With the increasing demand for harmless and resource-efficient treatment of municipal solid waste, the accuracy of front-end screening has become crucial for the efficiency of subsequent processing. Rotary screens, as a core piece of equipment in waste pretreatment, are widely used in various municipal solid waste treatment scenarios due to their wide adaptability and stable operation. They utilize a tilted rotating screen drum structure, combining material weight and centrifugal force, to achieve the separation of waste based on different particle sizes. This solves the problem of complex composition and easy clogging of mixed waste, laying a solid foundation for subsequent processes such as magnetic separation, composting, and incineration, and is an important piece of equipment for promoting waste reduction and resource utilization.

In the front-end pretreatment stage of municipal solid waste resource utilization, rotary screens, with their strong adaptability, resistance to clogging, and stable operation, have become the core screening equipment. They primarily achieve the initial separation of municipal solid waste through particle size classification, laying the foundation for subsequent processes such as magnetic separation, air separation, composting, or incineration. The core logic is to use a tilted rotating screen drum, combined with material weight and centrifugal force, to classify waste of different particle sizes. This adapts to the complex composition and fluctuating moisture content of mixed municipal solid waste and is widely used in the treatment of both fresh and aged waste.

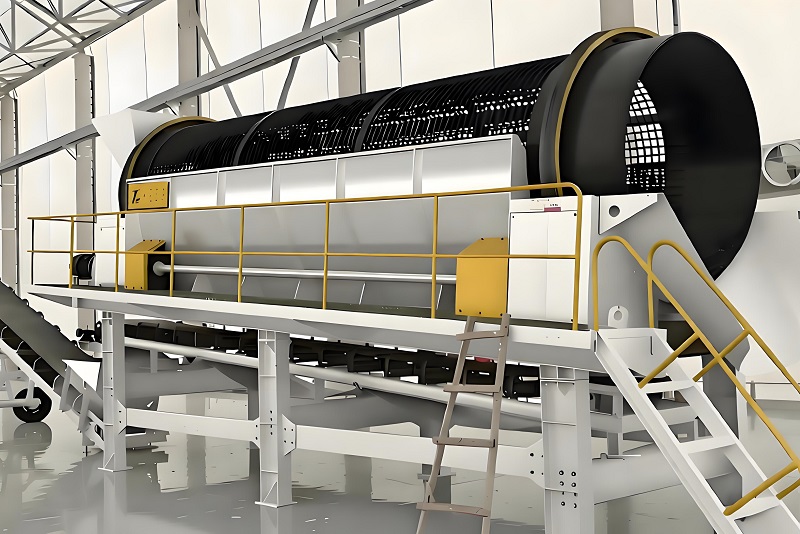

The structural design of the rotary screen is tailored to the needs of municipal solid waste screening. It mainly consists of a drive system, screen drum device, support mechanism, feeding and discharging devices, and auxiliary protection devices. The drive system includes a motor and a reducer, which can adjust the rotation speed to a low range of 3-8 revolutions per minute, avoiding insufficient material screening or increased equipment wear caused by high-speed rotation. The screen drum adopts a multi-section design, with the aperture size increasing from the feeding end to the discharging end. Common aperture sizes are divided into three levels: 10-20mm, 30-50mm, and 80-100mm, which can be flexibly adjusted according to waste treatment needs. The screen plates are made of high-quality steel plates with anti-corrosion and strengthening treatment, possessing both acid and alkali resistance and wear resistance, resulting in a longer service life. The support mechanism uses support rollers to support the screen drum, eliminating the traditional central shaft design of shaftless rotary screens, which better prevents entanglement of long, fibrous waste and adapts to the screening needs of flexible materials such as plastic ropes and fabrics in municipal solid waste. In addition, the equipment is equipped with a sealed cover, a spraying device, and a brush cleaning mechanism, combining dust and odor control with anti-clogging functions, meeting environmental protection standards.

The entire process of screening municipal solid waste using the trommel screen relies on three main stages: pre-treatment, graded screening, and auxiliary anti-clogging, forming a closed-loop operation to ensure screening efficiency and effectiveness. The pre-treatment stage is the prerequisite. After municipal solid waste is transported to the treatment plant by garbage trucks, it is first uniformly conveyed to a bag breaker via a plate feeder to break open the garbage bags, allowing food waste, plastics, bricks, and other materials to be fully exposed, preventing fine materials inside the bags from affecting screening accuracy due to lack of contact with the screen holes. At the same time, large debris such as furniture and discarded appliances are removed during the pre-treatment stage to prevent them from entering the screen drum and causing equipment jamming, ensuring a smooth screening process.

Graded screening is the core stage. The pre-treated mixed waste is fed into the inclined screen drum through a hopper. The motor drives the screen drum to rotate slowly through a reducer. The waste undergoes two movements simultaneously within the screen drum: first, axial movement along the screen drum axis, gradually moving towards the discharge end due to the gravitational force component generated by the screen drum's inclination angle; second, circular motion perpendicular to the axis. Under the action of centrifugal force and the lifting plates on the inner wall of the screen drum, the waste is continuously thrown up and tumbled, allowing materials of different particle sizes to fully contact the screen surface. Materials with a particle size smaller than the current screen section's aperture, such as food waste fragments, fine soil, and small glass particles, will pass through the screen holes and fall into the corresponding receiving hopper, completing the primary screening; materials with a particle size larger than the screen holes will continue to rotate with the screen drum and enter the next screen section with a larger aperture, achieving secondary or multiple grading. Finally, large pieces of waste that have not passed through all screen sections, such as plastic bottles, wood, fabrics, and bricks, are discharged from the end of the screen drum and enter subsequent manual sorting or secondary crushing stages.

The auxiliary anti-clogging stage is crucial for ensuring the continuity of screening. To address the problem of municipal solid waste containing a large amount of food waste and high moisture content, which easily causes screen holes to clog, the trommel screen uses multiple designs to overcome the clogging problem. On the one hand, the tumbling motion of the material inside the screening drum utilizes centrifugal force to eject materials stuck in the screen holes, achieving self-cleaning; on the other hand, the equipment can be fitted with vibration hammers, hard brushes, or whipping devices to clean the screen surface of adhering materials through mechanical action. Some models are also equipped with a spraying system, combined with bio-enzymatic deodorizers, which can both wash the screen and suppress dust and reduce odors. In addition, the shaftless design fundamentally reduces the problem of entanglement of long, fibrous materials, significantly reducing the frequency of downtime for cleaning compared to traditional shafted trommel screens, and improving processing efficiency.

The screening effect of the trommel screen is affected by multiple parameters, including drum rotation speed, installation angle, screen hole size, and material residence time, all of which require precise control. Excessive rotation speed will cause the material to adhere to the inner wall of the drum due to centrifugal force, preventing sufficient tumbling and screening; too low a speed will cause the material to move too quickly, resulting in incomplete screening. Typically, the highest screening efficiency is achieved when the rotation speed is controlled at 30%-60% of the critical speed. A large installation angle can shorten the material residence time and reduce screening accuracy; a small angle will reduce the processing capacity. The angle needs to be adjusted flexibly according to the waste composition and processing requirements. At the same time, the segmented screen hole design allows for multi-stage screening from small to large, providing clear material stratification for subsequent resource utilization. For example, fine materials can be used for composting, medium-sized materials can be separated for recyclables through magnetic separation and air separation, and large pieces of waste can be used for incineration after crushing, achieving reduction, resource utilization, and harmless treatment of municipal solid waste.

As a "precision screening guardian" in municipal solid waste treatment lines, the trommel screen, with its simple structure, convenient maintenance, and strong adaptability, significantly improves the efficiency of waste pretreatment and reduces the load and energy consumption of subsequent processes. Its single-unit processing capacity can reach 50-300 tons per hour, effectively meeting the needs of different scales of waste treatment plants. The classified waste can be processed in a targeted manner, avoiding resource waste. At the same time, the fully enclosed design controls dust and odor emissions, complying with the "Pollution Control Standard for Municipal Solid Waste Treatment Facilities," providing strong support for ecological environmental protection and public well-being. The rotary screen efficiently screens municipal solid waste by particle size through its scientifically designed structure and classification logic, balancing processing efficiency and environmental requirements. Its collaborative operation mode, encompassing pre-treatment adaptation, multi-stage screening, and intelligent clogging prevention, effectively solves the challenges of mixed waste screening and is adaptable to the needs of different-sized waste treatment plants. As a critical piece of equipment at the front end of the waste treatment chain, the rotary screen not only reduces energy consumption in subsequent processes but also promotes the increased resource utilization rate of municipal solid waste, providing strong support for ecological protection and sustainable development.

Save Time! Get A Detailed Quotation Quickly.