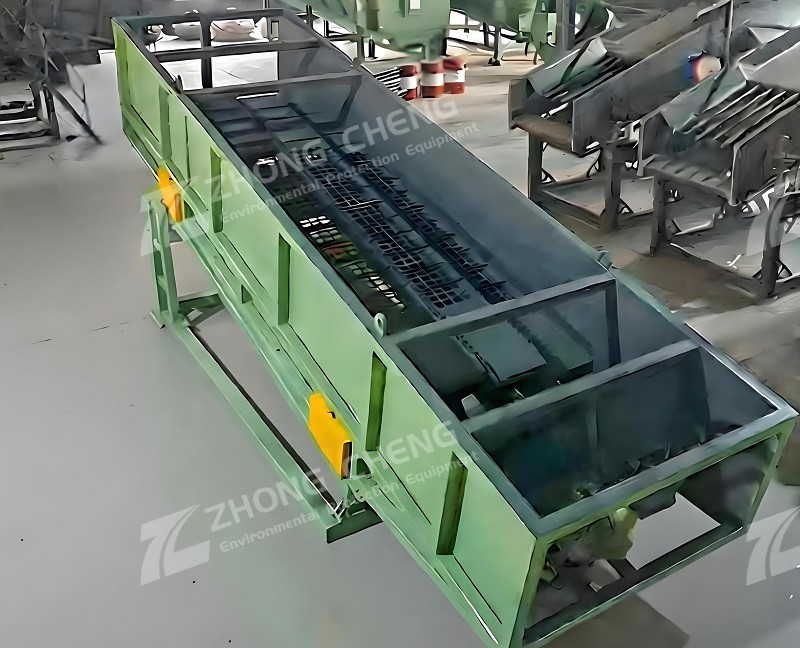

The ballistic screen is a key classification equipment in the field of solid waste sorting and resource recovery. It achieves separation through the bouncing motion of the screen surface and the differences in the physical properties of the materials. Its efficiency directly affects the capacity of subsequent processes and the quality of resource recovery. Currently, problems such as complex materials and fluctuating humidity can easily lead to screen clogging and uneven sorting, limiting operational efficiency. Based on industry practices, a systematic approach can be taken from four dimensions—material pretreatment, parameter adjustment, structural upgrading, and enhanced operation and maintenance—to improve the screening efficiency of ballistic screens, while ensuring equipment stability and production economics, thus meeting the needs of solid waste resource utilization.

As a core equipment in solid waste sorting and resource recovery, the ballistic screen relies on the differences in material physical properties and the bouncing motion of the screen surface to achieve classification and separation. Its screening efficiency directly determines the capacity of subsequent processing steps and the quality of resource recovery. Currently, when dealing with materials with complex compositions and fluctuating humidity, traditional ballistic screens are prone to problems such as screen clogging and uneven sorting, limiting operational efficiency. Based on industry practices and technological innovation experience, a systematic approach can be taken from four dimensions—material pretreatment, equipment parameter adjustment, structural optimization and upgrading, and enhanced operation and maintenance management—to improve the screening efficiency of ballistic screens, while ensuring both stability and economic efficiency.

Effective material pretreatment lays the foundation for efficient screening. The particle size distribution, humidity, and cleanliness of the material are the primary factors affecting screening efficiency. Pretreatment can reduce the burden on the equipment from the source. For materials with excessive impurities, a pretreatment device should be added before the ballistic screen to remove entangled and damaging impurities such as ropes and large hard objects, preventing them from jamming the screen body or damaging the screen surface, thus ensuring normal operation of the equipment. For materials with high humidity and a tendency to clump together, drying and dehumidification or adding an appropriate amount of dispersant can be used to reduce material viscosity and prevent screen clogging—especially when processing municipal solid waste, high humidity is a key factor limiting efficiency. Controlling the moisture content within a reasonable range through pretreatment can significantly improve stratification and screening effectiveness. At the same time, it is necessary to ensure uniform feeding. By adjusting the feeding speed and distribution device, the material should be evenly distributed across the screen surface to avoid local overloading or missed screening, making full use of the effective screening area.

Optimize equipment operating parameters to meet material characteristics requirements. The core operating parameters of a ballistic screen directly determine the material's trajectory and separation effect, requiring dynamic adjustment based on material characteristics. The screen surface inclination needs to balance material conveying speed and screening time; an excessively large angle can lead to the material sliding too quickly, resulting in insufficient screening; a too small angle can cause material accumulation, reducing processing efficiency. Generally, the angle needs to be adjusted within the range of 15°-30°. Vibration frequency and amplitude must match the material density and particle size. When processing lightweight, fine materials, a high-frequency, low-amplitude mode is used to promote material stratification and reduce clogging; when processing heavy, large materials, a low-frequency, high-amplitude mode is selected to enhance the bouncing force and achieve effective separation of light and heavy materials. With variable frequency drives and PLC automatic control systems, real-time parameter adjustment is possible, even adaptive optimization based on changes in material composition, avoiding the problem of insufficient adaptability of fixed parameters and improving adjustment accuracy and operational stability.

Upgrading equipment structural components strengthens screening performance. By optimizing structural design and replacing high-performance components, screening efficiency and equipment durability can be fundamentally improved. The screen surface is the core of screening; traditional screen surfaces are prone to wear and clogging. They can be replaced with high-manganese steel wear-resistant screen surfaces or polyurethane elastic screen surfaces. The former improves impact resistance, while the latter reduces material adhesion. Special coatings can also be applied to further optimize anti-clogging effects. To address screen hole clogging, a bouncing ball cleaning device can be added, utilizing high-frequency impact of bouncing balls on the bottom of the screen to dislodge clogged material, or an integrated high-pressure airflow self-cleaning module can be used to remove debris from the screen holes in real time, especially suitable for fine material screening. Furthermore, using a three-layer sorting or modular design allows for multi-level simultaneous screening, increasing throughput, and facilitating equipment upgrades and component replacement, adapting to different scales and material screening needs. Intelligent ballistic screening systems, by integrating AI vision recognition and precise airflow sorting modules, can achieve precise material classification, improving efficiency by more than 30% compared to traditional equipment.

Strengthening daily operation and maintenance management ensures long-term stable operation of the equipment. A comprehensive operation and maintenance system is an important guarantee for efficient screening, requiring the establishment of a regular inspection and maintenance mechanism. Regularly inspect the screen surface condition and promptly replace damaged or deformed screens and bouncing balls to prevent reduced screening efficiency due to component damage. Clean accumulated material and debris from inside the screen body, and check the lubrication and tightness of key components such as the vibrating motor and bearings to reduce downtime due to malfunctions. Establish equipment operation logs to record parameter settings, throughput, and fault information. Use data analysis to optimize operating procedures and develop standardized operating procedures adapted to different materials. Simultaneously, strengthen operator training to improve parameter adjustment and troubleshooting capabilities, preventing reduced efficiency or equipment damage due to improper operation – for example, promptly identifying and addressing issues such as screen body imbalance and bearing overheating can effectively reduce potential failures and extend equipment maintenance intervals to over 2000 hours.

Improving the screening efficiency of bouncing screens requires a comprehensive approach encompassing material pretreatment, parameter optimization, structural upgrades, and operation and maintenance management, developing customized solutions based on material characteristics and operational needs. With the development of intelligent and energy-saving technologies, integrating intelligent control systems and multi-technology integration can achieve precise control and improved efficiency in the screening process, reducing operating costs and increasing resource recovery rates. This aligns with the industry development needs of waste sorting and solid waste resource utilization, providing strong support for waste reduction and resource recovery.

Improving bouncing screen screening efficiency requires a multi-dimensional collaborative approach: material pretreatment lays the foundation, parameter optimization adapts to material characteristics, structural upgrades strengthen core performance, and operation and maintenance management ensures long-term operation. Each link needs to be flexibly adjusted according to actual production conditions, avoiding the limitations of single-factor optimization. With the integration of intelligent technologies, intelligent control and standardized operation and maintenance can further unleash the potential of the equipment, reducing operating costs and increasing resource recovery rates, providing reliable technical support for waste reduction and solid waste resource utilization, and contributing to the green and efficient development of the industry.

Save Time! Get A Detailed Quotation Quickly.