With the accelerating pace of urbanization, the amount of construction waste is continuously increasing. If not properly disposed of, it not only occupies land resources but also poses a long-term threat to the ecological environment. The scientific sorting and resource utilization of construction waste has become a crucial part of green construction and the circular economy. Construction waste screening equipment is widely used in this context. Through processes such as crushing, screening, and sorting, these devices can effectively classify mixed construction waste, providing the foundation for subsequent recycling and significantly improving resource recovery efficiency and the standardization of disposal.

Construction waste, as the main solid waste generated by urban construction and demolition, contains various components such as concrete blocks, bricks, steel bars, wood chips, and soil. Direct landfilling wastes resources and pollutes the environment. Screening is the core link in the resource utilization of construction waste. Through specialized equipment, different components are separated and materials are graded, laying the foundation for subsequent recycling. Currently, there are various types of screening equipment adapted to construction waste, suitable for different processing scenarios and material characteristics. They work together to achieve sorting, grading, and impurity removal, promoting the reduction, resource utilization, and harmless disposal of construction waste, and contributing to the development of the green building materials industry.

Vibrating screens are the basic and most widely used equipment for construction waste screening. Their core function is to grade materials by particle size, separating fine soil and granular materials from larger blocks. They utilize high-frequency vibrations generated by a vibrating motor to cause the construction waste on the screen surface to move in a projectile motion. Fine particles (such as soil and fine sand) that meet the screen mesh size pass through, while larger blocks (concrete blocks, bricks) remain on the screen surface and are transported to the next process. Depending on the processing scale, linear vibrating screens or circular vibrating screens can be selected. Linear vibrating screens are suitable for large-scale continuous operation, providing stable material transport and high grading accuracy; circular vibrating screens have a higher vibration intensity, suitable for materials with slightly higher moisture content, reducing screen clogging, and are often used in the coarse screening stage of construction waste to quickly separate large impurities from fine soil.

Bouncing screens are specialized equipment adapted for separating lightweight and heavy materials in construction waste, compensating for the shortcomings of vibrating screens in separating lightweight impurities. This system utilizes high-frequency bouncing motion of the screen surface to achieve layered separation based on material density differences. Heavy materials (concrete blocks, bricks, and stones) have high inertia and bounce forward with the screen surface, falling into the heavy material channel; light materials (wood chips, plastics, and foam) have low inertia and are easily separated by airflow, falling into the light impurity channel. This equipment is particularly suitable for screening demolition waste, effectively removing lightweight combustible materials and plastic impurities from construction waste, preventing them from affecting product quality during subsequent recycling (such as the production of recycled aggregates), and simultaneously recovering some reusable lightweight materials.

The trommel screen focuses on low-speed, stable screening, suitable for construction waste with high mud content and prone to agglomeration. Its core function is to classify blocky materials and perform fine screening. The main body of the equipment is an inclined rotating drum with screens of different mesh sizes on the drum wall. After the construction waste enters from the feeding end, it tumbles and rotates with the drum, continuously separating during the process: fine particles are screened through the mesh, and blocky materials are gradually screened according to the mesh size, ultimately achieving multi-grade particle size classification. The trommel screen's rotation speed is adjustable, avoiding material splashing caused by high-frequency vibration. It is suitable for the fine screening stage of construction waste, further classifying the blocky materials after coarse screening, providing support for the subsequent classification and utilization of recycled aggregates according to strength grades, and simultaneously reducing the clogging of screen holes by agglomerated materials, improving screening stability.

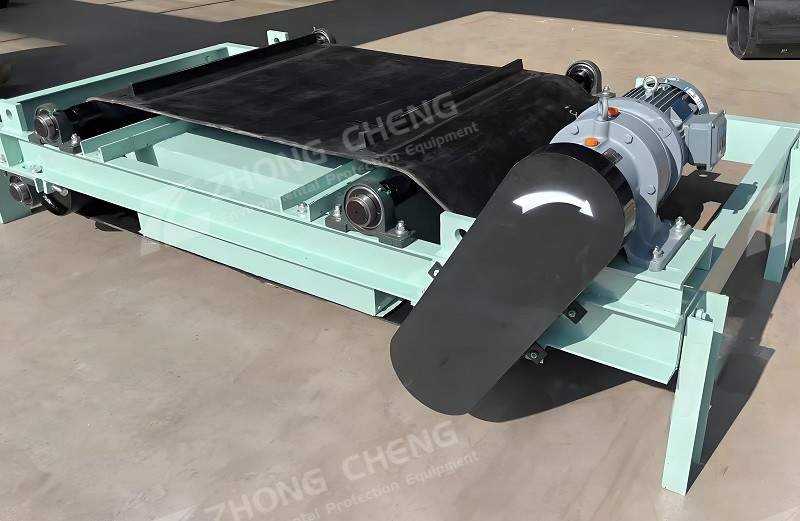

Auxiliary equipment for impurity removal is an important complement to construction waste screening. Although it does not directly participate in particle size classification, it can improve screening purity and subsequent utilization value. Magnetic separators are specifically used to separate magnetic metals from construction waste, especially iron impurities such as rebar and nails. They use a strong magnetic field to attract iron materials, preventing them from entering subsequent crushing and screening equipment, preventing damage to equipment components, and allowing the recovered rebar to be remelted and reused. Air separators are used to enhance the separation of light impurities, working in conjunction with the bouncing screen. Through controllable airflow, they thoroughly separate residual fine lightweight materials (such as wood chips and paper scraps) from the construction waste, improving the purity of heavy materials and ensuring that the quality of recycled aggregates meets standards. Mobile screening equipment is an integrated system designed for outdoor and decentralized construction waste processing. It combines screening, conveying, and impurity removal functions, enabling on-site processing and reducing material transportation costs. These devices integrate vibrating screens, bouncing screens, magnetic separation modules, and conveying devices onto a mobile chassis, allowing for flexible deployment to demolition sites and construction areas. They require no fixed installation and can quickly begin screening operations. Suitable for small-scale, dispersed construction waste processing, they can separate rebar, grade aggregates, and remove impurities on-site, directly producing recycled aggregates for on-site backfilling or transportation to building material factories for further processing. This significantly improves processing efficiency and reduces environmental pollution and costs associated with construction waste transportation.

Various screening equipment working together form a complete construction waste screening system, whose overall function far surpasses the sorting capabilities of a single device. Through multi-stage screening and impurity removal, rebar in construction waste can be recycled, and block materials are processed into different grades of recycled aggregates for use in permeable bricks, road base materials, etc.; fine slag can be used for backfilling and soil improvement; and lightweight impurities can be recycled or incinerated for power generation after harmless treatment. The screening process not only reduces the amount of construction waste sent to landfills, saving land resources, but also replaces natural sand and gravel, alleviating the pressure of building material resource shortages, while simultaneously reducing environmental pollution during construction waste processing, aligning with the "dual carbon" goals and green building development concepts.

Construction waste screening equipment plays a crucial role in the resource utilization of construction waste. Different types of equipment perform their respective functions, achieving efficient separation of concrete, bricks, metals, and impurities. This not only reduces landfill and stacking pressure but also increases the utilization value of recycled aggregates and recyclable materials. With continuous technological advancements, screening equipment is developing towards intelligence, integration, and high efficiency. The rational configuration and use of relevant equipment will provide strong support for the reduction, harmless treatment, and resource utilization of construction waste.

Save Time! Get A Detailed Quotation Quickly.