum-type permanent magnet iron separators, which can directly replace the rollers of belt conveyors, performing impurity removal simultaneously during waste conveyance. They have high impurity removal efficiency and can adapt to high-humidity and dusty waste environments, making them suitable for continuous operation in large-scale waste sorting lines; third, electromagnetic iron separators, which generate a strong magnetic field through electrification, providing strong adsorption capabilities. The magnetic field strength can be adjusted according to the iron content in the waste, making them suitable for waste treatment scenarios with high iron content and complex types of iron impurities. However, their operation requires electricity and requires moisture and dust protection; fourth, pipeline-type iron separators, suitable for the sorting process of powdered or granular waste. They can be installed inside pipelines, achieving impurity removal in a closed environment, preventing the spread of waste dust, and ensuring a clean working environment. 2. Key Application Points

To ensure that the magnetic separator functions effectively in waste screening, the following key application points must be considered: First, select a suitable installation location, preferably in the conveying section before the waste enters the screening equipment (such as the middle section of a belt conveyor), to ensure that ferrous materials are removed before entering the screening equipment; if there are many large pieces of ferrous material in the waste, a large suspended magnetic separator can be added before the coarse screening to remove large pieces of ferrous material first, and then a smaller magnetic separator can be configured before the fine screening to achieve graded impurity removal; second, adjust the appropriate adsorption distance and magnetic field strength. The distance between the suspended magnetic separator and the belt surface needs to be adjusted according to the thickness of the waste, usually controlled at 150-300mm. The magnetic field strength needs to be adjusted according to the size of the ferrous material and the humidity of the waste to ensure the adsorption effect; third, implement moisture-proof and anti-corrosion treatment. The waste screening site has high humidity, and some waste is corrosive. Therefore, a magnetic separator with moisture-proof and anti-corrosion properties should be selected. The equipment surface needs to be regularly coated with an anti-corrosion coating, and the electrical components need to be sealed and protected; fourth, configure an automatic cleaning device. Due to the high content of ferrous materials in the waste, manual cleaning is inefficient. Therefore, automatic cleaning devices such as scrapers and iron-removing belts should be used to achieve continuous removal of ferrous materials and prevent the accumulation of impurities from affecting the impurity removal effect; fifth, perform regular maintenance and calibration. Due to the harsh waste environment, daily maintenance of the magnetic separator should be strengthened. Regularly clean the waste residue and dust on the equipment surface, and check the performance of the magnetic system. If a decrease in magnetic field strength is found, remagnetization or replacement of the magnetic system is required. D. Application Value and Development Trends of Magnetic Separators in Waste Screening

The application of magnetic separators in waste screening not only solves core problems such as equipment protection, efficiency improvement, and safety assurance, but also aligns with the development trend of waste resource utilization. Its application value is mainly reflected in three aspects: firstly, economic value, by protecting equipment, reducing maintenance costs, recovering magnetic metals to create additional revenue, and improving screening efficiency to reduce labor costs, significantly enhancing the economic benefits of waste treatment enterprises; secondly, environmental value, assisting in accurate waste classification and resource utilization, reducing landfill and incineration volumes, and lowering environmental pollution. Simultaneously, the recycling of magnetic metals reduces the mining of raw materials, aligning with the concept of green development; thirdly, social value, ensuring production safety at waste treatment sites, improving waste treatment efficiency, alleviating urban waste treatment pressure, and providing strong support for urban development.

With the continuous upgrading of waste treatment technologies, the application of magnetic separators in waste screening also shows a clear development trend: firstly, intelligence, future magnetic separators will integrate technologies such as sensors and the Internet of Things to achieve automatic adjustment of magnetic field strength, real-time fault warning, and intelligent control of the cleaning process, improving the automation level of equipment operation; secondly, high efficiency, in response to the need to remove small iron objects and weakly magnetic impurities in waste, magnetic separators with higher magnetic field strength and wider adsorption range will be developed to improve impurity removal accuracy and efficiency; thirdly, multi-functionality, magnetic separators will be integrated with screening and crushing equipment, combining impurity removal with material conveying and classification functions, further optimizing the waste treatment process.

Magnetic separators play a dual role as "protector" and "resource recycler" in waste screening. Their core uses include equipment protection, accuracy improvement, safety assurance, and resource recovery, making them indispensable key equipment in the waste treatment process. With the continuous improvement of environmental protection requirements and the continuous development of waste resource utilization technologies, the application scenarios of magnetic separators will become more extensive, and their performance will be continuously upgraded, providing important support for the high-quality development of the waste treatment industry. In practical applications, it is necessary to reasonably select the type of magnetic separator based on waste characteristics, screening process, and equipment requirements, and strictly control installation and maintenance points to ensure that it fully plays its role and achieves a balance of economic, environmental, and social benefits.

Save Time! Get A Detailed Quotation Quickly.