Shredders, as a crucial component of solid waste treatment equipment, are widely used in recycling, municipal solid waste treatment, and industrial waste pretreatment. With global resource scarcity, increasingly stringent environmental regulations, and the development of green industrial chains, shredder technology has continuously advanced, evolving from simple early crushing equipment into modern equipment with diverse structures, intelligent control, and wide application scenarios. This article systematically describes the development and current status of shredder technology from the perspectives of technological evolution, equipment types, key technologies, industry applications, and future development trends.

The Development History of Shredder Technology

The origins of shredder technology can be traced back to the early days of industrialization. The earliest shredders were mostly simple single-rotor crushing devices, whose main function was to roughly tear larger materials for subsequent transportation or processing. These devices had low power, low output, and a limited range of applicable materials, only suitable for processing relatively soft wastes such as wood and paper.

With the rapid development of the metallurgical industry, machinery manufacturing, and urbanization, the composition of solid waste has become more diverse and complex, and traditional crushing equipment can no longer meet the processing needs. Therefore, starting in the second half of the 20th century, countries in Europe, America, and Japan successively developed more complex equipment such as dual-shaft shear shredders and four-shaft shredders, capable of handling mixed metals, waste household appliances, plastics, rubber, and other materials with higher shearing force and more stable operating performance.

Entering the 21st century, China's renewable resources industry rapidly rose, prompting a new surge in shredder technology development. Domestic enterprises, based on absorbing advanced foreign technologies, continuously improved equipment structure, enhanced blade material performance, and introduced automatic control systems, resulting in significant progress in the reliability, output, and intelligence of domestically produced shredders, gradually forming a complete product system.

Main Types and Technical Characteristics of Shredders

Based on different structural forms and working principles, modern shredders are mainly divided into the following categories:

1. Single-shaft Shredder

A single-shaft shredder consists of a rotor with blades and a loading pressure plate. The material is cut by the blades under the pressure of the plate. This type of equipment is characterized by high control precision, uniform output, and suitability for relatively homogeneous materials such as plastics, thin metal sheets, and wood. 1. **Simple Cutting Blade Structure and Easy Maintenance:** While its blade structure is simple and easy to maintain, its capacity is limited when processing mixed hard materials.

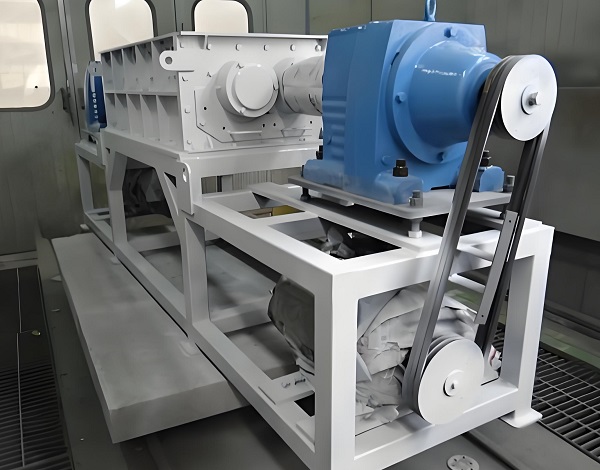

2. Twin-Shaft Shredder:

The twin-shaft shredder uses two meshing cutter shafts to tear and shear materials at low speed and high torque. It is suitable for a wide range of materials, including waste appliances, tires, metal drums, and household waste. The twin-shaft structure offers advantages such as less material jamming, lower noise, and relatively simple maintenance, making it the most widely used type of shredding equipment.

3. Four-Shaft Shredder:

The four-shaft shredder adds an auxiliary shaft to the twin-shaft structure, creating a circulating cutting process within the equipment. This results in more uniform output and more controllable particle size. It is commonly used for materials requiring strict particle size control, such as waste hard drives, refined electronic waste, and confidential documents, and is the mainstream equipment in the field of fine shredding.

4. Heavy-Duty Metal Shredder (Shredder Production Line)

Targeting heavy-duty materials such as scrapped automobiles, metal briquettes, and large scrap steel, heavy-duty shredders utilize high-strength, wear-resistant blades and high-power motors, supplemented by hydraulic feeding and intelligent control systems. This enables continuous, high-intensity operation, making it a core piece of equipment in the metal resource recycling industry.

Key Advances in Shredder Technology

As a mechanical equipment, the performance improvement of shredders mainly stems from advancements in the following key technologies:

1. Blade Materials and Manufacturing Technology

Blades are the core of shredder performance. Modern shredder blades widely utilize high-alloy tool steel, carburized steel, and chromium-molybdenum steel, improving hardness and wear resistance through heat treatment and quenching techniques. Some high-end equipment even uses powder metallurgy blades to enhance adaptability to high-hardness materials.

2. High-Torque Drive and Transmission System

Traditional belt drives are gradually being replaced by planetary reducers and high-torque motors and hydraulic motors, enabling shredders to handle high-strength metals, thick-walled plastics, and large structural components. Torque monitoring and overload protection technologies ensure more stable equipment operation. 3. Intelligent Control Technology

Intelligent functions such as PLC control, automatic reverse rotation, load adjustment, and foreign object detection significantly improve the automation level of the equipment. Some high-end shredders are equipped with remote monitoring systems that can record torque, current, and blade wear in real time, effectively reducing the failure rate.

4. Noise and Dust Control Technology

Environmental standards place higher demands on the operating environment of equipment. Shredders reduce their environmental impact and improve the overall environmental protection level of the factory through structural optimization, the installation of noise reduction covers, and dust removal systems.

Current Industry Applications of Shredders

With the development of the circular economy, shredders have become an indispensable key equipment in the resource recycling industry. Their main applications include:

1. Scrap Metal Recycling

Large quantities of scrap metal, such as dismantled cars, motorcycles, electrical appliance casings, and steel scraps, require pre-processing through shredders for sorting and smelting.

2. Solid Waste Treatment Industry

Complex solid wastes such as municipal solid waste, construction waste, and garden waste require shredding for volume reduction and homogenization, creating conditions for subsequent incineration, landfill, or resource utilization.

3. Waste Plastics and Rubber Industry

Materials such as plastic film, rigid plastic, and tires can be shredded to produce recyclable pellets, a crucial step in the recycled plastics industry chain.

4. Electronic Waste Treatment

Waste hard drives, circuit boards, small appliances, and other materials containing mixtures of metal and plastic require fine shredding to separate valuable components.

5. Specialized Fields

Including the destruction of confidential documents, pretreatment of medical waste, and safe disposal of hazardous waste, these fields have stricter requirements for particle size and safety.

Development Trends of Shredder Technology

With the deepening of industrial intelligence and sustainable development concepts, future shredder technology will exhibit the following trends:

1. Intelligent and Unmanned Operation

Future shredding equipment will increasingly possess functions such as automatic material identification, intelligent torque adjustment, and autonomous optimization of operating parameters. It may even be able to interface with production lines and ERP systems to achieve a high degree of automation.

2. High Efficiency and Energy Saving

By improving blade structure, optimizing the drive system, and using high-efficiency motors, energy consumption is significantly reduced, increasing output and overall equipment efficiency.

3. Green Environmental Protection and Enhanced Safety

Future shredders will place greater emphasis on noise reduction, explosion-proof, dust control, and safety protection systems to meet increasingly stringent environmental regulations and operational safety requirements.

4. Modularization and Flexibility

Modular design makes the equipment easier to maintain and upgrade, and allows for rapid adjustment of blade structure and operating parameters according to different materials, improving application flexibility.

The development of shredder technology is closely related to the needs of the global resource recycling industry. With the development of new materials, new technologies, and intelligent manufacturing, shredders will continue to evolve towards higher efficiency, intelligence, and greener operation, playing a more important role in solid waste treatment, resource recycling, and industrial production. Currently, domestic shredder technology has narrowed the gap with international advanced levels, but there is still room for improvement in high-end blade materials and intelligent control systems. In the future, with policy support and industrial innovation, China's shredder industry is expected to achieve breakthroughs and upgrades on a broader scale.

Save Time! Get A Detailed Quotation Quickly.