As a key piece of equipment in the field of solid waste treatment and resource recycling, the shredder's operating efficiency, stability, and shredding effect directly determine the processing capacity and economic benefits of the entire production line. However, many companies often only focus on the basic operation of the equipment during actual use, neglecting the technical principles, operation management, maintenance strategies, and matching issues of supporting systems behind the shredder's efficiency. While the performance of the equipment itself is important, the more crucial aspect is how to maximize its efficiency under specific application environments. This article systematically explores the path to maximizing shredder efficiency from multiple levels, including shredder selection, operation and debugging, tool management, intelligent control, production line collaboration, and safety maintenance and management systems.

A. Precise Selection: The Prerequisite for Efficiency

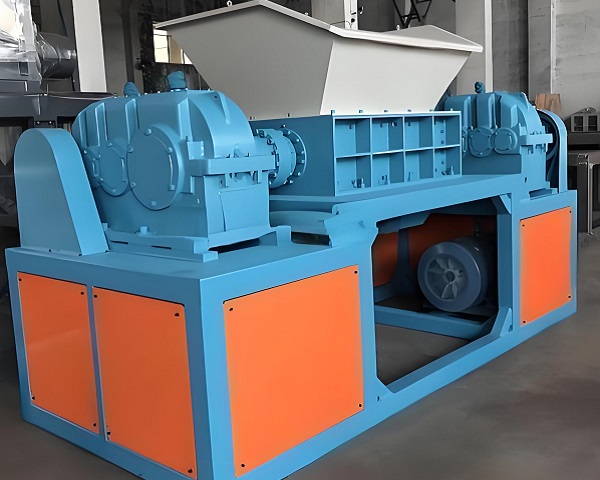

The core prerequisite for shredder efficiency is the precise matching of equipment with processing needs. Blindly selecting a shredder will directly lead to wasted capacity or overload operation. First, it's crucial to define the core parameters of the material to be processed: the material type (e.g., scrap metal, plastic, wood, household waste) determines the blade type selection for the shredder—high-hardness alloy blades are needed for metal materials, claw or toothed blades are recommended for plastics, and spiral blades are suitable for wood; the material size must match the feed inlet diameter, and pretreatment to remove oversized impurities is recommended to prevent jamming; the material moisture content should be controlled below 15%, as excessive moisture can cause material adhesion and reduce crushing efficiency. Second, select the equipment specifications based on capacity requirements. A 1600-type shredder (typically referring to a 1600mm feed inlet width) is suitable for medium-scale processing needs and requires a matching motor (55-75kW recommended) to ensure a balance between power output and crushing load. Simultaneously, pay attention to equipment configuration, prioritizing a twin-shaft shredder, which offers stronger shearing force, wider material adaptability, and a reverse function to effectively handle jamming issues and improve continuous operation capability.

B. Standardized Operation: Ensuring Real-Time Operational Efficiency

1. Feed Control and Operational Procedures

Normal feeding is crucial for ensuring efficiency; avoid overload and jamming caused by feeding large amounts of material at once. It is recommended to use a quantitative feeding device (such as a vibrating feeder) to control the feeding speed and single-feed volume, ensuring uniform material distribution in the crushing chamber and sufficient shearing by the blades. During operation, follow the principle of "start the machine before feeding, stop the machine before shutting it down." Before starting, run the machine unloaded for 3-5 minutes to check the blade rotation, lubrication system, and safety devices for proper functioning. During feeding, continuously monitor the equipment's operating status. If abnormal noises, increased vibration, or abnormally high current occur, immediately stop the machine and clean it to eliminate material jamming or hard impurities (such as metal blocks or stones). For sticky materials (such as wet plastics or rubber), add an appropriate amount of desiccant or dispersant during feeding to prevent material from entanglement with the blades.

2. Reasonable Setting of Discharge Particle Size

Adjust the discharge particle size according to subsequent processing requirements to avoid energy waste caused by over-crushing. The particle size of the shredder is controlled by adjusting the blade gap. If the gap is too large, the output particle size will be uneven, requiring secondary crushing; if the gap is too small, it will increase blade wear and motor load, reducing processing efficiency. It is recommended to set the optimal gap according to the material's intended use. For example, when shredding waste plastic for recycling and granulation, the gap should be controlled at 5-10mm to ensure both the quality of the recycled material and maintain high production capacity. At the same time, the output particle size should be checked regularly. If uneven or excessively large particle sizes are found, the gap should be adjusted or the blades replaced promptly.

C. Maintenance: The Core of Extended Lifespan and Stable Performance

1. Blade Maintenance The blades are the core component of the shredder, and their sharpness directly affects the crushing efficiency. The wear of the blades should be checked regularly. When the blade wear exceeds 2mm or chipping occurs, it should be sharpened or replaced promptly. During sharpening, the blade cutting angle must be consistent (usually 30-45°) to avoid affecting the shearing effect. When replacing blades, ensure they are securely installed with a uniform gap to prevent vibration during operation. In addition, select appropriate cutting tool materials based on material characteristics. Use Cr12MoV alloy cutting tools for hard materials and high-speed steel cutting tools for tough materials to extend tool life.

2. Lubrication and Cleaning Regularly lubricate the bearings, gears, and other transmission components of the equipment. Use suitable lubricating oil (such as heavy-duty gear oil) and add or change it periodically according to the instruction manual. Generally, change the lubricating oil every 500 hours of operation to ensure smooth operation of transmission components and reduce friction loss. Keep the equipment clean, promptly removing residual material from the crushing chamber, feed inlet, and discharge outlet to prevent material accumulation that could cause jamming or equipment corrosion. Regularly clean dust from the motor and radiator to ensure effective heat dissipation and prevent motor overheating and damage.

3. Replacement of Wear Parts Besides cutting tools, the equipment's liners, screens, and drive belts are all wear parts and require regular inspection and replacement. Liner wear increases the material crushing space, affecting crushing efficiency. It is recommended to check the liner every 1000 hours of operation and replace it promptly if wear is severe. Clogged screens cause poor discharge and require regular cleaning or replacement to avoid impacting production capacity. If the drive belt becomes loose or cracked, adjust the tension or replace it immediately to prevent insufficient power transmission.

D. Process Optimization: Improving Overall Processing System Efficiency

The efficiency of a shredder depends not only on the equipment itself but also on the pre- and post-processing steps. A pre-treatment process is needed at the front end to remove impurities (such as metal, glass, and stones) from the material to prevent damage to the blades and equipment. For large materials, pre-crushing with a shear or crusher can reduce the shredder's processing load. The back end needs appropriate discharge conveying and separation equipment, such as vibrating screens and magnetic separators, to promptly separate qualified materials from incompletely crushed materials. Unqualified materials are returned to the shredder for re-crushing, forming a closed-loop process and improving overall crushing efficiency. Simultaneously, optimize equipment layout, shorten material conveying distance, and reduce losses and time waste during conveying; rationally arrange production shifts according to capacity requirements to avoid equipment idling or overloading, and improve equipment utilization.

E. Safety Management: A Prerequisite for Continuous Operation

Safe operation is the foundation for maximizing efficiency, requiring the establishment of a comprehensive safety management system. Operators must undergo professional training, be familiar with equipment operating procedures and safety precautions, and strictly prohibit unauthorized operations (such as opening the crushing chamber during startup or manually cleaning materials); equipment must be equipped with overload protection, emergency stop buttons, and other safety devices, and their effectiveness must be checked regularly; warning signs should be set up at the work site to prevent unauthorized personnel from entering. At the same time, establish equipment operation logs to record startup time, processing volume, maintenance status, and other information to facilitate timely detection of equipment abnormalities, develop targeted maintenance plans, and ensure continuous and stable equipment operation.

Maximizing the efficiency of a shredder is a systematic project, requiring coordinated efforts from multiple aspects, from precise matching during the selection phase to standardized control of the operation process, routine maintenance, and overall optimization of the process system. By scientifically selecting equipment, standardizing operation, regularly maintaining and upgrading processes, we can improve the processing efficiency and output quality of shredders, extend equipment life, reduce operating costs, and maximize economic benefits and equipment efficiency.

Save Time! Get A Detailed Quotation Quickly.