With the acceleration of urbanization and the advancement of urban renewal projects, the annual output of construction waste continues to rise, making its resource utilization a core path to solving the "garbage siege" and achieving low-carbon development. As a crucial pre-processing step in resource recovery, the construction waste sorting system precisely separates mixed components such as bricks, concrete, metals, and wood, providing high-purity raw materials for subsequent recycling. It is a key equipment cluster determining the efficiency and value of resource recovery. This system is not a single piece of equipment, but a collaborative operating system composed of four modules: pretreatment, core sorting, auxiliary support, and intelligent control. Each module complements the other's functions and connects seamlessly to achieve efficient reduction and resource recovery of construction waste.

I. Pretreatment Module: A Pre-Processing Guarantee for Sorting Construction waste raw materials are complex, often containing large pieces of debris, silt, and moisture. Directly entering the sorting stage can lead to equipment blockage and decreased sorting accuracy. The core function of the pretreatment module is to crush, screen, remove impurities, and dehydrate the raw materials, transforming them into homogeneous materials that meet the requirements of subsequent sorting, providing a fundamental guarantee for the efficient operation of the system. This module mainly consists of feeding equipment, crushing equipment, screening equipment, and pre-removal equipment.

1. Feeding Equipment: Achieving Uniform Raw Material Delivery

The feeding equipment is the "entry point" of the sorting system, responsible for uniformly and continuously conveying the piled construction waste to subsequent equipment, avoiding equipment load fluctuations caused by uneven feeding. Commonly used equipment includes vibrating feeders and plate feeders. Vibrating feeders use high-frequency vibration generated by a vibrator to make the material slide uniformly along the trough, suitable for construction waste with small particle size and no large impurities; plate feeders, with their rigid chain plate structure, can carry large pieces of concrete and brick weighing several tons, and are widely used in the initial conveying of raw construction waste. Their feeding speed can be adjusted by a variable frequency motor to adapt to the needs of different sorting scenarios.

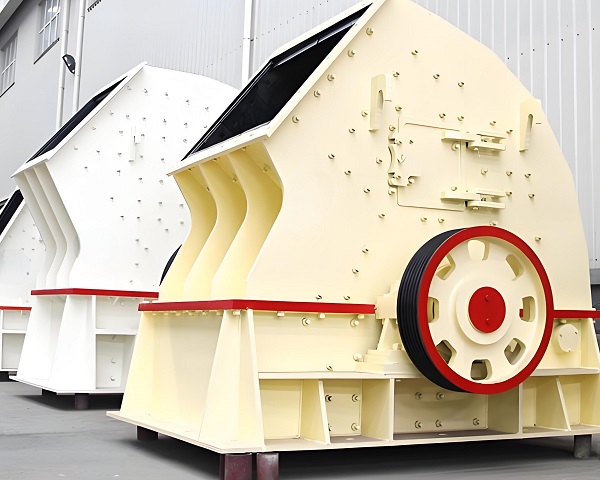

2. Crushing Equipment: Overcoming the Bottleneck of Large Materials

Raw construction waste contains a large number of concrete blocks and wall debris with a particle size exceeding 1 meter. Crushing equipment is needed to reduce the particle size to meet the requirements of subsequent sorting and recycling. Crushing equipment typically adopts a two-stage crushing process of "coarse crushing + medium crushing". Jaw crushers are commonly used for primary crushing, utilizing the squeezing action of the moving and fixed jaws to crush large materials, with the output particle size controllable to within 300 mm. Secondary crushing employs impact crushers or cone crushers, further crushing materials to below 50 mm through impact and shearing, while simultaneously achieving initial separation of concrete and reinforcing steel, creating conditions for subsequent metal sorting. Some systems also include mobile crushing stations, allowing direct operation at the construction waste generation site, reducing transportation costs and environmental pollution.

3. Screening Equipment: Achieving Material Particle Size Classification

Screening equipment is used to classify crushed materials according to particle size, allowing materials of different sizes to enter the corresponding sorting stages, improving sorting accuracy and efficiency. Commonly used equipment includes circular vibrating screens and linear vibrating screens, which separate materials into three grades: coarse (50-100 mm), medium (20-50 mm), and fine (0-20 mm) through screen vibration. Coarse material can be directly used to produce recycled aggregate, medium material requires further impurity separation, and fine material can be used to produce recycled mortar. The screen mesh size can be flexibly adjusted according to production needs, and the equipment is equipped with an automatic screen cleaning device to prevent material from clogging the screen holes.

4. Pre-removal equipment: Removing special impurities

Construction waste often contains lightweight debris such as plastic bags, woven bags, and weeds, as well as brittle impurities such as glass and ceramics. These impurities affect the operation of subsequent sorting equipment and the quality of recycled products, and need to be removed in advance by pre-removal equipment. Lightweight debris is mainly removed by an air separator, which uses airflow to blow lightweight materials to the collection bin, while heavy materials continue to fall; impurities such as glass and ceramics are separated by friction and collision between the glass and the material and the drum screen. Because their density differs greatly from that of concrete, they will accumulate in specific areas during the screening process. Some systems are also equipped with a manual sorting platform, where operators remove special impurities that are difficult to separate automatically, such as batteries and paint buckets.

II. Core Sorting Module: The core force for achieving precise separation

The core sorting module is the "heart" of the entire system. Relying on the physical properties of different materials (such as magnetism, density, conductivity, optical properties, etc.), it uses specialized equipment to achieve precise separation of components such as metal, concrete, wood, and plastic. This module is divided into three main categories based on the different objects to be separated: metal sorting units, inorganic non-metallic sorting units, and organic component sorting units. These units work together to achieve comprehensive separation of construction waste.

1. Metal Sorting Unit: Efficient Recovery of Valuable Metals

The metals in construction waste mainly include ferrous metals such as steel bars, iron wire, and scrap steel, as well as non-ferrous metals such as aluminum alloys and copper, which have extremely high recycling value. The metal sorting unit typically uses a combination of magnetic separation and eddy current separation. Magnetic separation equipment is the core of ferrous metal separation. Commonly used permanent magnet drum separators use a strong magnetic field on the drum surface to attract ferrous metals such as steel bars and scrap steel. These metals are then removed and recycled as the drum rotates to the non-magnetic zone. The magnetic field strength can reach 12,000 Gauss, achieving a recovery rate of over 98% for ferrous metals with a particle size of 5 mm or larger.

Non-ferrous metals are separated using eddy current separators. When the material passes through a high-frequency magnetic field, eddy currents are generated inside the non-ferrous metal, forming a magnetic field opposite to the direction of the magnetic field, thus generating a repulsive force to separate it from the material flow. The sorting efficiency of eddy current separators can be controlled by adjusting the magnetic field frequency and material conveying speed, achieving a recovery rate of over 95% for non-ferrous metals such as aluminum alloys and copper. Some high-end systems are also equipped with metal detectors to monitor the metal content in materials in real time and automatically adjust sorting equipment parameters to ensure effective separation.

2. Inorganic Non-metallic Sorting Unit: Purifying Recycled Aggregate Raw Materials Inorganic non-metallic components are the main part of construction waste, accounting for over 80%, mainly including concrete, bricks, and mortar, and are the core raw materials for producing recycled aggregates. The core task of this unit is to remove impurities from inorganic non-metallic materials and improve the purity of the raw materials. Commonly used equipment includes gravity separators and photoelectric separators. Gravity separators utilize the density difference between concrete and impurities (such as clay and silt). Under the action of water or air flow, heavy concrete particles sink while light impurities float, achieving separation. Photoelectric separators use high-speed cameras to capture the optical characteristics of materials, such as color and shape, and combine AI algorithms to identify differences between concrete and impurities like bricks, stones, and glass. High-pressure airflow is then used to blow away the impurities, achieving a separation accuracy of over 90%.

For materials containing ceramic tiles and stone, some systems are also equipped with X-ray separators. By detecting the elemental composition of the material, different inorganic non-metallic components are distinguished, achieving precise separation of ceramic tiles and concrete, providing support for the differentiated utilization of recycled raw materials. Inorganic non-metallic materials processed by this unit have an impurity content of less than 2% and can be directly used to produce recycled concrete of grade C30 and above.

3. Organic Component Sorting Unit: Separating Recyclable and Combustible Organic Matter

The organic components in construction waste mainly include wood, plastics, paper, and fabrics, which can be divided into recyclable and combustible categories based on their characteristics. This unit achieves classified recycling through air separation, density separation, and photoelectric recognition technology. Lightweight plastics and paper are separated through secondary air separation by a wind-powered separator and then enter a specialized collection device. Wood, due to its significant density difference from concrete, aggregates within a specific particle size range during the vibrating screen grading process, and is then separated by manual assistance or an infrared separator.

For non-recyclable organic waste, such as worn-out fabrics and rotten wood, some systems will transport it to an incineration power generation unit for energy recovery. Recyclable plastics and wood are washed and crushed before being used to produce recycled plastic pellets or engineered wood products, improving resource utilization.

III. Auxiliary Modules: The Supporting System for System Operation

While auxiliary modules do not directly participate in material sorting, they are crucial for ensuring the continuous, stable, and safe operation of the system. These modules mainly include conveying equipment, dust removal equipment, wastewater treatment equipment, and material storage equipment. These devices form a closed-loop system with the core sorting module, achieving zero pollutant emissions and orderly material flow.

1. Conveying Equipment: Building a Material Flow Network

Conveying equipment runs throughout the entire sorting system, responsible for transferring materials between feeding, crushing, screening, and sorting stages, forming a continuous production line. Commonly used equipment includes belt conveyors, screw conveyors, and bucket elevators. Belt conveyors are the most widely used conveying equipment, using combinations of belts of different lengths and angles to achieve horizontal and inclined material transport. Their surfaces are made of non-slip rubber to prevent material slippage. Screw conveyors are mainly used to transport fine or wet materials, such as fine sand after screening or wastewater mixtures after washing. Their enclosed structure prevents material leakage. Bucket elevators are used to lift materials from lower levels to higher storage equipment, such as transporting sorted recycled aggregates to silos.

2. Dust Removal Equipment: Controlling Dust Pollution

The sorting process of construction waste generates a large amount of dust, such as concrete dust generated during crushing and screening. If not controlled, this can cause serious air pollution. The dust removal system adopts a three-stage dust removal process: source suppression + process dust collection + end-of-pipe purification. Source dust suppression utilizes spray dust suppression devices installed at the feed inlet and crushing outlet to adsorb dust using water mist. Process dust collection involves collecting dust generated during equipment operation through dust collection hoods and transporting it via pipelines to a bag filter. End-of-pipe purification consists of a bag filter and activated carbon adsorption device; dust is collected after being filtered through the filter bags, and exhaust gas is treated with activated carbon to remove odors before being discharged in compliance with standards. The dust removal rate can reach over 99%.

3. Wastewater Treatment Equipment: Achieving Water Resource Recycling

The system generates wastewater during material cleaning and dust suppression processes. This wastewater contains a large amount of silt and suspended solids and must be purified by wastewater treatment equipment for recycling, achieving zero discharge. The wastewater treatment process includes bar filtration, sedimentation tank sedimentation, filter tank filtration, and disinfection. The process begins with a screen to remove large impurities from the wastewater. The wastewater then enters a sedimentation tank where flocculants are added to settle the sediment. The supernatant is filtered through a quartz sand filter to remove fine suspended solids. Finally, ultraviolet disinfection kills bacteria, resulting in purified water that meets industrial water standards and can be reused for material washing and dust suppression. The water recycling rate exceeds 95%.

4. Storage Equipment: Ensuring Orderly Material Stacking

Storage equipment is used to store pre-treated raw materials, sorted finished products, and impurities awaiting treatment, preventing material mixing and secondary contamination. Common equipment includes silos and stockpiles. Silos are primarily used to store fine materials and finished recycled aggregates, such as recycled sand and recycled stone. Their sealed structure prevents moisture and dust contamination, and they are equipped with unloading devices for easy access in subsequent production. Stockpiles are used to store raw construction waste and large finished products. A zoned stacking method is used, with isolation walls separating different types of materials to prevent cross-contamination. The stockpile floor is hardened with concrete and has a drainage slope to prevent rainwater erosion and material loss.

IV. Intelligent Control Module: The Core Technology for Enhancing System Efficiency

With the application of Industry 4.0 technology, the intelligent control module has become the "brain" of modern construction waste sorting systems. Through automated control and data monitoring, it achieves efficient and precise system operation, reduces labor costs, and improves sorting quality. This module mainly consists of a control system, a sensor network, and a data management platform.

1. Control System: Achieving Automated Operation

The control system uses a PLC (Programmable Logic Controller) as its core, combined with a touchscreen and a host computer to form a hierarchical control system. Operators set production parameters via the touchscreen, such as feeding speed, crushing particle size, and sorting accuracy. The PLC automatically controls the operating status of each piece of equipment based on these parameters, achieving coordinated operation of feeding, crushing, and sorting. When a system malfunction occurs, such as equipment overload or material blockage, the control system will automatically issue an alarm and stop the machine, while displaying the fault location and cause for rapid repair. Some high-end systems are also equipped with remote control functionality, allowing operators to remotely monitor the system's operating status via mobile phone or computer, achieving unattended production.

2. Sensor Network: Real-time Monitoring of Operating Status

The sensor network acts as the "sensory organ" of intelligent control. By installing sensors at key locations on various equipment, it collects production data in real time. Weight sensors monitor feed rate and finished product output to ensure stable production load; vibration sensors detect the vibration frequency of crushing and screening equipment to promptly identify equipment malfunctions; concentration sensors monitor water concentration during wastewater treatment and automatically adjust flocculant dosage; metal sensors detect residual metal in sorted materials to ensure sorting accuracy. This data is transmitted to the control system in real time, providing a basis for parameter adjustment and fault diagnosis.

3. Data Management Platform: Production Optimization

The data management platform uses cloud computing and big data analytics to aggregate, analyze, and store the production data collected by sensors. The platform can generate production reports, such as daily output, material recovery rate, and equipment failure rate, providing data support for enterprise production management. Simultaneously, by analyzing historical data, it optimizes production parameters, such as automatically adjusting the magnetic field strength or airflow speed of the sorting equipment based on the compositional differences of different batches of construction waste, thereby improving sorting efficiency. Furthermore, the platform also features equipment maintenance reminders, proactively alerting operators to perform maintenance based on equipment operating time and wear conditions, thus extending equipment lifespan.

The construction waste sorting system is a complex system with multiple modules working collaboratively. The pre-processing module provides qualified raw materials for sorting, the core sorting module achieves precise material separation, auxiliary modules ensure stable system operation, and the intelligent control module improves production efficiency and quality. These modules support each other and are closely integrated to jointly achieve the reduction, resource recovery, and harmless treatment of construction waste. With tightening environmental policies and the development of recycling technologies, future construction waste sorting systems will evolve towards greater intelligence, efficiency, and environmental friendliness. For example, the introduction of AI visual recognition technology will improve sorting accuracy, and the adoption of new energy power will reduce energy consumption, propelling the construction waste resource utilization industry towards a high-quality development stage.

Save Time! Get A Detailed Quotation Quickly.