With the acceleration of urbanization, the generation of construction waste has increased explosively. How to scientifically process construction waste and achieve resource recycling has become a key issue in promoting green urban development. Construction waste contains various components, including concrete blocks, bricks, and waste rebar, and its crushing treatment is a core link in resource reuse. Among numerous crushing equipment, jaw crushers, with their unique structural design and superior performance, have become one of the preferred equipment in the field of construction waste crushing. This article will deeply analyze the core advantages of jaw crushers in construction waste crushing from multiple dimensions, including crushing efficiency, adaptability, stability, economy, and environmental protection, demonstrating their important value in resource recycling.

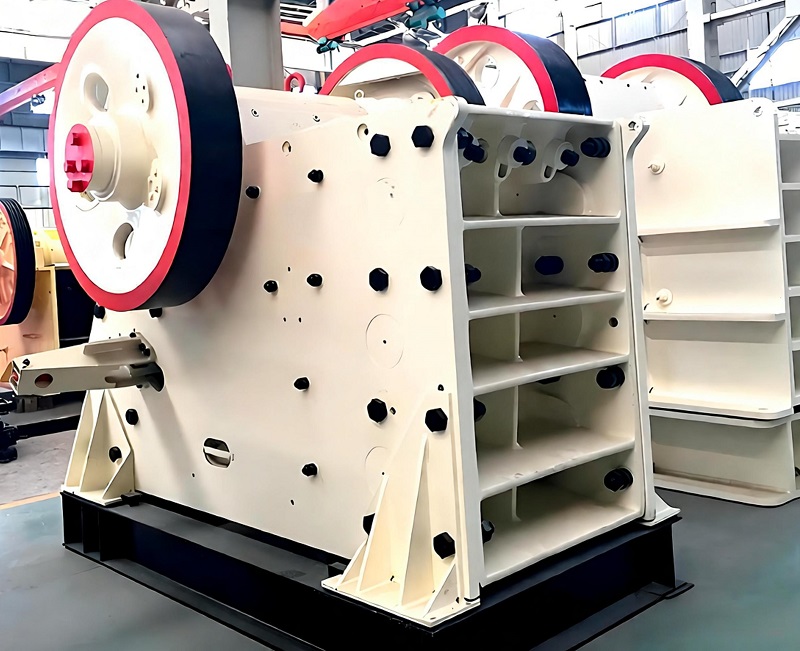

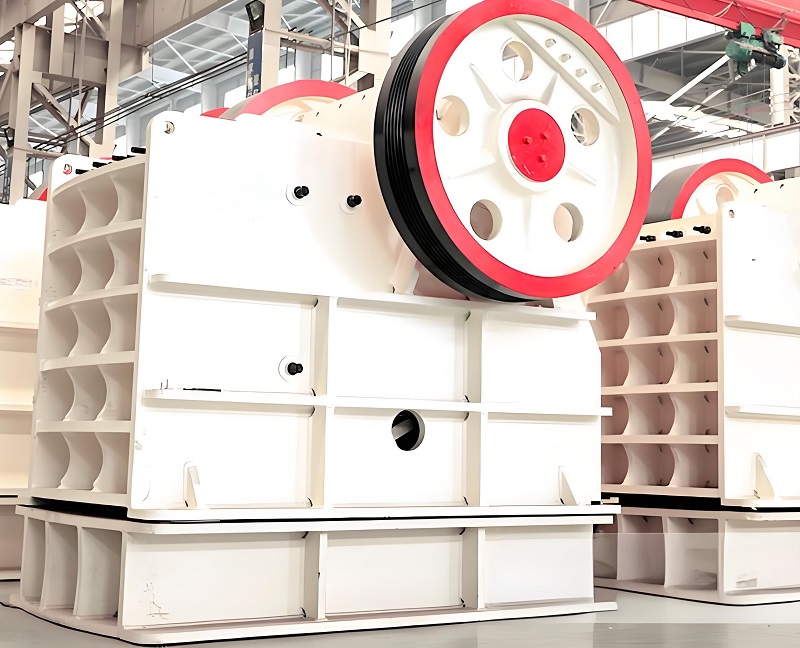

One of the most prominent advantages of jaw crushers is their high crushing efficiency and large processing capacity, which can meet the needs of large-scale construction waste treatment. The processing of construction waste often involves a massive amount of material, especially in large-scale demolition projects and road reconstruction projects, where the daily amount of construction waste can reach hundreds or even thousands of tons, placing extremely high demands on the processing capacity of crushing equipment. Jaw crushers utilize the "compression crushing" principle, using the periodic biting motion of the movable jaw and the fixed jaw to powerfully crush materials. Their large crushing chamber depth and wide feed opening can accommodate larger-sized construction waste raw materials. Taking the commonly used PE series jaw crusher as an example, the feed opening width can reach over 1200mm, and the maximum feed size can reach 1000mm, perfectly adapting to the large-sized concrete blocks and bricks commonly found in construction waste, eliminating the need for excessive pre-sorting and pre-treatment, significantly saving preparation time. At the same time, jaw crushers have a high crushing frequency, with the movable jaw swinging 200-300 times per minute, enabling rapid completion of material crushing. The single-machine hourly output can reach 10-1000 tons, and can be flexibly combined to form large-scale crushing production lines according to processing needs, effectively improving the overall efficiency of construction waste treatment and shortening project cycles.

The strong adaptability to the components of construction waste is a core reason why jaw crushers are widely used. Construction waste has a complex and diverse composition. Besides hard materials such as concrete blocks and bricks, it may also contain impurities such as waste rebar, plastics, and wood. The materials also vary greatly in hardness and particle size, posing a significant challenge to the compatibility and impact resistance of crushing equipment. Jaw crushers have a highly adaptable crushing structure. Their movable and fixed jaws are made of high-strength wear-resistant steel, with a specially hardened surface reaching a hardness of over HRC60. This allows them to withstand the strong impact and wear of hard materials, maintaining stable crushing performance even when crushing concrete blocks with a compressive strength of up to 320 MPa. For metal impurities such as waste rebar mixed in construction waste, the jaw crusher's compression-based crushing method does not damage the equipment—the waste rebar is deformed during the crushing process and discharged along with the crushed material, and can be separated and recycled later using magnetic separation equipment, eliminating concerns about jamming or damage to the equipment from impurities. Furthermore, the crushing chamber type of the jaw crusher can be adjusted according to material characteristics and crushing requirements. By replacing different specifications of jaw plates, it can meet the needs of different crushing stages, such as coarse and medium crushing. It can both crush large pieces of construction waste into primary aggregates and work with subsequent fine crushing equipment to complete fine crushing, adapting to the entire process of construction waste resource utilization.

It boasts strong operational stability and a low failure rate, ensuring the continuous operation of construction waste crushing. Construction waste crushing operations are often conducted outdoors in harsh working environments, where dust, vibration, and temperature fluctuations can affect equipment stability. Equipment failure and downtime directly impact the progress of the entire crushing production line, resulting in significant economic losses. The jaw crusher's simple and rational structural design, with fewer core components and a simple transmission system using V-belt drive, offers high transmission efficiency and easy maintenance, effectively reducing the probability of failure. Its body uses a one-piece cast steel or welded structure, providing high rigidity and the ability to withstand strong vibrations and impacts in outdoor operations. The shock absorption device at the bottom of the machine further enhances equipment stability and reduces the impact of vibration on the surrounding environment and the equipment itself. In addition, the jaw crusher's lubrication system is well-designed, using a centralized lubrication method to provide timely and quantitative lubrication to key components such as bearings, effectively reducing component wear and extending equipment lifespan. Practical data shows that jaw crushers have an average mean time between failures (MTBF) of over 8000 hours, far exceeding other types of crushing equipment, ensuring the continuous and stable operation of construction waste crushing, and are particularly suitable for long-term, high-intensity crushing needs.

They offer superior economic advantages, reducing construction waste treatment costs throughout the entire process, from investment and operation to maintenance. For construction waste treatment companies, equipment economics is a core consideration, and jaw crushers demonstrate significant cost advantages throughout their entire lifecycle. In the equipment investment phase, the relatively simple structure of jaw crushers results in lower manufacturing costs. Compared to cone crushers and impact crushers with equivalent processing capacity, the purchase cost can be reduced by 20%-40%, significantly reducing the initial investment pressure on enterprises. In terms of operating costs, jaw crushers have lower energy consumption; their compression-based crushing method does not require high-speed rotation to crush materials, with a unit energy consumption of only 1-3 kWh/t, far lower than the 3-5 kWh/t of impact crushers. At the same time, their core wear parts (jaw plates) have a long service life, with a replacement cycle of 6-12 months. Jaw plate replacement is simple and convenient, requiring no specialized large equipment, resulting in lower replacement and labor costs. In terms of maintenance costs, jaw crushers have fewer core components and a simple maintenance process. Routine maintenance only requires basic operations such as checking the lubrication system, tightening fasteners, and cleaning the crushing chamber. No professional technical team is needed; ordinary operators can complete these tasks after simple training, significantly reducing maintenance costs. Furthermore, jaw crushers have a long service life, lasting over 10 years under normal maintenance, further spreading the overall cost of the equipment and improving the economic efficiency of enterprises.

They meet green development requirements, exhibiting outstanding environmental performance and contributing to clean construction waste crushing operations. With increasingly stringent environmental policies, the environmental requirements for construction waste crushing operations are constantly rising, and the emission of pollutants such as dust and noise must be strictly controlled within standard limits. Jaw crushers are designed with environmental protection in mind from the outset, using various technical means to reduce pollutant emissions. In terms of dust control, the jaw crusher's crushing chamber adopts a semi-enclosed design, reducing dust leakage; at the same time, the equipment can be equipped with dust removal equipment (such as pulse bag dust collectors), which collects and processes the dust generated during the crushing process through negative pressure adsorption. The dust emission concentration can be controlled below 10mg/m³, meeting national environmental protection standards. In terms of noise control, the jaw crusher's transmission system uses V-belt transmission, reducing noise generated by mechanical friction; the shock absorption device at the bottom of the machine body and the sound insulation cover further reduce vibration noise, and the equipment operating noise can be controlled below 85dB, effectively reducing noise pollution to the surrounding environment. In addition, the crushing process of the jaw crusher does not produce toxic or harmful gases, and the crushed construction waste aggregate can be directly used to produce recycled concrete, permeable bricks, roadbed fillers, etc., realizing the recycling of construction waste, reducing the amount of construction waste landfill, and reducing the occupation of land resources and environmental pollution, which is in line with the development requirements of "carbon peaking and carbon neutrality".

Easy to operate and highly automated, reducing labor costs and operational difficulty. The site environment for construction waste crushing operations is complex, and the technical level of operators varies, making the ease of operation of the equipment crucial. The jaw crusher is equipped with a complete automatic control system, which can realize remote control, automatic start and stop, and overload protection. Operators can complete the start, stop, and parameter adjustment of the equipment through the control cabinet without requiring close-range operation on site, which reduces the difficulty of operation and ensures the safety of operators. At the same time, the overload protection function of the jaw crusher can effectively prevent the equipment from being damaged due to excessive feeding or the inclusion of uncrushable materials—when there is too much material in the crushing chamber or when encountering uncrushable hard objects, the equipment will automatically shut down and send an alarm signal. After the operator cleans it up, it can resume operation, greatly improving the operational safety of the equipment. In addition, some high-end jaw crushers are also equipped with an intelligent monitoring system, which can monitor the operating status of the equipment in real time (such as bearing temperature, lubricating oil level, motor current, etc.). Once an abnormality occurs, the system will automatically warn and provide fault diagnosis suggestions, making it easy for operators to handle in a timely manner, further reducing the difficulty of equipment operation and management.

Wide range of applications and strong versatility, adapting to different scales of construction waste treatment needs. Jaw crushers can be used not only independently for small-scale construction waste treatment projects (such as residential renovation waste treatment and small demolition projects), but also in combination with cone crushers, impact crushers, vibrating screens, conveyors, and other equipment to form large-scale construction waste crushing production lines, adapting to the needs of different scales, such as large demolition projects and urban construction waste comprehensive treatment plants. In combined production lines, jaw crushers usually serve as primary crushing equipment, responsible for crushing large pieces of construction waste into medium-sized materials, which are then further crushed by fine crushing equipment, forming a complete "coarse crushing-medium crushing-fine crushing-screening" process. The crushed aggregate has uniform particle size and reasonable gradation, meeting the needs of different applications. In addition, jaw crushers can also be integrated into mobile crushing stations, forming mobile jaw crushing stations, which have the advantage of flexible mobility. They can be driven directly to the construction waste generation site for crushing operations, eliminating the need to transport construction waste to a fixed crushing site, significantly reducing transportation costs and secondary pollution during transportation. This is especially suitable for construction waste treatment projects that are highly dispersed and difficult to transport.

Jaw crushers demonstrate many core advantages in construction waste crushing, including high crushing efficiency, strong adaptability, good stability, superior economy, outstanding environmental protection, convenient operation, and strong combinability. They perfectly adapt to the complex composition, large processing volume, and harsh environment of construction waste, becoming a core piece of equipment for the resource utilization of construction waste. With the continuous upgrading of construction waste treatment technology, jaw crushers are also constantly being optimized and improved, such as using more wear-resistant materials, improving automation levels, and optimizing environmental performance, further enhancing their advantages in construction waste crushing. In the future, with the continuous advancement of green city construction, the resource utilization of construction waste will become an inevitable trend. Jaw crushers, with their unique advantages, will undoubtedly play an even more important role in the field of construction waste treatment, providing strong equipment support for promoting the recycling of construction waste and achieving green and sustainable development.

Save Time! Get A Detailed Quotation Quickly.