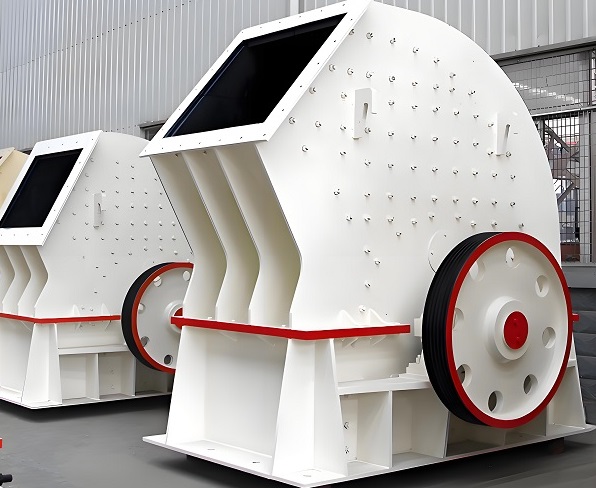

In the material crushing processes of industries such as mining, building materials, chemicals, and power, hammer crushers have become one of the mainstream equipment for processing medium- and low-hardness materials due to their simple structure and high crushing efficiency. They achieve rapid crushing by impacting, squeezing, and grinding materials with high-speed rotating hammers, and are widely used in the processing of materials such as limestone, coal, gypsum, and construction waste. This article will systematically outline the core functions of hammer crushers, deeply analyze their outstanding advantages compared to other crushing equipment, and explain their applicable scope in conjunction with actual application scenarios, providing a reference for industry equipment selection and production efficiency improvement.

A. Core Functions of Hammer Crusher

The core function of a hammer crusher is to crush blocky and granular materials to the particle size required for production. Its function can be subdivided into the following four main directions according to the application scenario and material characteristics:

1. Coarse and Medium Crushing of Materials

In most production lines, hammer crushers undertake the key task of coarse or medium crushing, especially suitable for processing medium- and low-hardness materials with a hardness ≤150MPa. For example, in the cement production industry, limestone, as the main raw material, needs to be crushed to a particle size of 20-50mm by a hammer crusher before being ground in a ball mill. In the coal industry, raw coal is crushed to 10-25mm by a hammer crusher to meet the feeding requirements of boiler combustion or coal washing processes. Compared to jaw crushers, hammer crushers can crush large materials (maximum feed size up to 1200mm) to the target particle size in one pass, reducing the number of crushing stages and simplifying the production process. Taking a building materials plant as an example, using a PCZ-1615 heavy hammer crusher to process limestone, the daily processing capacity reaches 1500-2000 tons. The crushed material has a uniform particle size, eliminating the need for additional intermediate crushing equipment and significantly reducing the investment cost of the production line.

2. Construction Waste Resource Utilization Crushing

With the advancement of policies promoting the resource utilization of construction waste, hammer crushers have become the preferred equipment for small and medium-sized construction waste treatment projects. It effectively processes mixtures of concrete blocks, waste bricks, ceramic fragments, and other materials. Through the impact of the hammers, it not only crushes the materials but also separates lightweight impurities (such as plastics and wood) from the aggregate, facilitating subsequent sorting. For example, in rural construction waste treatment stations, mobile hammer crushers can crush demolition waste on-site into 5-30mm recycled aggregate for use in paving rural roads or making non-fired bricks. The processing cost is only one-third of traditional landfill methods, while simultaneously achieving resource recycling.

3. High-Efficiency Crushing of Brittle Materials For brittle materials such as gypsum, shale, and coal gangue, the impact crushing principle of hammer crushers offers significant advantages. These materials easily fracture along internal fissures upon impact, are less prone to excessive pulverization, and exhibit high crushing efficiency. Taking gypsum processing as an example, after natural gypsum is crushed by a hammer crusher, the particle size is controlled at 30-50mm, and it can be directly fed into calcination equipment to produce building gypsum powder. The gypsum powder yield during the crushing process is less than 5%, far lower than the 10%-15% of jaw crushers, reducing material waste. A gypsum products factory uses a PC-1210 hammer crusher, processing 80-100 tons of gypsum raw materials per hour. The crushed material meets the requirements of the calcination process, and the product qualification rate is increased to over 98%.

4. Volume Reduction and Recycling of Industrial Waste In the chemical and power industries, hammer crushers are commonly used for volume reduction and valuable component recovery of industrial waste. For example, after being crushed by a hammer crusher, fly ash slag in the power industry can have its iron particles separated, and the scrap iron can be recovered through magnetic separation; after being crushed, phosphogypsum slag in the chemical industry is easier to treat and landfill, reducing the land area required. A thermal power plant uses a hammer crusher to process fly ash slag. After crushing, the slag volume is reduced by 40%-50%, which not only lowers landfill costs but also generates an additional 100,000-150,000 yuan in annual revenue through scrap iron recycling.

B.Key Advantages of Hammer Crusher

Compared to jaw crushers, impact crushers, and other similar equipment, hammer crushers have significant advantages in structural design, operating efficiency, and cost control. These advantages can be summarized in the following five points:

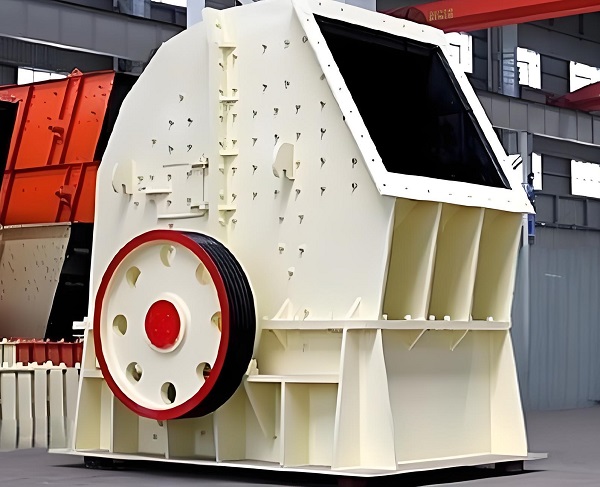

1. Simple Structure and Convenient Maintenance Hammer crushers are mainly composed of core components such as the casing, rotor, hammers, and screen plate. They lack complex transmission mechanisms, and the number of parts is only 60%-70% of that of impact crushers. Routine maintenance only requires periodically checking the wear of the hammers and the tightness of the bolts. When replacing vulnerable parts (such as hammers and screen plates), quick operation can be performed through the inspection door on the side of the equipment without disassembling the entire machine. Taking the PC series hammer crusher as an example, replacing a set of hammers takes only 2-3 hours, while replacing the hammer plates of a similar impact crusher takes 4-6 hours, improving maintenance efficiency by more than 50%. Furthermore, the simpler equipment structure reduces the failure rate. Statistics show that the mean time between failures (MTBF) of a hammer crusher can reach 3000-5000 hours, higher than the industry average.

2. High crushing efficiency and low energy consumption. The rotor speed of a hammer crusher can reach 750-1500 r/min, and the hammer linear velocity is as high as 20-40 m/s, enabling high-intensity impact on materials and resulting in crushing efficiency far exceeding that of traditional equipment. Experimental data shows that when processing limestone of the same hardness (80-100 MPa), the unit throughput of a hammer crusher can reach 1.2-1.5 tons/(kW·h), while that of a jaw crusher is only 0.8-1.0 tons/(kW·h), reducing energy consumption by 25%-30%. This advantage stems from its "one-hit crushing" working principle, which avoids repeated compression of materials within the crushing chamber, reducing energy loss. A comparative test by a coal company showed that using a hammer crusher to crush raw coal consumes 8-10 kWh per ton of material, saving 3-4 kWh compared to a jaw crusher, resulting in annual electricity savings exceeding 200,000 yuan.

3. Uniform Product Particle Size and Flexible Adjustment: By changing the screen plates with different apertures, the hammer crusher can precisely control the product particle size, with an adjustment range of 5-100mm, meeting the needs of various industries. For example, when processing construction waste, using a 20mm aperture screen plate can produce 5-20mm material that meets the standards for recycled aggregate; when processing coal, using a 15mm aperture screen plate can meet the particle size requirements for boiler combustion. Furthermore, the equipment's screen plates adopt a drawer-type design, making replacement convenient; screen plate replacement can be completed in just one hour, enabling rapid switching of product particle size. Furthermore, some new hammer crushers are equipped with hydraulic adjustment devices, which allow for real-time fine-tuning of product particle size by adjusting the gap between the hammers and the screen plate, eliminating the need to stop the machine to replace the screen plate and further enhancing production flexibility.

4. Low Equipment Investment and Operating Costs

From the perspective of equipment procurement costs, for the same processing capacity, the price of a hammer crusher is only 50%-70% of that of an impact crusher and 40%-60% of that of a cone crusher. Taking a daily limestone processing capacity of 1000 tons as an example, the procurement cost of a hammer crusher (PCZ-1512 model) is approximately 800,000-1,000,000 yuan, while an impact crusher (PF-1315 model) requires 1,500,000-1,800,000 yuan, resulting in a savings of over 40% in equipment investment. From an operating cost perspective, the wear parts (hammers and screen plates) of hammer crushers are inexpensive and have a long service life (high manganese steel hammers can last for 3,000-5,000 tons of material), with replacement costs only 30%-50% of those of impact crusher hammers. A small building materials factory's calculations show that the annual equipment maintenance and wear part replacement costs for hammer crushers are approximately 50,000-80,000 yuan, far lower than the 120,000-150,000 yuan for impact crushers.

5. Strong adaptability and wide application range: Hammer crushers can process a variety of materials, including limestone, coal, gypsum, construction waste, and coal gangue, and are highly adaptable to material moisture content (allowing a moisture content ≤15%), eliminating the need for additional drying equipment. For example, when processing wet coal during the rainy season, hammer crushers are less prone to material blockage, while jaw crushers are prone to material adhesion at the feed inlet, requiring frequent cleaning and affecting production efficiency. Furthermore, hammer crushers offer flexible feeding methods, accepting belt conveyors, vibrating feeders, and other options to adapt to different production line layouts. Whether in a stationary production line or a mobile crushing plant, hammer crushers can be easily integrated to meet the crushing needs of various industries, including mining, building materials, and municipal engineering.

Despite the significant advantages of hammer crushers, their application limitations must be considered: First, they are not suitable for processing materials with a hardness >150MPa (such as granite and basalt), as this will lead to severe hammer wear and shorten service life. Second, when processing sticky materials with a moisture content >15%, a dehumidification device is required to prevent material adhesion to the screen plate and subsequent blockage. Third, when processing materials containing a high amount of metallic impurities, an iron removal device must be installed at the feed inlet to prevent damage to the hammers and rotor.

In practical operation, the following points should be noted: First, strictly control the feed particle size to prevent oversized materials from entering the crushing chamber and thus preventing equipment overload; second, regularly check the wear of the hammers. When the wear exceeds 1/3 of the original size, replace them promptly or flip them over to ensure crushing efficiency; third, maintain the normal operation of the equipment's lubrication system and add lubricating oil regularly to prevent bearing overheating and damage.

Hammer crushers, with their advantages of simple structure, high efficiency, low cost, and strong adaptability, occupy an important position in the crushing of medium and low hardness materials, especially in small and medium-sized production lines, construction waste resource utilization, and industrial waste treatment, demonstrating irreplaceable value. With technological upgrades, new hammer crushers (such as heavy hammer crushers and reversible hammer crushers) are continuously improving in terms of processing capacity, particle size control accuracy, and environmental performance, further expanding their application scope. In the future, combined with intelligent technology, hammer crushers will achieve real-time monitoring of operating parameters and automatic fault warnings, promoting the development of crushing equipment towards high efficiency, intelligence, and greenness, providing strong support for improving production efficiency and sustainable development in various industries.

Save Time! Get A Detailed Quotation Quickly.