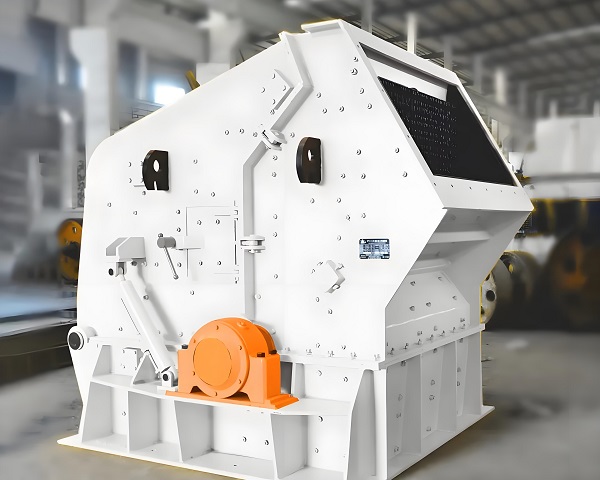

In industries such as mining, building materials processing, and construction waste recycling, impact crushers have become core equipment for crushing operations due to their unique structural design and superior performance. Their structural design directly determines crushing efficiency, finished product quality, and operational stability, while their application advantages adapt to diverse production needs. This article focuses on the core structure of the impact crusher, dissecting its structural design highlights from the rotor, impact frame, transmission system to auxiliary systems, and then analyzing its core advantages such as high-efficiency crushing, high-quality finished products, and convenient maintenance. Through systematic analysis, it provides professional reference for industry practitioners in selection, operation, and application, helping to fully realize the value of the equipment and adapt to the needs of green and efficient production development.

I. Characteristics of the Core Structure of the Impact Crusher

1. Rotor Mechanism: The Core Carrier of High-Energy Crushing

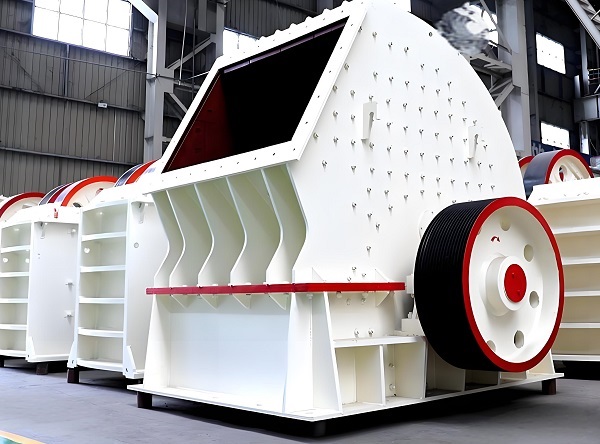

The rotor, as the power output core of the impact crusher, adopts an "integral cast steel frame + modular hammer installation" structural design, possessing high strength and high stability. The rotor shaft is made of 40CrNiMo alloy steel, which, after quenching and tempering, achieves a hardness of HRC30-35, exhibiting excellent bending and fatigue resistance, and can withstand impact loads during high-speed rotation. The hammer plates are installed with a circumferentially even distribution, secured to the rotor disc with high-strength bolts and equipped with anti-loosening washers to prevent them from falling off during high-speed vibration. A single rotor can accommodate 4-8 sets of hammer plates to adapt to different crushing needs. The rotor speed is designed for 800-1200 r/min, and combined with optimized hammer weight distribution, it generates a powerful inertial impact force, ensuring that materials entering the crushing chamber are instantly crushed. Wear-resistant guard plates are installed on the rotor disc edges to reduce wear on the rotor body.

2. Impact Frame and Crushing Chamber: Key Structures for Multi-Stage Crushing

The impact frame adopts an adjustable arc-shaped structure, consisting of impact plates, adjusting screws, and hydraulic cylinders. Precise gap adjustment is achieved via screw or hydraulic drive, with an adjustment range of 10-50 mm, flexibly adaptable to the required output particle size. The crushing chamber has a "V"-shaped design, forming a gradual crushing space between the impact plates and the rotor. After entering, the material undergoes a multi-stage crushing process of "impact-rebound-re-impact," ensuring thorough crushing. The impact plate is welded with a wear-resistant alloy layer, 10-15mm thick, providing excellent impact and wear resistance. Its segmented installation structure allows for individual replacement after localized wear, reducing maintenance costs. Some large equipment (such as the 1600 model) is equipped with a multi-cavity impact frame, featuring primary and secondary impact plates to achieve integrated coarse and fine crushing operations, improving crushing efficiency.

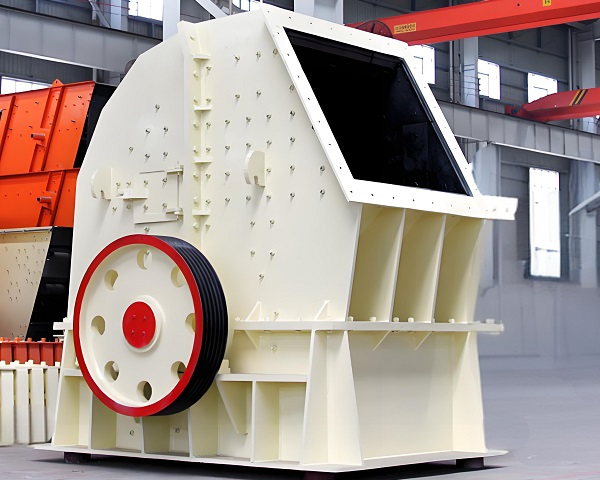

3. Transmission System: Ensuring Efficient Power Transmission The transmission system adopts a combined structure of "motor + coupling/pulley + gearbox," offering two transmission modes to adapt to different scenarios: a hard connection (coupling) provides high transmission efficiency (≥95%) and low power loss, suitable for stationary crushing plants; the belt drive has a buffer and shock absorption function, preventing motor damage under overload, suitable for mobile crushing equipment. The motor is a Y-series three-phase asynchronous motor with an IP54 protection rating and F-class insulation, capable of long-term operation under harsh conditions. The pulleys are made of gray cast iron and dynamically balanced for high rotational accuracy. The belts are either V-belts or synchronous belts, and tension can be flexibly adjusted by changing the position of the motor base to ensure smooth transmission.

4. Auxiliary System: Supporting Stable Operation

The lubrication system adopts a centralized oil supply design, equipped with a gear pump, oil tank, filter, etc., enabling automatic lubrication of critical components such as rotor bearings and transmission gears. 46# anti-wear hydraulic oil is used to ensure smooth component operation. The cooling system reduces bearing temperature through air or water cooling to prevent high-temperature aging. The air-cooling system is equipped with a cooling fan, while the water-cooling system has cooling water piping, allowing for flexible switching according to ambient temperature. The electrical control system integrates overload protection, emergency stop button, and operation monitoring functions. Equipped with a PLC controller, it can display real-time data such as motor current and bearing temperature, automatically stopping and alarming in case of abnormalities, improving operational safety.

II. Core Application Advantages of Impact Crusher

1. High Crushing Efficiency and Strong Processing Capacity

Thanks to the working principle of "impact crushing + multi-stage impact," the impact crusher's crushing efficiency far exceeds that of traditional jaw crushers, making it particularly suitable for crushing medium-to-low hardness materials (compressive strength ≤350MPa). Taking the 1600-type impact crusher as an example, its rated processing capacity can reach 150-300t/h, which is 30%-50% higher than that of a jaw crusher of the same specification. Its crushing chamber has no dead zone design, ensuring strong material throughput and preventing clogging. Furthermore, the feed particle size can reach 300-500mm, eliminating the need for complex pretreatment, significantly shortening the production process and improving overall operating efficiency.

2. Excellent Finished Particle Size and Reasonable Grading

By adjusting the gap between the impact frames and the rotor speed, the impact crusher can precisely control the output particle size, resulting in uniform finished particle size, low needle-like and flaky content (≤10%), and a reasonable gradation, meeting industry standards for construction sand and aggregates. During the crushing process, materials collide with each other, creating a "stone-on-stone" crushing effect. The finished particles are rounded with high compressive strength and can be directly used in concrete mixing, road paving, and other applications. Furthermore, the equipment supports multi-stage crushing adjustments, producing finished products of different specifications (e.g., 5-10mm, 10-20mm) to meet diverse application needs.

3. Compact Structure, Convenient Installation and Maintenance The impact crusher adopts an integrated frame design, resulting in a compact structure and small footprint. Compared to traditional crushing equipment, it saves 20%-30% of installation space, facilitating deployment in confined spaces or mobile crushing stations. Core components (such as hammers and impact plates) use a modular installation method, making disassembly and replacement convenient. Replacing a single hammer only takes 1-2 hours, significantly reducing maintenance time. The equipment operates with low vibration (vibration speed ≤4.5mm/s), requiring relatively low foundation requirements, reducing foundation construction investment and lowering initial investment costs.

4. Wide Adaptability and Strong Compatibility: The impact crusher can process a variety of materials, including limestone, granite, shale, and concrete waste. Whether crushing natural ore or recycling construction waste, it maintains stable performance. Its core components are made of wear-resistant materials; the hammers are made of Cr12MoV alloy or high-manganese steel, and the impact plates are equipped with wear-resistant liners, adapting to the crushing needs of highly abrasive materials. The equipment has excellent overload resistance; through the buffering effect of belt drive or hydraulic overload protection devices, it can effectively handle small amounts of hard impurities mixed in with the material, preventing equipment damage and improving operational stability.

5. Low Energy Consumption and Outstanding Environmental Performance: The impact crusher's crushing process relies on the inertial impact force of the rotor, requiring no additional pressure. Unit energy consumption is low, saving 20%-40% compared to traditional crushers. The equipment is equipped with a sealed crushing chamber and dust collection interface, effectively reducing dust leakage. Combined with a spray dust suppression system, dust emission concentration can be controlled below 50mg/m³, meeting environmental standards. The motor adopts an energy-saving design with a high power factor and an operating efficiency of ≥90%, further reducing energy costs and achieving green production.

With its unique structural design and significant application advantages, the impact crusher has become a core piece of equipment in industries such as mining, building materials processing, and construction waste recycling. Its high-energy rotor, adjustable impact frame, and efficient transmission system provide a solid guarantee for crushing efficiency and finished product quality; while its advantages such as high efficiency and energy saving, excellent particle size distribution, and convenient maintenance give it a strong competitive edge in the market. As the industry's requirements for finished product quality and environmental protection continue to rise, the impact crusher will further strengthen its advantages through technological upgrades (such as intelligent control and optimized wear-resistant materials), providing strong support for the high-quality development of the industry.

Save Time! Get A Detailed Quotation Quickly.