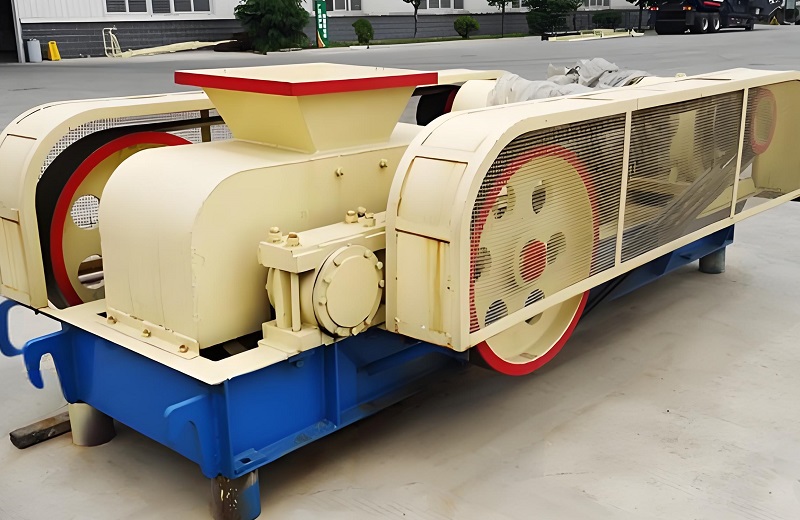

In the material processing stage of industrial production, the adaptability and comprehensive performance of crushing equipment directly affect production efficiency, product quality, and environmental compliance. As a compression crushing equipment that has undergone long-term technological iteration, the double roll crusher has been deeply integrated into multiple core industries such as mining, building materials, coal, and chemicals, thanks to its flexible functional design and outstanding application advantages. It not only adapts to the crushing needs of materials with different hardness and moisture content, but also solves many pain points of traditional crushing equipment through precise particle control and high efficiency with low consumption. This article will systematically review its core application scenarios and deeply analyze its comprehensive advantages, providing practical reference for industry selection and efficient production.

A. Core Application Scenarios of Double Roll Crusher

1. Mining Industry: The Mainstay for Multi-Material Crushing

In the mining field, the double roll crusher, with its strong wear resistance and flexible crushing ratio, has become the core pre-processing equipment for various minerals such as iron ore, limestone, granite, and basalt. Designed for open-pit and underground operations in small and medium-sized mines, the equipment's compact design adapts to confined spaces, making it particularly suitable for underground crushing plant layouts. It eliminates the need for large-scale plant excavation, reducing infrastructure costs. In iron ore crushing, a toothed roller crusher is used for coarse crushing, effectively absorbing lumpy ore (feed size up to 300mm). The crushed material has a uniform particle size (≤50mm) and can be directly conveyed to a ball mill for grinding, increasing crushing efficiency by more than 20% compared to traditional jaw crushers. When processing medium- to low-hardness ores such as limestone, the smooth roller crusher integrates medium and fine crushing, producing a product with a needle-like and flaky content of less than 5%, meeting the stringent particle size requirements of subsequent flotation and magnetic separation processes. Furthermore, the equipment boasts excellent dustproof sealing performance, controlling dust emission concentration below 10mg/m³ in dust-free production in metal mines, complying with mine environmental protection standards.

2. Building Materials Manufacturing Industry: A Superior Choice for Aggregate Shaping

In the building materials industry, double-roll crushers are key equipment in the production of concrete aggregates, cement raw materials, gypsum powder, and other products. In commercial concrete mixing plants, their outstanding advantage lies in their particle shaping capability—the aggregates crushed by a smooth-roll double-roll crusher are cubic in shape with a reasonable gradation. This can replace traditional impact crushers for aggregate refining, increasing concrete strength by 15%-20%. They are widely used in high-rise buildings, bridge projects, and other projects with stringent aggregate quality requirements. In cement production, double-roll crushers are used for medium crushing of raw materials such as limestone, clay, and iron ore. The feed particle size is ≤200mm, and the output particle size can be precisely controlled within 1-20mm, meeting the feeding requirements of cement rotary kilns. Furthermore, their unit energy consumption is only 60% of that of a cone crusher, significantly reducing the energy costs of cement production. In the gypsum board production sector, this equipment can process wet gypsum raw materials with a moisture content of 10%-15%, preventing material adhesion and blockage. The crushed gypsum powder has a uniform particle size (≤5mm), directly adaptable to subsequent calcination and molding processes, improving the continuity of gypsum board production.

3. Coal Industry: Core Equipment for High-Efficiency Desulfurization and Grading Crushing The coal industry is a traditional advantageous application area for double-roll crushers, especially suitable for crushing and desulfurization pretreatment of thermal coal and coking coal. In underground coal mines and surface coal preparation plants, toothed roller crushers can achieve integrated coarse and medium crushing of coal. The feed particle size is ≤400mm, and the output particle size can be adjusted according to boiler combustion requirements (5-50mm). During the crushing process, it can effectively separate sulfides such as pyrite from the coal, achieving a desulfurization efficiency of 30%-40%, reducing sulfur dioxide emissions from coal-fired power generation. For easily agglomerated materials such as lignite, the equipment features an anti-sticking roller surface design, coupled with a high-frequency vibration cleaning device, to prevent material from clumping on the roller surface and ensure continuous operation. In briquette production, the double-roll crusher can crush raw coal to a suitable particle size of 3-10mm, and the crushed coal has a reasonable particle size distribution, which can improve the briquette forming rate and compressive strength, and increase the briquette combustion efficiency by more than 10%.

4. Chemical and Metallurgical Industries: Precision Solutions for Fine Crushing The chemical and metallurgical industries have extremely high requirements for the precision and purity of material crushing. The double-roll crusher, with its high adjustment precision and low pollution, has become an ideal equipment for crushing chemical raw materials and metallurgical auxiliary materials. In the chemical industry, when processing corrosive materials such as calcium carbide, caustic soda, and fertilizer raw materials, the rollers of the equipment are made of corrosion-resistant alloy steel with anti-corrosion treatment to prevent equipment damage caused by material corrosion. When crushing fertilizer raw materials such as phosphate rock and potassium feldspar, the output particle size can be precisely controlled at 1-5mm, meeting the fineness requirements of fertilizer granulation processes, and the crushing process is dust-free, ensuring the cleanliness of chemical production. In the metallurgical industry, for the recycling of industrial waste such as steel slag and slag, the double-roll crusher can crush blocky waste (≤250mm) to ≤20mm. The crushed waste particles are uniform and can be used as cement admixtures or road base aggregates, realizing the resource utilization of solid waste. When processing metallurgical coke, the equipment adopts a low-speed, high-torque design to avoid excessive crushing of coke and loss of powder, and the coke powder recovery rate is 15%-20% higher than that of traditional crushers.

5. Road Construction Industry: High-Efficiency Processing Equipment for Subgrade Materials

In road construction, double-roll crushers are mainly used for crushing and processing asphalt mixtures and subgrade fillers. In highway and railway subgrade construction, a large amount of graded crushed stone (particle size 5-31.5mm) is required. Double-roll crushers can achieve continuous production of crushed stone of different particle sizes by adjusting the roller gap, resulting in a product gradation pass rate of over 95% and regular particle shape, which improves the compaction and bearing capacity of the subgrade. When processing recycled asphalt pavement, the equipment adopts a flexible crushing principle, avoiding asphalt aging and failure in the recycled material. The crushed recycled aggregate can be directly used in asphalt mixture mixing, achieving a recycling rate of over 80%, which aligns with the green and circular concept of road construction. Furthermore, the equipment is highly mobile (can be combined with a mobile crushing station), suitable for on-site crushing operations at road construction sites, reducing raw material transportation costs and improving construction efficiency, especially suitable for road construction projects in remote areas.

B. Comprehensive Advantages of Double Roll Crusher

1. Wide Material Adaptability and Flexible Crushing Functions

The core advantage of the double roll crusher lies in its wide adaptability to materials of different properties. It can handle various materials with hardness ranging from soft (such as coal and gypsum) to medium-hard (such as limestone and iron ore), with a moisture content adaptability range of 0%-15%, eliminating the need for pre-drying treatment and solving the pain point of traditional crushers being prone to clogging with wet and sticky materials. By changing different types of rollers (smooth rollers, toothed rollers, grooved rollers), it can achieve multiple functions such as coarse crushing, medium crushing, fine crushing, and shaping: toothed roller models are suitable for coarse crushing of large materials with strong biting ability; smooth roller models are suitable for medium and fine crushing and particle shaping, producing excellent product shapes; grooved roller models are suitable for crushing sticky materials with significant anti-sticking effects. This flexible function switching allows the equipment to meet the differentiated needs of multiple industries such as mining, building materials, and coal. One machine can replace multiple crushing equipment, reducing the equipment investment cost for enterprises.

2. High Efficiency and Low Consumption, Significant Production Benefits

Compared to traditional equipment such as jaw crushers and cone crushers, the double-roll crusher uses a compression crushing principle. Material is instantly crushed under pressure between two rollers, resulting in low energy loss. Unit energy consumption is only 1.5-3.0 kWh/t, a 30%-50% reduction compared to jaw crushers. In large-scale production, a single unit can process 50-500 tons per hour, meeting the continuous production needs of small and medium-sized enterprises. With a variable frequency speed control system, the roller speed can be adjusted in real time according to the feed rate and material hardness, further optimizing the balance between energy consumption and efficiency. Taking a limestone aggregate production line with an annual output of 1 million tons as an example, replacing a jaw crusher with a double-roll crusher can save approximately 800,000 yuan in electricity costs annually, extend equipment operating time to over 3,000 hours, and significantly improve production efficiency.

3. Excellent Product Quality and Low Subsequent Processing Costs

The double-roll crusher achieves precise control over the output particle size through accurate adjustment of the roller gap (adjustment range 1-50mm). The product boasts high particle size uniformity, with a pass rate exceeding 90%, eliminating the need for secondary screening equipment. The material crushed by the smooth roller crusher is cubic in shape, with a needle-like/flaky content of less than 5%, making it suitable for direct use as finished aggregate. This is particularly applicable to fields requiring precise particle shape, such as concrete and road construction, avoiding the additional costs associated with shaping processes required by traditional crushers. In industries like coal and chemicals, uniform particle size improves subsequent combustion and reaction efficiency. For example, crushed coal burns more completely, increasing thermal efficiency by over 10%; uniform particle size in chemical raw materials ensures consistent reaction rates and improves product purity.

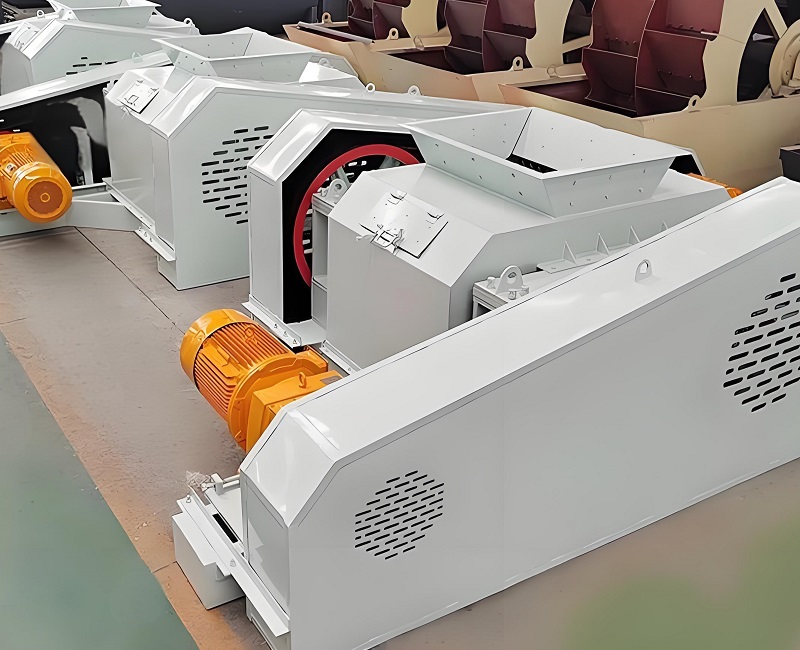

4. Compact Structure and Low Maintenance Costs: The equipment adopts a modular design with high integration of core components and a compact frame structure. Its footprint is reduced by 40%-60% compared to jaw crushers with the same processing capacity, making it suitable for production scenarios with limited space, such as underground crushing and small processing plants, thus reducing plant construction and equipment layout costs. In terms of maintenance, only a few vulnerable parts such as rollers and bearings are susceptible to wear. The rollers feature a flip-up design and a service life of 8,000-12,000 hours, requiring only 1-2 hours for replacement. Key components such as bearings and reducers adopt standardized designs, facilitating spare parts procurement and reducing maintenance costs to only 60%-70% of similar equipment. Furthermore, the equipment operates with low vibration (vibration acceleration ≤0.5g) and low noise (≤85dB), reducing damage to plant structures, lowering occupational health risks for operators, and further reducing hidden costs for enterprises.

5. Outstanding Environmental Performance, Meeting Green Production Requirements

The double-roll crusher is equipped with a complete dustproof sealing system, employing a labyrinth seal and sealing felt combination structure, coupled with a spray dust suppression device, which effectively controls dust leakage during the crushing process. Dust emission concentrations are far below national environmental standards (≤10mg/m³), meeting the environmental governance requirements of industries such as mining and building materials. The equipment operates without impact noise and has low energy consumption, reducing greenhouse gas emissions such as carbon dioxide, complying with the "dual carbon" policy requirements. In the field of solid waste resource utilization, such as the crushing and treatment of industrial waste slag like steel slag and coal gangue, the equipment can achieve waste reduction, harmlessness, and resource recovery, helping enterprises build a green circular production model and enhancing their environmental image and market competitiveness.

The double-roll crusher, with its multi-industry adaptability and multi-dimensional advantages, has become the preferred equipment in the industrial crushing field. Its applications cover key scenarios such as mining, building materials production, and coal processing, meeting the differentiated needs of coarse crushing, medium and fine crushing, and particle shaping, and is also suitable for handling special materials such as wet, sticky, and corrosive materials. In terms of overall advantages, the equipment boasts wide material adaptability, high efficiency and low consumption, superior product quality, low operation and maintenance costs, and outstanding environmental performance. This reduces equipment investment and operating costs for enterprises while also contributing to green production. As the industrial sector increasingly demands higher efficiency and environmental protection, double-roll crushers will further expand their application boundaries through technological upgrades, providing stable support for high-quality development across various industries.

Save Time! Get A Detailed Quotation Quickly.