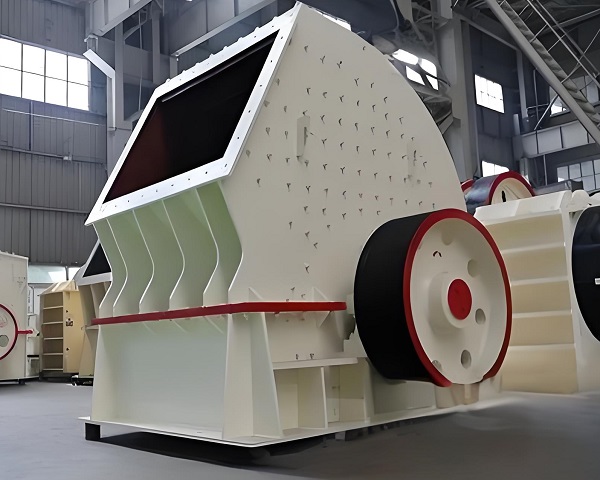

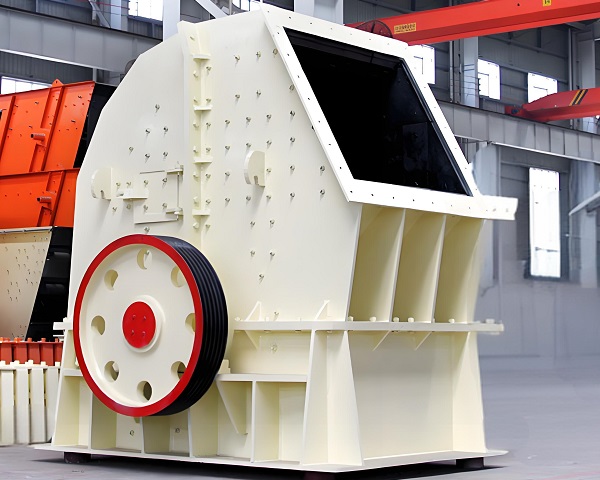

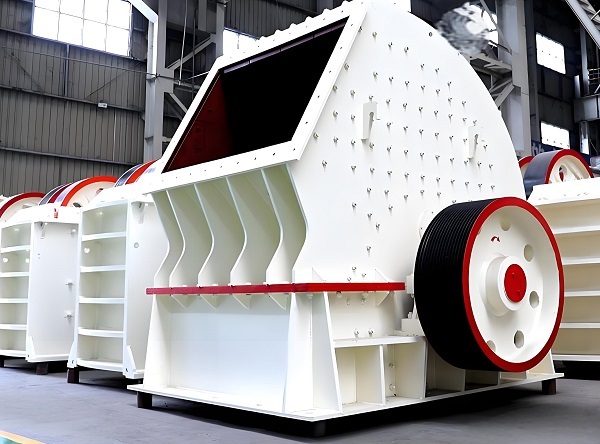

As a key crushing equipment in industries such as mining and building materials, the long-term stable operation of impact crushers directly depends on scientific maintenance and routine upkeep. During daily use, factors such as material wear, component aging, and improper operation can easily lead to problems such as abnormal vibration, uneven particle size, and downtime, severely impacting production efficiency and operating costs. This article, based on the practical operation scenario of a 1600-type impact crusher, systematically outlines implementable maintenance solutions focusing on five core aspects: daily inspection, regular maintenance, core component repair, troubleshooting, and safety regulations. It provides precise guidance for equipment managers, helping to reduce the failure rate, extend equipment lifespan, and ensure continuous and efficient production operations.

I. Core Routine Maintenance: Daily Essential Checks

1. Pre-Start Inspection Procedure

Before starting, complete a triple check of "Appearance - Components - System": Check for overall equipment deformation and loose anchor bolts; use a torque wrench to randomly check bolts in key areas (tightening torque maintained at 300-500 N·m); check the wear condition of the hammer, impact plate, and liner; if chipping, cracks, or excessive wear (hammer wear > 3mm, liner wear > 5mm) is found, immediately stop the machine for repair; check the lubrication system oil level, ensuring that the No. 46 anti-wear hydraulic oil is between the upper and lower limits of the oil gauge, and check for oil leaks; test the electrical control system, confirming that the emergency stop button and overload protection device are sensitive and effective, and that the motor grounding is reliable.

2. Real-time Monitoring During Operation

During equipment operation, record key data every 2 hours: motor current (maintained at 80%-90% of rated value), bearing temperature (≤75℃), and equipment vibration speed (≤4.5mm/s). Observe whether the feed is uniform and the output particle size is stable. If abnormal noise, increased vibration, or abnormal output occurs, stop the machine immediately for troubleshooting. Pay special attention to monitoring the crushing chamber for blockages, especially when processing wet materials; clean residual material every 4 hours to prevent adhesion and accumulation. Simultaneously check the tension of the drive belt; press down on the middle of the belt and control the sinking amount to 10-15mm to avoid slippage or breakage.

3. Cleaning and Maintenance After Shutdown After shutdown, thoroughly clean the equipment surface, crushing chamber, feed inlet, and discharge outlet of any residual material. Use a high-pressure water gun to wash away adhering dirt and dust. Check the tightness of the hammer and liner plates, using anti-loosening washers and double nuts to prevent them from falling off during high-speed rotation. Clean dust from the motor and radiator to ensure effective heat dissipation. Turn off the main power switch and record the equipment operation in the logbook, noting the processing capacity, operating time, fault conditions, and maintenance measures.

II. Regular Maintenance Plan: Precise Maintenance Based on Cycles

1. Weekly Maintenance Items

Perform a comprehensive inspection weekly:

Disassemble and inspect the clearance of the impact frame. Due to wear on the hammer and liner, the clearance may increase; adjust to 10-30mm (adapted to material characteristics), ensuring uniform clearance on both sides (error ≤2mm);

Inspect the transmission system, including pulley alignment (error ≤0.5mm) and coupling coaxiality (error ≤0.1mm); adjust the motor position if necessary;

Clean the lubrication system filter to remove impurities from the oil passages and replenish lubricating oil to the standard level;

Inspect the screen for blockages or damage, cleaning or replacing it promptly.

2. Monthly Maintenance Items

Monthly in-depth maintenance: Disassemble the hammer plates for a comprehensive inspection; grind worn cutting edges (maintaining a consistent 30-45° cutting angle); replace severely worn hammer plates in groups, ensuring a single hammer weight error ≤50g and maintaining rotor balance; check the flatness of the impact plate and liner; correct or replace any dents or deformations, ensuring a tight fit during installation (gap ≤1mm); test the hydraulic adjustment system, checking for leaks in the lead screw and cylinders, ensuring smooth adjustment of the impact frame; tighten all connecting bolts, especially anchor bolts and rotor component bolts, to prevent loosening due to vibration.

3. Quarterly/Annual Overhaul

Quarterly: Change the lubricating oil (after 500 hours of operation); clean the oil tank and oil lines; check bearing wear, measure bearing clearance, and replace bearings immediately if it exceeds 0.3mm; perform insulation testing on the motor, checking winding temperature and terminal tightness; calibrate the sensors and instruments of the electrical control system to ensure data accuracy.

Annually: Conduct a comprehensive disassembly and overhaul, replacing all vulnerable parts (hammer plates, liners, belts, seals, etc.); check the rotor shaft bending; if the deformation exceeds 0.2mm/m, correct or replace it; perform flaw detection on the equipment frame, check for welding cracks, and repair welding promptly; recast the anchor bolt foundation (if there is settlement), ensuring the equipment's levelness and verticality meet standards (horizontal error ≤0.2mm/m, verticality error ≤0.3mm/m).

III. Specialized Maintenance of Core Components: Extending Service Life

Hammer Plate Repair and Replacement Hammer plates are vulnerable core components.

1.Maintenance must follow the principle of "group matching and precise installation": when replacing, group by weight, with a weight difference of ≤100g between groups, and install symmetrically on the rotor to avoid rotational imbalance; use a special grinding wheel for grinding, keeping the cutting edge sharp and the angle consistent, and avoid over-grinding that results in insufficient thickness; select appropriate materials when handling different materials, using Cr12MoV alloy hammer plates for hard materials and high-manganese steel hammer plates for tough materials to extend service life. 1. mpact Plate Maintenance:If the hammer blade shows chipping or cracks, it must be replaced entirely and cannot be used further.

2. Bearing and Lubrication System Maintenance:** Bearing failure is one of the main causes of equipment downtime and requires intensive maintenance: Regularly add lubricating oil to avoid dry friction; replenish oil every 200 hours of operation and completely replace it every 500 hours; during installation, ensure a tight fit between the bearing and shaft, with a clearance controlled at 0.02-0.05mm, and that the seals are intact to prevent dust and lubricating oil leakage; if the bearing temperature exceeds 75℃ or abnormal noise occurs during operation, immediately stop the machine, disassemble and inspect, clean impurities, or replace the bearing to prevent journal wear.

3. Impact Frame and Hydraulic System Maintenance:** The impact frame requires regular inspection of the adjusting screw and cylinder. If jamming or leakage occurs, disassemble and clean the valve core and seals, and replace the aged hydraulic oil; when adjusting the impact frame clearance, both sides must be adjusted simultaneously to avoid deformation caused by unilateral force; if the weld seam of the impact plate cracks, repair it using arc welding, and then grind it smooth after welding. The hydraulic system requires regular venting to prevent air from entering and causing pressure instability. Hydraulic oil contamination levels should be checked quarterly; if impurities exceed standards, it should be filtered or replaced promptly.

IV. Common Fault Repair and Prevention: Quick Troubleshooting

1. Excessive Equipment Vibration When abnormal vibration occurs during equipment operation, the core cause should be investigated first: First, check the rotor balance. If the hammer weight distribution is uneven, it needs to be re-grouped and matched according to weight, ensuring that the weight difference of symmetrically installed hammers is controlled within 100g. If necessary, rotor counterweight calibration should be performed. Second, tighten the anchor bolts and frame connecting bolts using a torque wrench to a standard of 300-500 N·m to prevent bolt loosening due to vibration. Finally, check the rotor shaft bending. If the deformation exceeds 0.2 mm/m, it needs to be corrected or replaced promptly to prevent shaft imbalance from exacerbating vibration. For prevention, the weight grouping requirements must be strictly followed when replacing hammers. Bolt tightness should be checked quarterly. A screening device should be added at the feed front end to prevent large hard impurities from entering the crushing chamber and reduce rotor impact load.

2. Uneven Output Particle Size

When significant deviations occur in the output particle size, three targeted measures are necessary: First, adjust the impact frame gap. Simultaneously calibrate the gap on both sides by rotating the adjusting screw to ensure an error ≤2mm. Set a reasonable range of 10-30mm based on material characteristics and finished product requirements. Second, check the wear of the hammer and impact plate. If the hammer edge wear exceeds 3mm or the impact plate surface is concave, it needs to be ground or replaced promptly to ensure the flatness and sharpness of the crushing impact surface. Third, optimize the feeding process. Check the operating status of the vibrating feeder to ensure that the material is evenly distributed into the crushing chamber, avoiding insufficient crushing caused by unilateral feeding. Preventive measures include implementing a regular gap calibration system, checking the impact frame gap every 8 hours, periodically maintaining core crushing components, and using front-end grading pretreatment to control the feed particle size within the equipment's suitable range, thereby improving crushing uniformity.

3. Motor Overload Tripping

When the motor trips due to overload, immediately stop the machine and investigate: First, reduce the feed rate and clear any blockages in the crushing chamber, unblock the discharge channel, and prevent material accumulation that could lead to a sudden increase in load. Second, check the lubrication of the motor bearings, replenish or replace with No. 46 anti-wear hydraulic oil to ensure smooth bearing operation and reduce frictional resistance. Finally, check the electrical system, ensuring the tightness of the wiring terminals and the sensitivity of the overload protection device. If there are any issues with aging wiring or poor contact, repair or replace them promptly. For routine prevention, strictly control the feed rate within the rated range of 150-250 t/h to avoid overload operation. Regularly perform insulation tests and winding temperature monitoring on the motor to ensure electrical system stability. Also, equip the machine with a comprehensive overload protection device and set a reasonable current protection threshold.

4. Lubricating Oil Leakage For lubricating oil leakage, the sealing and oil circuit system should be thoroughly inspected: First, replace worn seals and gaskets, ensuring a tight seal at bearing end caps, oil circuit joints, and other sealing parts; second, adjust the hydraulic system pressure to the rated range to avoid excessive pressure leading to oil leakage, and tighten oil circuit joints and flange connections; finally, add lubricating oil to between the upper and lower limits specified on the oil level gauge to prevent overflow. Prevention requires establishing a quarterly seal inspection system, promptly replacing worn parts, using lubricating oil of the appropriate specification, regularly cleaning the oil circuit filter to prevent impurities from scratching the sealing surfaces, and maintaining a clean operating environment to prevent dust from entering the oil circuit and affecting the sealing effect.

V. Safety Maintenance Standards: Mitigating Risks and Hazards

All maintenance work must be carried out after the machine is shut down and power is disconnected. A "Do Not Power On" sign must be displayed, and a dedicated person must supervise the process.

When disassembling and installing heavy components (such as hammer plates and rotors), a qualified crane must be used, with a lifting capacity ≥ 1.2 times the component weight. Unauthorized hoisting is strictly prohibited.

When entering the crushing chamber for maintenance, a safety support must be erected to secure the rotor and prevent accidental rotation. Workers must wear safety helmets, protective gloves, and other personal protective equipment.

After maintenance, a no-load test run of 2-4 hours is required to check the equipment's operating status. Load operation can only proceed after confirming there are no abnormalities.

Establish equipment maintenance records, detailing maintenance time, items, and replaced component models, to facilitate traceability and the development of subsequent maintenance plans.

The repair and daily maintenance of the impact crusher are crucial to ensuring the long-term stable operation of the equipment and must consider three dimensions: "daily inspection, periodic maintenance, and specialized repairs." By conducting standardized daily inspections to promptly identify potential problems, carrying out periodic in-depth maintenance to extend component lifespan, and precisely addressing common faults to reduce downtime, we can improve equipment operating efficiency and crushing effect while reducing maintenance costs and safety risks. In practice, it is necessary to develop personalized maintenance plans based on equipment model, material characteristics, and operating environment to ensure that the equipment is always in optimal working condition and provides a solid guarantee for production operations.

Save Time! Get A Detailed Quotation Quickly.