As a crucial technology for solid waste resource recovery, the twin-shaft shredder has become one of the most widely used shredding devices in modern waste pretreatment and resource recycling processes due to its strong processing capacity, wide applicability to materials, and stable operation. From the recycled metal industry to municipal solid waste treatment, from the rubber and plastics recycling industry to the dismantling and utilization of bulky waste, the twin-shaft shredder has demonstrated high adaptability and reliability in practical applications. Driven by the "dual-carbon goals," the circular economy, and the intelligent equipment manufacturing industry, twin-shaft shredder technology has undergone continuous iteration and updates, achieving significant progress in structural design, blade materials, transmission systems, and intelligent control. This article will systematically analyze the working principle, functional characteristics, structural advantages, industry applications, and development trends of the twin-shaft shredder to deeply explore its core value in the field of solid waste treatment.

A. Working Principle and Structural Features of the Twin-Shaft Shredder

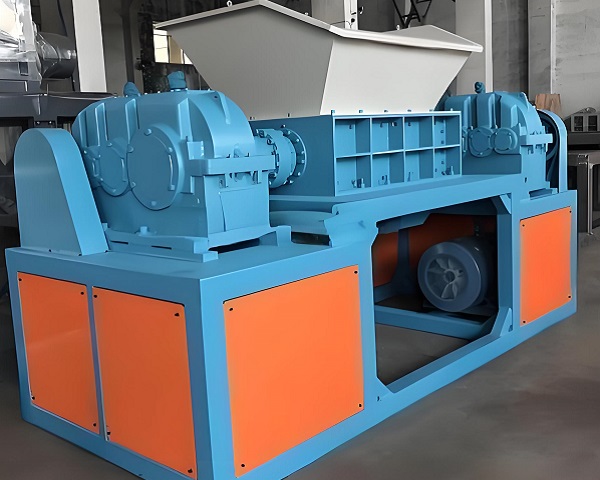

The core structure of the twin-shaft shredder consists of two parallel blade shafts rotating in opposite directions. The meshing blades create high-intensity shearing, tearing, and compressing effects. After entering the shredding chamber, materials are rapidly torn into smaller particles or flakes under the dual extrusion pressure and torsional load of the blades. Compared to single-shaft shredders, which primarily rely on cutting action, dual-shaft shredders employ a more aggressive and powerful shearing method, easily handling materials with complex compositions and irregular shapes. This working method determines that dual-shaft shredders are characterized by high torque, low speed, and strong crushing capacity.

Furthermore, the structure of a dual-shaft shredder typically includes a feeding device, blade system, drive system, machine support, discharge and conveying mechanism, and intelligent control module. With the development of hydraulic and electronic control technologies in recent years, many devices have incorporated functions such as automatic reverse rotation, overload protection, and multi-stage crushing, further improving the operational stability and safety of dual-shaft shredders.

B. Key Features of Twin-Shaft Shredders

Twin-shaft shredders possess the following typical features in terms of structural design and functional performance:

1. Powerful Shredding Capacity and Processing Efficiency

Twin-shaft shredders employ a dual-rotor linkage cutting structure, generating high torque at relatively low speeds. Therefore, they excel in processing large waste items, metallic waste, and hard materials such as thick-walled plastics. They can continuously and stably shred difficult-to-process materials, achieving high-throughput operation. In practical industrial applications, twin-shaft shredders commonly achieve processing capacities of several tons or even tens of tons per hour, providing a solid foundation for large-scale processing across multiple industries.

2. Wide Range of Applicable Materials

Twin-shaft shredders are suitable for almost all solid wastes, including waste household appliances, refrigerators, metal drums, scrap steel, end-of-life car shells, wood, plastics, rubber, fiberglass, packaging waste, furniture, waste paper, etc. This broad adaptability stems from the inherent advantages of the twin-shaft structure in shear strength and material gripping ability, making it widely used in fields such as renewable resource recycling, waste treatment, and hazardous waste pretreatment.

3. Stable Operation and Low Failure Rate

Due to its low-speed, high-torque operating mode, the twin-shaft shredder experiences slow blade wear, minimal mechanical impact, and a low failure rate. Its compact internal structure and stable power transmission mechanism allow for long-term, high-efficiency continuous operation. Furthermore, the equipment is typically equipped with automatic detection and protection modules, such as overload protection, automatic reverse rotation, and foreign object removal, further enhancing equipment safety.

4. Uniform Output and High Controllability

The twin-shaft shredder possesses excellent shredding and homogenization capabilities, breaking materials into uniformly sized flakes, which is beneficial for subsequent screening, conveying, and sorting. Some high-end models also feature a particle size control system, allowing adjustment of the final output specifications through blade replacement to meet different processing requirements.

5. Excellent Environmental Performance

Low noise and minimal dust are another significant characteristic of the twin-shaft shredder. Compared to high-speed cutting equipment, its low-speed design effectively reduces equipment noise and dust dispersion. In addition, most twin-shaft shredders are equipped with dust removal systems and enclosed structures, which effectively improve the working environment and enable the equipment to meet modern environmental protection production standards.

C. Core Advantages of Twin-Shaft Shredders

The advantages of twin-shaft shredders are reflected in the following aspects:

1. High-efficiency crushing and energy-saving characteristics

Twin-shaft shredders mostly operate at low speeds during the shredding process, which not only reduces energy consumption but also avoids overheating problems and accident risks caused by high-speed cutting. This energy-saving structure is particularly suitable for large-scale industrial production lines that operate continuously for long periods, and is one of the representatives of low-energy-consumption and high-efficiency equipment in the modern waste treatment industry.

2. Significant advantages in blade structure and materials

The blades of twin-shaft shredders are usually made of alloy steel, tool steel, or high-wear-resistant materials, and their hardness and wear resistance are improved through advanced heat treatment processes. This results in a longer blade life and suitability for long-term processing of complex and hard materials. Furthermore, the blade structure can be customized, allowing for the selection of different types of claw blades, hook blades, or assembled blades depending on the material, such as metal, plastic, or rubber, greatly improving the flexibility of the equipment.

3. Modular Design and Convenient Maintenance: Modern dual-shaft shredders generally adopt a modular structure design, allowing for quick disassembly and replacement of the machine body, cutter shaft, bearing housing, and support frame, making daily maintenance more convenient. Short maintenance cycles and minimal downtime ensure continuous production line operation. For manufacturing enterprises, this not only reduces maintenance costs but also extends equipment lifespan.

4. High Safety and Reliability: Dual-shaft shredders are typically equipped with comprehensive intelligent protection systems, including automatic reverse rotation, jam detection, current monitoring, automatic removal of small foreign objects, and fault alarms. In case of abnormal operation, the cutter shaft can be stopped or reversed immediately to prevent damage or accidents. This significantly improves equipment safety and greatly reduces the workload and risks for operators.

5. Enables Intelligent and Automated Operation: With the development of intelligent industrial equipment, more and more dual-shaft shredders are incorporating intelligent control systems, using PLCs, touch panels, and big data monitoring for parameter adjustment and operation management. Some high-end equipment even has remote monitoring, data recording, and real-time management functions, allowing seamless integration with smart factory systems.

D. Typical Application Areas of Twin-Shaft Shredders

Twin-shaft shredders are widely used in multiple industrial sectors:

Scrap metal recycling: Used for processing scrap steel, waste car shells, metal briquettes, etc.

Plastics recycling and rubber processing: Suitable for plastic buckets, tires, PE/PP, films, etc.

Municipal waste and hazardous waste treatment: Achieves volume reduction and harmless pretreatment of waste.

Bulk waste dismantling: Shredders furniture, home appliances, household waste, packaging materials, etc.

Electronic waste recycling: Shreds discarded home appliances, main unit casings, circuit boards, etc., providing a foundation for subsequent sorting.

They play an irreplaceable role in the circular economy system and have become key equipment for waste resource utilization and green development.

E. Future Development Trends

The future development of dual-shaft shredders will move towards higher efficiency, intelligence, greener operation, and larger scale:

1. Intelligent and remote control will become mainstream;

2. Equipment structures will become more modular and customized;

3. Energy-saving technologies and environmental protection systems will continue to be optimized;

4. Cutting material and drive systems will become more advanced;

5. Integrated production line solutions will become widespread.

With its advantages of high torque, low speed, wide applicability, and stable operation, the dual-shaft shredder has become one of the core equipment in the solid waste treatment industry. With the development of intelligent manufacturing and the environmental protection industry, the technological application boundaries of dual-shaft shredders will continue to expand, playing an even more important role in the green industrial chain and sustainable development strategies.

Save Time! Get A Detailed Quotation Quickly.