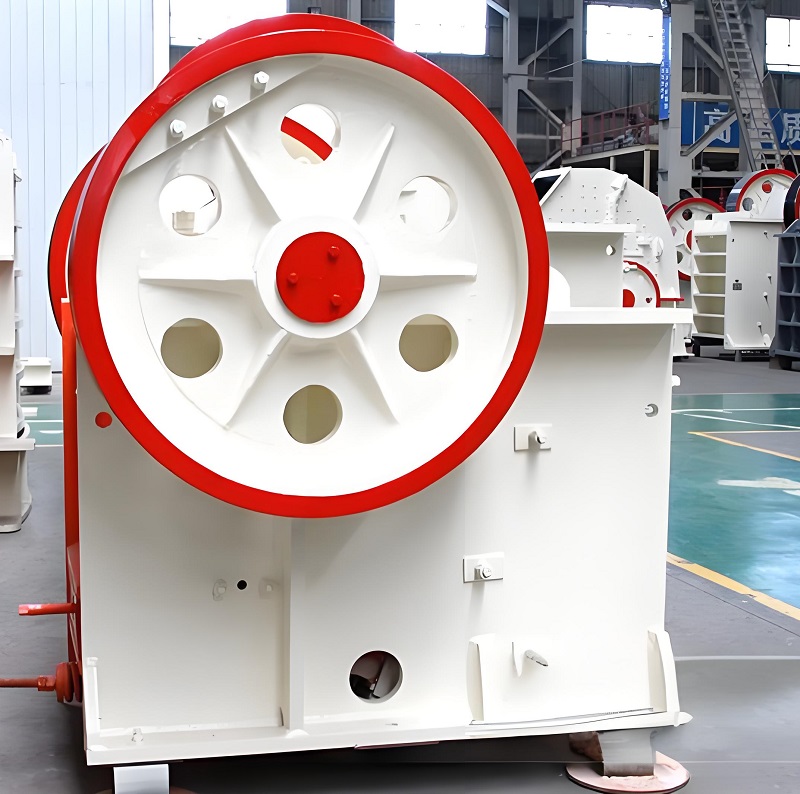

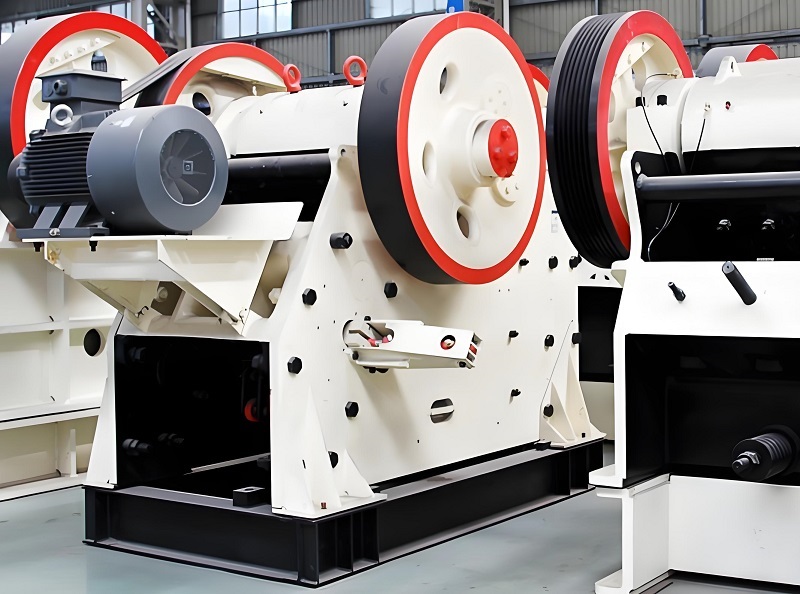

With the rapid development of construction waste recycling, ore processing, and building materials production, jaw crushers have become the mainstream crushing equipment due to their high coarse crushing efficiency and stable operation. However, jaw crushers cannot handle all materials; their structural principles and performance characteristics dictate specific requirements for the materials to be crushed. Using suitable materials maximizes equipment efficiency, while unsuitable materials can shorten lifespan, cause malfunctions, or even render the equipment inoperable. This article details the specific requirements of jaw crushers for crushing materials from five core dimensions: hardness, particle size, composition impurities, humidity, and viscosity. It also identifies prohibited materials and provides optimization solutions to help operators scientifically feed materials, improve crushing efficiency, and extend equipment lifespan.

Jaw crushers utilize a compression-based crushing principle, achieving material crushing through the periodic opening and closing of the movable and fixed jaws. The core components, such as the jaw plates and eccentric shaft, are primarily subjected to compressive stress. Therefore, material hardness is the primary core requirement, directly determining whether the equipment can crush the material, the crushing efficiency, and the wear rate of wear parts. The design compressive strength range of jaw crushers is clearly defined; conventional models are suitable for materials with a compressive strength of 100-320 MPa. This range covers the core materials in most industrial crushing scenarios, which is a key advantage of its adaptability.

Materials within the suitable hardness range are ideal for jaw crushers. For example, concrete blocks, bricks, and rubble from construction waste typically have a compressive strength of 150-250 MPa; limestone, dolomite, and shale in the mining industry have a compressive strength of 100-280 MPa; and gypsum and coal gangue in the building materials industry also meet the requirements. When crushing these materials, the jaw crusher's biting force is uniform, the crushed particles are uniform in size with no excessive pulverization, the jaw plate wear rate is within the normal range, and the replacement cycle can reach 6-12 months, ensuring stable equipment operation without overload risk. Materials exceeding the upper limit of suitable hardness, such as basalt, granite, and high-grade wear-resistant concrete blocks with compressive strength exceeding 350 MPa, are not recommended for direct crushing with a jaw crusher. Forcing such materials into the crusher will lead to rapid wear and chipping of the jaw plates, overloading and fracture of the eccentric shaft, motor overload and tripping, and even deformation of the machine frame. This not only significantly reduces crushing efficiency but also substantially increases equipment maintenance costs. Similarly, materials with excessively low hardness are also unsuitable for crushing solely with a jaw crusher. Materials with compressive strength below 50 MPa, such as foamed concrete and soft coal slag, are prone to excessive pulverization during the crushing process, resulting in a surge in dust, wasting material, and clogging the discharge opening of the crushing chamber, affecting subsequent operations.

The material feed size is a critical requirement for jaw crushers and must precisely match the equipment's feed opening size. This is crucial for ensuring normal feeding and preventing jamming. The feed opening size of a jaw crusher is a fixed parameter, with different models corresponding to specific maximum feed particle sizes. The core rule is: the maximum particle size of the material must be less than 85%-90% of the equipment's feed opening size. Feeding materials exceeding this size is strictly prohibited; this is an absolute rule for jaw crusher operation.

Standard jaw crusher models have clear specifications for feed opening and suitable particle size. For example, the PE-400×600 jaw crusher has a feed opening width of 400mm and a length of 600mm, and the maximum feed particle size should not exceed 340mm; the PE-600×900 model is suitable for a maximum feed particle size of 500mm, and the PE-1200×1500 model is suitable for a maximum feed particle size of 1000mm. This design is because the jaw crusher's crushing chamber has a trapezoidal structure. Oversized materials cannot smoothly enter the crushing chamber and will get stuck at the feed opening, preventing the movable jaw from properly engaging, leading to equipment shutdown, and in severe cases, damaging the transmission system and jaw plates. For materials with excessively large particle sizes, they must be pre-processed through manual cutting, blasting, or coarse crushing to control the particle size within the suitable range before feeding. At the same time, the material particle size should be as uniform as possible to avoid uneven mixing of large and small materials. If large pieces of material are mixed with too many fine particles, the fine particles will fill the gaps in the crushing chamber, preventing the large pieces from being effectively crushed, leading to a "clogging" phenomenon. If all the materials are too small, it will reduce crushing efficiency and increase energy consumption. Therefore, it is recommended to simply screen the materials before feeding to ensure particle size uniformity.

Material composition and impurity content are critical requirements for jaw crushers. Construction waste, ore, and other materials often contain various impurities. The acceptable impurity content is controllable; exceeding the limit or containing specific impurities will seriously affect equipment operation and even pose safety hazards. The core requirements for materials in a jaw crusher are: single composition, no hard, unbreakable impurities, impurity content controlled within 3%, and the type of impurities must meet compatible standards.

Firstly, the material composition needs to be relatively stable, avoiding the crushing of mixed materials with significantly different characteristics. For example, mixing concrete blocks with high-viscosity clay will cause the clay to adhere to the crushing chamber, affecting discharge; mixing bricks and stones with soft plastics will reduce crushing efficiency. Secondly, hard, unbreakable impurities are strictly prohibited. This is a core taboo for jaw crusher operation, mainly including metals (except rebar), hard rock fragments, and glass. Rebar is a common impurity in construction waste, and jaw crushers can handle it. After crushing, the deformed rebar is discharged with the material and can be separated later by magnetic separation. However, the rebar diameter must be controlled within 30mm. Rebar with a larger diameter will get stuck between the moving and fixed jaws of the crushing chamber, causing the equipment to seize up and stop, requiring manual disassembly, which is very time-consuming. Hard metal impurities such as bolts, steel plates, and iron blocks are strictly prohibited from entering the crushing chamber. These impurities have high hardness and no plasticity; during crushing, they will directly impact the jaw plates, causing them to crack. The impact force is also transmitted to the eccentric shaft and bearings, causing component damage. Therefore, these impurities must be removed through manual sorting or metal detectors before feeding. In addition, the content of soft impurities in the material also needs to be controlled, such as plastics, wood, and fabrics in construction waste, and weeds and fibers in ore. If the content exceeds 3%, it will entangle the jaw shaft or block the discharge opening, affecting the crushing rhythm. It is recommended to sort and clean the material beforehand to avoid affecting the normal operation of the equipment.

Material moisture content is a crucial requirement for jaw crushers. Excessive moisture can lead to cavity blockage and material sticking, directly affecting crushing efficiency and product quality. This is a common characteristic of compression-type crushing equipment, and jaw crushers are particularly sensitive to this. The moisture content of the material suitable for jaw crushers needs to be controlled below 8%. This standard ensures that the material does not stick to the cavity or clump during the crushing process, allowing for smooth discharge and ensuring that the moisture content of the finished aggregate meets subsequent usage requirements.

When crushing materials with appropriate moisture content, there is no adhesion between particles, the inner wall of the crushing chamber does not accumulate material, there is no risk of blockage at the discharge opening, the finished aggregate particle size is uniform, and the amount of dust is within a controllable range. For example, dry construction waste, ore, and coal gangue, with a moisture content of 3%-6%, are ideal materials for jaw crushers. However, materials with a moisture content exceeding 8%, such as construction waste that has not been dried after rain, clay ore with a moisture content of over 10%, and wet coal, will experience serious cavity sticking during crushing. The material adheres to the surface of the moving and fixed jaws and the inner wall of the crushing chamber, preventing effective compression and crushing. The accumulation of material leads to cavity blockage and equipment shutdown. At the same time, wet materials tend to clump after crushing, resulting in uneven particle size of the finished aggregate, which cannot meet the requirements for resource utilization. For example, wet concrete blocks will clump after crushing and cannot be used as recycled aggregate. If wet materials must be processed, they need to be dried beforehand to reduce the moisture content to the appropriate range, or a jaw crusher with an anti-sticking cavity design should be selected, using a scraper cleaning device to reduce material adhesion and ensure smooth operation.

Material viscosity is an auxiliary requirement for jaw crushers, related to but fundamentally different from moisture content. Viscosity mainly refers to whether the material is prone to sticking and clumping after being subjected to external force, directly affecting the cleanliness of the crushing chamber and the discharge efficiency. Jaw crushers are suitable for low-viscosity materials and strictly prohibited from processing high-viscosity materials. This is a crucial prerequisite for ensuring continuous operation of the equipment.

The core characteristics of low-viscosity materials are their non-stickiness and ease of dispersion. After crushing, they do not adhere to the equipment components. Examples include concrete, bricks, limestone, and granite (within the applicable hardness range). Even with a moisture content close to 8%, these materials will not cause serious clogging, and the crushed particles will be distinct and the discharge will be smooth. High-viscosity materials, such as clay, silt, highly plastic shale, and asphalt concrete, are not suitable for crushing with a jaw crusher, even if their moisture content is within the applicable range. When compressed, these materials will stick together, adhering to the jaw plates, preventing the movable and fixed jaws from effectively engaging. This significantly reduces crushing efficiency. The accumulated material will also continuously thicken, increasing the equipment's operating load and energy consumption. The crushed product will be in the form of mud lumps, rendering it useless and potentially clogging subsequent conveying equipment. It's important to note that viscosity and humidity are interrelated; high humidity exacerbates the clogging problem with high-viscosity materials, while low humidity can reduce the viscosity of some materials. For example, the viscosity of clay decreases after drying, allowing for small amounts to be mixed with low-viscosity materials for crushing, but crushing them separately is still not recommended.

In addition to the five core requirements mentioned above, jaw crushers have specific prohibited materials. These materials are strictly forbidden from being fed into the jaw crusher regardless of their parameters, as this will cause irreversible equipment damage and even lead to safety accidents. These include: firstly, ultra-high hardness brittle materials, such as diamonds and corundum, whose hardness far exceeds the jaw crusher's applicable limit. Forcing their crushing will directly cause the jaw plates to break and the eccentric shaft to fracture; secondly, flammable and explosive materials, such as calcium carbide, gunpowder, and flammable waste plastics. The friction generated during crushing can easily cause combustion and explosion, posing a significant safety hazard; thirdly, corrosive materials, such as waste residue soaked in strong acids and bases, and corrosive ores, which will corrode the jaw crusher's body, jaw plates, and bearings, shortening the equipment's service life and causing component corrosion and jamming. To address the requirements of jaw crushers regarding the materials they process, operators can optimize the process to better suit the equipment and improve operational efficiency. First, pre-treatment of materials before feeding is crucial. This involves controlling particle size through screening, removing hard impurities through sorting, and reducing moisture content through drying, thus ensuring the material meets the equipment's requirements from the outset. Second, selecting the appropriate equipment based on material characteristics is essential. For high-hardness materials, a heavy-duty jaw crusher is recommended, featuring jaw plates made of high-wear-resistant alloy and a more rigid machine body, allowing it to handle materials with higher hardness limits. Third, regular equipment maintenance is vital, including timely replacement of worn jaw plates and cleaning of material buildup in the crushing chamber, ensuring the equipment remains in optimal working condition and maintains its adaptability.

The requirements of jaw crushers for crushed materials revolve around five core dimensions: hardness, particle size, composition impurities, moisture, and viscosity. Using suitable materials allows the equipment to operate efficiently, stably, and with low energy consumption; conversely, using unsuitable materials can lead to various malfunctions. Operators must strictly adhere to these compatibility standards, properly pre-treat materials, and avoid prohibited materials to maximize the value of jaw crushers in applications such as construction waste crushing and ore processing. This not only improves the economic efficiency of crushing operations but also extends equipment lifespan, contributing to the high-quality development of the crushing industry.

Save Time! Get A Detailed Quotation Quickly.