In industrial sectors such as mining, building materials production, and road construction, crushing equipment is a core component of material processing, and its performance directly impacts production efficiency and product quality. The double-roll crusher, a long-established and continuously upgraded extrusion crushing equipment, has become the preferred solution for crushing medium-hardness materials due to its scientific structural design and flexible functional adaptability. With "precise particle control and high energy efficiency" as its core design concept, it solves the pain points of uneven particle size and high energy consumption of traditional crushing equipment through the collaborative operation of modular components, while also adapting to the production needs of various scenarios. This article will systematically analyze its technical advantages from the perspective of structural composition and core features, providing a reference for industry selection and application.

A. Structural Composition and Core Features of the Double-Roll Crusher

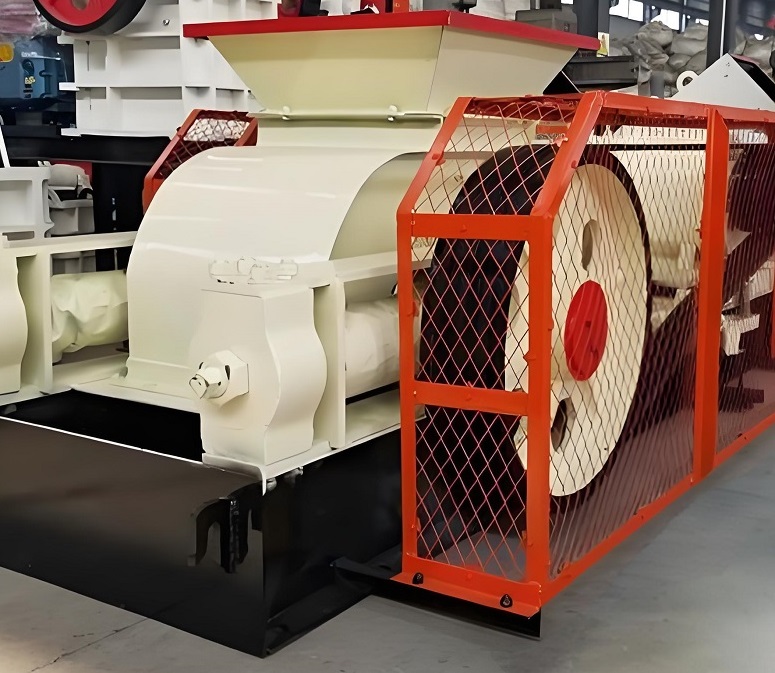

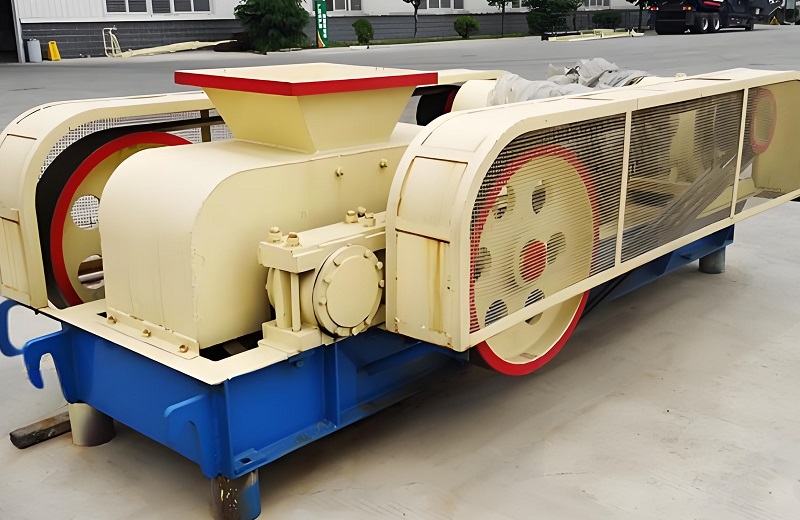

1. As a classic extrusion crushing equipment, the double-roll crusher's structural design revolves around the core requirements of "high-efficiency extrusion and precise particle control." It mainly consists of five core parts: the frame, roller assembly, transmission system, adjustment device, and safety protection device. These components work together to form a compact and stable crushing system.

2. The frame, serving as the load-bearing foundation of the equipment, adopts an integral welded or cast iron structure, possessing high strength and rigidity. The frame features a feed inlet at the top, a discharge channel at the bottom, and a maintenance door on the side, ensuring structural stability during high-intensity crushing operations and facilitating later maintenance. For large-scale equipment such as the 1600 model, the frame incorporates reinforcing ribs to disperse radial pressure generated during crushing, preventing deformation and extending the equipment's service life.

3. The roller assembly is the core working component of the roller crusher, consisting of two parallel cylindrical rollers. Depending on the crushing requirements, it can be divided into smooth rollers and toothed rollers. Smooth rollers have a smooth surface, suitable for medium and fine crushing and shaping operations, producing regularly shaped particles. Toothed rollers have evenly distributed toothed protrusions on their surface, suitable for coarse and medium crushing, effectively biting into lumpy materials and improving crushing efficiency. The rollers are made of high-strength alloy steel or wear-resistant cast iron, with surface hardening and welding treatments achieving a hardness of HRC55-60. They possess excellent wear resistance and can handle the crushing requirements of hard materials such as granite and basalt. Two roller shafts are fixed to the frame via bearing seats. Self-aligning roller bearings are used, providing good radial load capacity and automatic self-aligning function, effectively offsetting off-center loads generated during crushing and reducing equipment operating noise.

4. The transmission system adopts a "motor-reducer-coupling-roller shaft" transmission method, ensuring smooth and efficient power transmission. The motor is connected to the reducer via a V-belt or coupling. The reducer uses a hardened gear design, achieving a transmission efficiency of over 95%, converting the high-speed rotation of the motor into low-speed, high-torque rotation of the roller shaft to meet the power requirements of crushing operations. Some high-end equipment is also equipped with a variable frequency speed control system, which can flexibly adjust the roller shaft speed according to parameters such as material hardness and feed particle size, achieving precise control of crushing efficiency and product particle size.

5. The adjustment device is a key structure for achieving controllable product particle size, primarily controlling the output particle size by adjusting the gap between two rollers. There are two adjustment methods: manual and hydraulic. Manual adjustment uses a screw mechanism for fine-tuning the gap, suitable for small to medium-scale production. Hydraulic adjustment uses a hydraulic cylinder drive, enabling rapid gap adjustment and automatic compensation. In large-scale production, it effectively handles fluctuations in material hardness, ensuring the stability of the output particle size. The roller gap adjustment range is typically 1-50mm, meeting the diverse particle size requirements of different industries.

6. Safety protection devices ensure stable equipment operation, mainly including overload protection, dustproof sealing, and emergency braking modules. Overload protection is achieved through a torque limiter or hydraulic safety valve. When hard objects such as iron blocks are mixed in the material, the equipment will automatically stop or release pressure to prevent damage to core components such as rollers and reducers. The dustproof seal uses a combination of labyrinth seals and sealing felt to effectively prevent dust leakage during crushing, protecting the health of operators and preventing dust from wearing down precision components such as bearings. An emergency braking device can quickly cut off the power supply in case of equipment failure, ensuring the safety of equipment and personnel.

B. Core Advantages of Double Roll Crusher

1. High crushing efficiency and low energy consumption: Utilizing the compression crushing principle, two rollers rotate relative to each other, instantly crushing the material with minimal energy loss. Compared to jaw crushers and cone crushers, double roll crushers reduce unit energy consumption by 30%-50%, especially when processing materials with medium to low hardness, where crushing efficiency is significantly improved. For example, in crushing coal and limestone, a single unit can process 50-500 tons per hour, meeting the needs of large-scale production.

2. Uniform particle size and good particle shape: By precisely adjusting the roller gap, uniform particle size control can be achieved, with a product qualification rate of over 90%. The material particles crushed by the smooth roller type double roller crusher are cubic in shape, with a needle-like and flaky content of less than 5%. They can be directly used in subsequent production without additional shaping, making them particularly suitable for industries with high requirements for material particle shape, such as concrete aggregate and road construction.

3. Compact structure and small footprint: The core components are highly integrated, and the frame design is compact, reducing the footprint by 40%-60% compared to other crushing equipment with the same processing capacity. The equipment can be arranged as a single machine or in series with multiple machines, suitable for production scenarios with limited space, such as underground crushing and small-scale mineral processing plants, significantly reducing plant construction costs.

4. Stable operation and low maintenance costs: Key components are made of wear-resistant and impact-resistant materials, and the structural design is simple, with few vulnerable parts, mainly roller skins and bearings, which are easy and quick to replace. The roller skin features a flip-up design, boasting a service life of 8000-12000 hours. Replacement only requires 1-2 hours, significantly reducing equipment downtime for maintenance. Simultaneously, the equipment exhibits low vibration and noise during operation, demonstrating strong operational stability and an annual operating time exceeding 3000 hours. Maintenance costs are only 60%-70% of similar equipment.

5. Wide Applicability and High Flexibility: It can process various materials such as coal, limestone, gypsum, iron ore, and granite. It is suitable for a wide range of material moisture content, capable of crushing materials with a moisture content below 15% without prior drying. By changing different types of rollers (smooth rollers, toothed rollers) and adjusting the roller shaft gap, it can meet various crushing needs, including coarse, medium, and fine crushing. It is widely used in mining, building materials, chemical, coal, and road construction industries.

6. Excellent Environmental Performance: Equipped with a complete dustproof sealing system, dust emission concentrations are lower than national environmental standards (≤10mg/m³), effectively improving the working environment. Meanwhile, the equipment operates at a noise level below 85dB, far lower than that of jaw crushers and other similar equipment, meeting green production requirements. Some models can also be equipped with a dust suppression spray system to further reduce dust pollution and meet the production needs of areas with stringent environmental regulations.

The double roll crusher, through optimized design of five core components including the frame, roller assembly, and transmission system, constructs a compact, stable, precise, and controllable crushing system. Its high-strength load-bearing capacity, wear-resistant treatment, and flexible adjustment characteristics give the equipment significant advantages such as high efficiency, low energy consumption, uniform particle size, and convenient maintenance. Whether in terms of product particle shape control, energy cost reduction, environmental compliance, or adaptability to multiple materials, it demonstrates outstanding application value. As an ideal piece of equipment for small- to medium-scale production and space-constrained scenarios, the double roll crusher will continue to play a vital role in the green and efficient development of industries such as mining and building materials, and its technological upgrades will further expand its application boundaries.

Save Time! Get A Detailed Quotation Quickly.