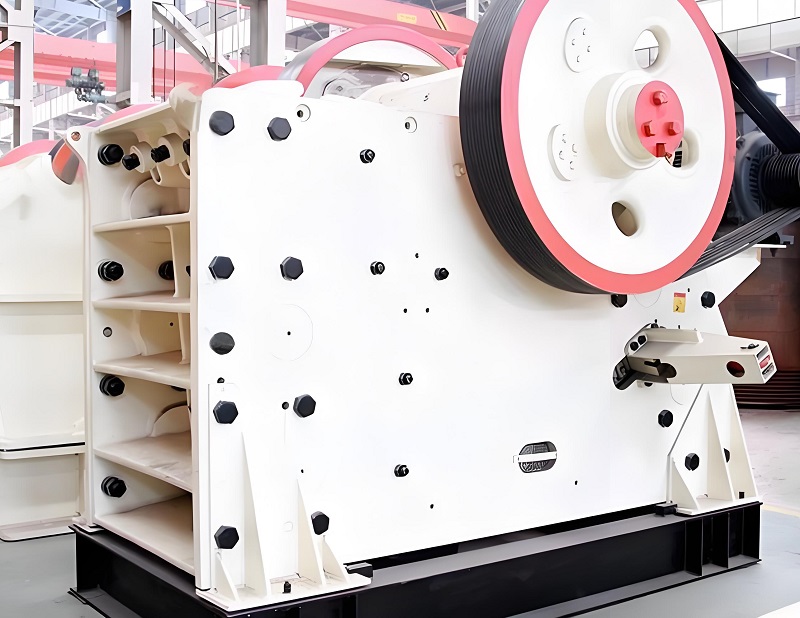

Jaw crushers are core equipment for the coarse crushing of hard materials and are widely used in various fields such as waste disposal and mining. Their safe and standardized operation directly impacts the safety of operators, production efficiency, and equipment lifespan. Because the equipment operates based on the principle of compression and splitting, it is susceptible to material characteristics and operating procedures, and poses risks such as mechanical impact and material splashing. Therefore, strict adherence to all operating guidelines is crucial. This article focuses on the detailed precautions for jaw crusher operation, including pre-start checks, operation, shutdown maintenance, and emergency procedures, providing practical guidance to mitigate safety hazards and ensure stable equipment operation.

As core equipment for coarse crushing, jaw crushers are widely used in waste disposal, mining, and construction processing. Their operational stability directly affects production efficiency, operational safety, and equipment lifespan. Because the equipment crushes hard materials using compression and splitting principles, there are risks of mechanical impact and material splashing during operation, and it is prone to malfunctions due to material characteristics and improper operation. To ensure operational safety and improve equipment efficiency, it is necessary to strictly follow all operating precautions, covering four major aspects: pre-start checks, operation, post-shutdown maintenance, and special scenario management, comprehensively mitigating safety hazards and equipment failures.

Comprehensive pre-start checks are essential for ensuring safe equipment startup. Equipment components, auxiliary systems, and the work environment must be checked thoroughly to prevent starting the machine with existing faults. First, check the mechanical structure, verifying that the jaw plates and liners are not loose or severely worn. If the liners show cracks or excessive wear, they must be replaced promptly to prevent material jamming or equipment damage during crushing. Check the lubrication of rotating parts such as the eccentric shaft and bearings, ensuring sufficient lubricant levels, acceptable oil quality, and no leaks. Insufficient lubrication can lead to component wear and jamming, affecting equipment operation. Second, check the electrical system, ensuring that power and control lines are securely connected, grounding protection is reliable, and components in the distribution box are functioning correctly to prevent electrical faults that could cause equipment shutdown or electric shock. Simultaneously, clear debris from the work area, define a safe operating zone, set up warning signs, and prohibit unauthorized personnel from entering; check that the feed and discharge openings are clear, and remove any residual material to prevent material blockage after startup. Furthermore, the discharge opening size must be adjusted according to the hardness and particle size of the material to be crushed, ensuring that it meets the crushing requirements and preventing blockage due to an opening that is too small, or affecting the crushing particle size if the opening is too large.

Standardized operation during running is key to avoiding safety risks and improving crushing efficiency. Strict adherence to operating procedures and close monitoring of equipment operation status are essential. Operation must be supervised by professional operators; unauthorized and improper operation is strictly prohibited. Feeding should be uniform, avoiding concentrated input of large pieces of material to prevent material from jamming the feed opening; it is strictly prohibited to insert hands or tools into the feed or discharge chambers. If a blockage occurs, the machine must be immediately stopped and the power cut off, and specialized tools should be used for cleaning; cleaning while the machine is running is strictly prohibited. At the same time, the quality of the feed material must be strictly controlled, and flexible materials (plastics, rubber, wood, etc.) and hard metal blocks (rebar, iron blocks, etc.) should be sorted out and removed beforehand. The former can easily entangle equipment components, while the latter can easily damage the jaw plates and crushing chamber, leading to equipment failure. During operation, the equipment's operating sound, temperature, and vibration should be closely observed. During normal operation, there should be no abnormal noise or violent vibration, and the bearing temperature should be controlled within 75℃. If abnormal noise, overheating, or increased vibration occurs, the machine must be stopped immediately for inspection; forced operation is strictly prohibited. In addition, the moisture content of the material must be controlled to prevent high-moisture, sticky materials from entering the equipment and causing blockages; the feeding speed should be adjusted as needed according to the required crushing particle size to avoid overloading and ensure stable operation of the equipment.

Scientific maintenance after shutdown is crucial for extending equipment service life and reducing the frequency of failures. Shutdown operations and subsequent maintenance must be completed according to procedures. When shutting down, feeding should be stopped first, and the equipment power should be turned off only after all the material in the crushing chamber has been discharged, to prevent residual material from solidifying and clumping in the chamber, affecting the next startup. After shutdown, the surface and internal residual materials of the equipment should be cleaned promptly, with particular attention to cleaning the feed chamber, discharge chamber, jaw plates, and liner plates to prevent material corrosion and wear of components. Subsequently, inspect the equipment components for wear and tear, checking each part such as the jaw plates, liners, eccentric shaft, and bearings. Record the degree of wear and replace severely worn parts promptly. Replenish lubricating oil and lubricate rotating parts to prevent corrosion. Simultaneously, inspect the electrical system, clean dust from the distribution box, and tighten loose wiring connections. Organize the work area, neatly arrange tools and materials, and maintain detailed equipment operation records, including start-up time, fault conditions, and maintenance details, for future traceability and repair.

Special scenarios and emergency procedures require strict control to handle complex working conditions and unexpected situations and prevent the escalation of safety accidents. During outdoor operations, ensure proper equipment protection. Avoid outdoor work in rainy weather to prevent rainwater from entering the electrical system and causing short circuits, and implement rain and moisture protection measures. In high-temperature weather, enhance equipment cooling and regularly check the cooling system to prevent overheating of bearings and motors. In low-temperature weather, implement anti-freezing measures to prevent lubricating oil from solidifying and pipelines from clogging. For crushing different materials, optimize the operating procedures. When crushing high-hardness materials, appropriately reduce the feeding speed and regularly check the wear of the jaw plates. When crushing materials containing impurities, add a impurity removal step to prevent impurities from damaging the equipment. If equipment jamming, motor overload, or material splashing occurs during operation, immediately stop the machine and cut off the power supply before troubleshooting. Never operate the equipment while it is powered on. After troubleshooting, conduct a comprehensive inspection of the equipment and restart operation only after confirming that there are no problems.

In daily management, establish a comprehensive equipment maintenance system, conduct regular comprehensive inspections, and identify potential faults. Strengthen operator training, standardize operating procedures, and improve safety awareness and emergency response capabilities to prevent violations of operating procedures. At the same time, strictly comply with relevant safety production regulations, equip with complete safety protection facilities, and regularly check the effectiveness of protective devices to ensure that the entire operation is safe and controllable. Only by fully implementing these precautions can safety hazards be effectively avoided, equipment service life be extended, and the efficiency and safety of crushing operations be improved, meeting the operational needs of various waste crushing and industrial production scenarios.

The safe and efficient operation of the jaw crusher depends on standardized procedures and meticulous maintenance throughout the entire process. From comprehensive pre-startup checks and real-time monitoring during operation, to post-shutdown system maintenance and emergency response in special situations, every step must be strictly implemented to avoid safety hazards and reduce equipment failures. At the same time, improving daily management systems and strengthening personnel training are also crucial for extending equipment lifespan and enhancing operational safety. Strict adherence to all precautions will not only ensure orderly operations but also promote improved efficiency and effectiveness in crushing operations, adapting to the production needs of various industries.

Save Time! Get A Detailed Quotation Quickly.