In the crushing process of industries such as mining, building materials, coal, and chemical, the double roll crusher (also known as the twin roll crusher) is a basic equipment with a long history and wide application. It uses two parallel arranged crushing rollers as the core working components, generating squeezing and shearing forces through the relative rotation of the rollers, to achieve crushing and processing of medium and low hardness materials. Compared to the multi-stage crushing structure of multi roll crushers, double roll crushers have the core features of "simplified structure and convenient operation", and demonstrate irreplaceable value in small and medium-sized production lines, mobile crushing scenarios, and operations that require relatively stable crushing particle size. An in-depth analysis of the characteristics and advantages of double roll crushers is of great practical guidance significance for enterprises to make reasonable selections, reduce production energy consumption, and improve operational efficiency.

A. Core features of double roll crusher

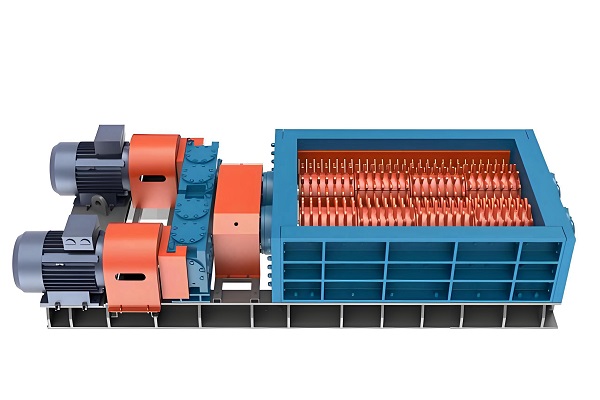

The characteristics of the double roll crusher stem from its "one fixed and one active" double roll core structure. This concise design has formed distinct features in crushing mechanism, operation and maintenance, and operational stability, which can be summarized into the following six aspects.

1. Clear crushing mechanism and intuitive particle size control

The crushing process of a double roll crusher relies entirely on the gap and relative rotational motion between two parallel rollers. After entering the crushing chamber formed by the two rollers, the material is continuously squeezed, ground, and sheared, and ultimately crushed to a particle size equivalent to the gap between the rollers. This control method of "gap determines particle size" is intuitive and reliable. Operators can accurately control the particle size of the discharged material by adjusting the position of the movable roller. The adjustment range is usually 1-50mm, which meets the needs of most medium and fine crushing. Unlike the graded crushing of multi roll crushers, the single-stage crushing mode of double roll crushers has a relatively small crushing ratio (usually 3-8), but for low to medium hardness materials such as limestone, coal gangue, shale, etc., it can fully achieve "one-time crushing compliance", avoiding the complex process problems caused by multi-stage crushing, and is particularly suitable for production lines that require high crushing efficiency.

2. Flexible adaptation of roller surface, catering to diverse needs

According to the physical characteristics of different materials, the double roll crusher can be equipped with multiple roller surface forms to achieve the effect of "one machine adapted to multiple materials". For brittle materials such as coal and coke, smooth rollers are often used to quickly crush them while reducing material adhesion through extrusion force; For materials with slightly higher hardness such as ores and rocks, toothed rollers or grooved rollers are used to improve crushing efficiency through the shearing effect of teeth and prevent material slippage on the roller surface; For viscous materials such as gypsum and bentonite, corrugated rollers can enhance the material grasping ability and avoid blockage of the crushing chamber. In addition, the material of the roller surface can be customized according to wear requirements. High manganese steel roller surface can be used as a common material to meet the needs. For scenarios with high wear resistance requirements such as quartz sand, roller surfaces coated with wear-resistant alloy or tungsten carbide can be used, and the service life can be extended to 2-3 times that of ordinary roller surfaces, greatly reducing the cost of replacing vulnerable parts.

Some small double roll crushers also adopt a detachable roller sleeve design, and operators can replace the roller sleeve with simple tools. The replacement time is usually controlled within 4 hours, which is more convenient than repairing the entire roller body and further improves the adaptability of the equipment to the production of multiple types of materials.

3. Simplified and compact structure, low operating threshold

The core structure of the double roll crusher only includes the main frame, double roll components, transmission system, regulating device, and lubrication system, without complex multi-level linkage mechanisms, and the overall size of the equipment is compact. Taking a small double roll crusher with a processing capacity of 10t/h as an example, it usually occupies an area of no more than 2 square meters and weighs only 1-2 tons. It is not only convenient for workshop layout, but also can be combined with a mobile chassis to form a mobile crushing equipment, meeting the needs of field operations such as mining and road construction. In terms of operation, the equipment adopts a simplified control mode of "one click start stop+manual adjustment". The feeding amount is manually adjusted by the feeder, and the gap between the rollers is adjusted by gaskets or manual hydraulic devices, without the need for professional automation operation skills. Ordinary workers can start work after simple training, which is particularly suitable for small and medium-sized enterprises and production scenarios where technical personnel are relatively scarce.

Although some upgraded models are equipped with basic overload alarm devices, the overall control logic is simple and the equipment failure rate is low, avoiding maintenance difficulties caused by complex control systems and meeting the actual needs of grassroots production.

4. Low consumption and stable operation, with low job noise

The roller speed of a double roll crusher is usually controlled between 50-100r/min, which is a low-speed operating equipment. Compared to impact crushers (with speeds mostly above 1000r/min), its motor power requirement is lower. Under the same processing capacity, the motor power of the double roll crusher is only 60% -70% of that of the jaw crusher, and the energy consumption per unit product can be reduced by 20% -30%. At the same time, low-speed operation significantly reduces the vibration amplitude of the equipment, usually controlled within 1.5mm. Coupled with the buffering effect of the rigid frame, the equipment has extremely high stability and can achieve 24-hour continuous operation. In terms of noise control, the crushing process of the double roll crusher is static compression, without high-frequency noise generated by severe impact. Coupled with the enclosed design of the casing, the operating noise can be controlled below 85 decibels, far lower than the 100 decibels or more of the impact crusher. No additional noise reduction equipment is required to meet the environmental protection requirements of the workshop.

For example, in a coal mine washing workshop, when multiple double roll crushers are running simultaneously, the overall noise level of the workshop can still be maintained at around 80 decibels, and operators can work normally without wearing professional sound insulation equipment, greatly improving the working environment.

5. Strong adaptability to feeding and reliable anti blocking design

The crushing chamber of the double roll crusher adopts a design of "wide feed inlet+gradual gap". The width of the feed inlet is usually 1.2-1.5 times the diameter of the rollers, and can accommodate block materials with a maximum particle size of 3-5 times the initial gap between the rollers, avoiding the problem of material jamming caused by excessive feed particle size in traditional jaw crushers. For materials with high moisture content (usually allowed to have a moisture content of ≤ 15%), the extrusion crushing mode of the double roll crusher is not prone to dust adhesion. With the elastic retreat device of the movable roller, even if a small amount of viscous impurities are mixed in the material, they can be smoothly discharged, effectively reducing the risk of blockage in the crushing chamber. For example, when dealing with wet coal, the blockage rate of the double roll crusher is only 1/5 of that of the impact crusher, and the effective operating rate of the equipment can be maintained at over 95%, making it particularly suitable for open-pit mining crushing operations in rainy areas.

Some models are also equipped with grid devices at the feed inlet, which can intercept oversized foreign objects in advance, further improving the reliability of equipment operation and reducing downtime losses caused by foreign object jamming.

6. Low maintenance costs and convenient replacement of vulnerable parts

The vulnerable parts of the double roll crusher are mainly the roller surface and bearings, which are few in quantity and have a simple structure. The maintenance cost is much lower than that of the multi roll crusher and cone crusher. After the wear of the roller surface, if the damage is minor, it can be repaired by on-site welding, and the repair cost is only 1/4-1/3 of replacing the new roller surface; If the wear is severe, the operation of replacing the entire roller body does not require dismantling the equipment body, and can be completed through lifting tools. The replacement time usually does not exceed 8 hours. The bearings adopt a centralized lubrication design, and small equipment can be lubricated through a manual grease gun. Large equipment is equipped with a simple lubrication pump, and regular lubrication can ensure the normal operation of the bearings without the need for professional lubrication system maintenance skills.

According to statistics, the average annual maintenance cost of a double roll crusher is only 30% -40% of that of a cone crusher with the same processing capacity. It is particularly suitable for small and medium-sized enterprises with limited funds and a pursuit of cost-effectiveness, and can effectively reduce the financial pressure on production and operation.

B.Application advantages of double roll crusher

Based on the above structural characteristics, the double roll crusher has formed significant competitive advantages in industrial applications. It can not only meet the basic crushing needs, but also bring direct economic benefits and operational convenience to enterprises. Its advantages are mainly reflected in the following five aspects.

1. Low investment cost and short production cycle

The manufacturing cost of a double roll crusher is significantly lower than that of high-end crushing equipment such as multi roll and cone crushers due to its streamlined structure. The market price of a medium-sized double roll crusher with a processing capacity of 50t/h is usually between 100000 and 200000 yuan, which is only one-third to one-half of the same capacity cone crusher. In terms of equipment installation, due to its small size and light weight, there is no need for complex foundation construction. The installation can be completed by leveling the ground and fixing the equipment. The installation cycle is usually 3-7 days, which is significantly shorter than the 15-30 days of jaw crushers. For enterprises that are building new small-scale production lines or upgrading old equipment, choosing a double roll crusher can effectively reduce initial investment pressure, accelerate project production speed, and achieve rapid profitability. For example, a small limestone sand making plant uses a double roll crusher as the core equipment, with a total investment of only 500000 yuan. After being put into operation, the equipment investment cost can be recovered within 3 months, and the return on investment is significantly higher than that of a production line using traditional equipment.

2. The product has excellent particle shape and is easy to process in the future

The extrusion crushing mode of the double roll crusher results in the material being crushed into cubic or nearly circular particle shapes, with fewer edges and reasonable gradation. The fine powder content can be controlled below 8%, and can be directly used for subsequent production without additional shaping treatment. In the production of building aggregates, limestone aggregates crushed by a double roll crusher have a full particle shape and low porosity. The strength of the concrete produced is 10% -15% higher than that of aggregates crushed by an impact crusher; In the coal industry, the crushed clean coal particles are uniform without excessive crushing of coal powder, which can reduce losses during transportation and improve coal combustion efficiency. In addition, the excellent particle shape increases the screening rate of the material by more than 20% in the subsequent screening process, reduces the load on the screening equipment, lowers the rate of unqualified products, and further improves the efficiency of the entire production line.

For production scenarios that require particle shape control, the advantages of double roll crushers are particularly prominent, as they can directly replace the "crushing+shaping" dual equipment combination, simplifying the production process while reducing equipment investment.

3. Widely applicable scenarios, high adaptability to small and medium-sized enterprises

The processing capacity range of the double roll crusher is wide, from 0.1t/h micro equipment for laboratory use to 100t/h large equipment for industrial use, which can be customized to meet the production needs of different scales. Its applicable materials cover various low to medium hardness materials with a hardness of ≤ 150MPa, including coal, limestone, gypsum, shale, bentonite, fertilizer raw materials, ceramic bodies, etc. It is widely used in multiple industries such as mining, building materials, chemical industry, food, and medicine. In small coal mines, double roll crushers are used for crushing raw coal, which can crush large pieces of raw coal to less than 20mm, meeting the requirements of the washing process; In the building materials factory, it is used for gypsum crushing and can accurately control the particle size between 5-10mm to ensure the uniformity of raw materials for gypsum board production; In the food industry, low-speed operation is used for crushing grains and nuts to avoid material overheating and deterioration, ensuring food quality.

For small and medium-sized enterprises with small production scales and diverse material types, the high adaptability of the double roll crusher makes it the preferred equipment. One device can meet the crushing needs of multiple materials, avoiding equipment idle waste.

4. Easy operation and maintenance, controllable labor costs

The operation process of the double roll crusher is simple, requiring only one operator to complete all the work such as equipment start stop, feed adjustment, and gap adjustment. Compared with the requirement of professional operation and maintenance personnel for multi roll crushers, it can significantly reduce labor costs. In terms of maintenance, the daily maintenance of the equipment only includes basic work such as checking the wear of the roller surface, replenishing lubricating oil, and cleaning foreign objects at the feed inlet. No professional technical knowledge is required, and ordinary workers can independently complete it after 1-2 days of training. The equipment failure rate is low, and the average annual downtime is usually controlled within 10 hours, which is much lower than that of complex crushing equipment, effectively improving the equipment operation rate. For example, a small building materials factory uses two double roll crushers to operate alternately, and can achieve all-weather production with only two operators. The labor cost is reduced by more than 50% compared to the production line using jaw crushers, significantly improving the profitability of the enterprise.

For areas with high labor costs, the simple operation characteristics of double roll crushers can effectively alleviate the labor pressure of enterprises and save long-term operating costs.

5. Green and environmentally friendly standards meet policy requirements

In the context of increasingly strict environmental policies, the low pollution characteristics of the double roll crusher make it easy to meet environmental requirements. In terms of dust control, the equipment adopts a fully enclosed casing design, and the inlet and outlet are equipped with rubber sealing devices, which can effectively prevent dust from escaping. Combined with a simple pulse dust removal device, the workshop dust concentration can be controlled below 20mg/m ³, which complies with the national "Comprehensive Emission Standards for Air Pollutants"; In terms of noise control, operating noise below 85 decibels does not require additional noise reduction treatment to meet the workshop noise limit requirements; In terms of energy consumption, low unit energy consumption significantly reduces the carbon emissions of equipment compared to traditional crushing equipment, which is in line with the "dual carbon" development goal.

For example, a small mine in a certain area faced closure due to environmental non-compliance. After replacing the original impact crusher with a double roll crusher, the dust concentration in the workshop decreased from 80mg/m ³ to 15mg/m ³, and the noise level decreased from 105 decibels to 82 decibels. It successfully passed the environmental inspection and achieved compliant production.

The double roll crusher has always occupied an important position in the field of crushing medium and low hardness materials due to its core characteristics of simple structure, low investment cost, convenient operation and maintenance, excellent product quality, as well as outstanding advantages such as adaptability to small and medium-sized enterprises and compliance with environmental protection requirements. Although it lacks the multi-stage crushing capability and intelligent control level of multi roll crushers, it demonstrates irreplaceable value in scenarios that pursue cost-effectiveness and simplify production processes. With the development of manufacturing technology, double roll crushers are also constantly being upgraded, such as using hydraulic adjustment clearance, equipped with basic intelligent monitoring devices, and improving the wear resistance of roller surfaces, further enhancing their market competitiveness. For enterprises, choosing a double roll crusher is not simply a pursuit of technological advancement in equipment, but a rational decision based on their own production scale, material characteristics, and cost budget. Fully leveraging the advantages of the double roll crusher can achieve "low-cost, high-efficiency, and high-quality" operation of the crushing process, laying a solid foundation for enterprises in fierce market competition. In the future, with the continuous tightening of environmental policies and the continuous development of small and medium-sized enterprises, the double roll crusher will continue to maintain strong vitality in the industrial crushing field with its unique advantages, providing reliable equipment support for various basic industrial production.

Save Time! Get A Detailed Quotation Quickly.