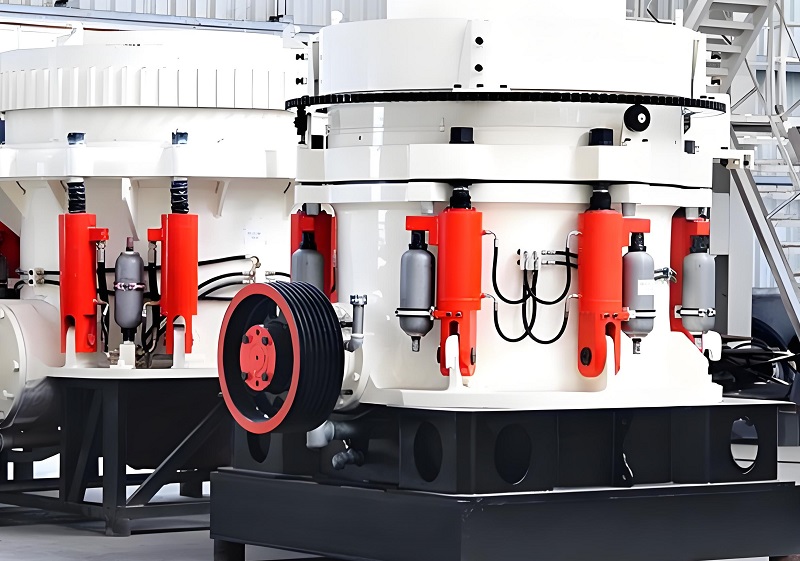

Cone crushers, with their advantages of high crushing ratio, uniform product particle size, and stable operation, are widely used in mining, construction, and waste resource utilization. They are suitable for crushing hard materials in medium and fine crushing operations. The installation accuracy directly determines the equipment's operational stability, while daily maintenance affects its service life and operational efficiency. Improper installation and inadequate maintenance can easily lead to component wear, equipment jamming, and decreased productivity. This article, based on the structural characteristics of the equipment, outlines the installation process and key points of cone crushers, and details daily maintenance procedures to support safe and efficient operation.

Cone crusher installation should follow the principles of "precise positioning, standardized assembly, and rigorous debugging," with thorough preparation to avoid installation deviations. Before installation, the integrity of the equipment components must be checked. Compare the packing list to verify the main machine, motor, hydraulic system, lubrication system, and other components, checking for any bumps, deformation, or damage caused during transportation. Pay particular attention to core components such as the crushing cone, liner plates, and eccentric shaft, and address any problems promptly. Simultaneously, plan the installation site, choosing a flat, solid, and well-ventilated area. The ground bearing capacity must meet the requirements for equipment operation and material storage, preventing later ground settlement that could cause equipment tilting. Clear the site of debris, delineate a safe working area, set up warning signs, and provide necessary lifting equipment and tools. In addition, check the installation foundation, ensuring that the foundation dimensions and elevation meet design requirements, the foundation surface is level, and the pre-reserved holes are accurately positioned. Installation should only begin after the foundation curing is complete.

The installation of core components is crucial, requiring strict control of installation accuracy to ensure coordinated equipment operation. First, install the main machine, lifting it to the pre-reserved position on the foundation. Adjust the horizontality and verticality, using a level and a theodolite to check each point, ensuring that deviations meet the specifications. Then, tighten the anchor bolts, using a secondary grouting process for fixation. After the grouting layer solidifies, recheck the horizontality to prevent loosening. Next, install the crushing cone and eccentric shaft. Ensure the crushing cone is tightly fitted to the eccentric shaft with even clearance to prevent loosening or misalignment, which could cause severe vibration during operation. When installing the liner plates, clean any debris from the crushing cone and the inner wall of the machine frame, apply adhesive evenly, and tighten the liner plate bolts to prevent loosening or detachment during operation. The motor must be installed coaxially with the main machine, the motor base must be securely fixed, and the drive belt or coupling must be installed smoothly with appropriate tension to prevent slippage or abnormal noise during operation. Simultaneously, install the hydraulic and lubrication systems in an orderly manner, ensuring tight seals and no leaks when connecting the pipelines. Verify that the pipeline routing is reasonable, avoiding bending or compression. Add qualified hydraulic oil and lubricating oil, ensuring the oil levels meet the required standards.

After installation, a comprehensive commissioning process is required to eliminate installation hazards and ensure the equipment meets operating standards. Before commissioning, check the connections of all components, tighten all loose bolts, and verify that the electrical, hydraulic, and lubrication systems are functioning correctly, without leaks or loose wiring. Then, perform a no-load test, running the equipment without load for 1-2 hours. Observe the equipment's operating sound, vibration, and the temperature of each component, paying particular attention to bearing temperature, ensuring it does not exceed 75℃. If any abnormal noise, severe vibration, or overheating occurs, immediately stop the machine and investigate the problem. After successful no-load testing, conduct a load test, gradually introducing material, controlling the feeding speed and quantity. Verify that the crushed particle size meets the requirements, adjust the discharge opening size, and observe the hydraulic system pressure and lubrication system operation to ensure stable operation and target production capacity. Only after successful commissioning can the equipment be put into formal operation.

Routine maintenance should be carried out regularly, focusing on lubrication, component inspection, and cleaning to extend the equipment's service life. Lubrication and maintenance are of paramount importance. The core components of a cone crusher experience significant wear during operation, requiring sufficient lubrication. Regularly check the oil level and quality of the lubrication system, and inspect the oil quality weekly. If the oil becomes cloudy or contains impurities, replace it immediately. Thoroughly clean the oil tank and oil filter monthly to prevent impurities from clogging the pipelines and affecting lubrication. Use the appropriate type of lubricating oil based on the ambient temperature; low-temperature environments require low-temperature anti-freeze lubricating oil to prevent oil solidification. Simultaneously, regularly check that the lubrication pipelines are unobstructed and the seals are tight, and promptly address any leaks to prevent component wear due to insufficient lubrication.

Regular inspection and replacement of components are crucial to prevent the escalation of malfunctions. Before each day's operation, check the wear of the liner plates and crushing cone, observing for cracks or excessive wear. Liner plates worn to the specified thickness must be replaced promptly to avoid damage to the equipment body. Check the foundation bolts, liner plate bolts, and other fasteners, and tighten any loose ones immediately. Weekly, check the stability of the hydraulic system pressure and the normal operation of the hydraulic valves and cylinders, inspect the wear of the seals, and replace aging seals promptly. Check the crushing chamber for residual material and clear any blockages. Monthly, comprehensively inspect the wear of the eccentric shaft, bearings, and transmission components, record wear data, and replace severely worn parts promptly. Verify the electrical system wiring, clean dust from the distribution box, and check the reliability of the grounding protection to prevent electrical failures.

Daily cleaning and environmental control are also essential. Daily clean the surface of the equipment and surrounding areas of material dust and debris to prevent dust from entering the equipment and causing component wear or clogging pipelines. Regularly clean residual material from the crushing chamber, feed port, and discharge port to prevent material clumping and blockages. For equipment operating outdoors, implement rain, moisture, and sun protection measures. Avoid outdoor operation during rainy weather to prevent rainwater from entering the electrical system or corroding components. During high temperatures, enhance equipment heat dissipation and clean debris from the heat sinks. During low temperatures, implement anti-freezing measures to prevent oil solidification and pipeline blockages. At the same time, an equipment operation log should be established to record in detail the installation and commissioning, maintenance, parts replacement, and troubleshooting, facilitating subsequent tracing and repair.

The installation accuracy and daily maintenance of the cone crusher directly determine its operating efficiency. Proper installation and commissioning can prevent potential faults from the outset; regular implementation of maintenance procedures can effectively reduce parts wear and tear and lower the frequency of malfunctions. It is necessary to strictly follow the installation process, control the accuracy of each step, and conduct comprehensive maintenance regularly, paying attention to lubrication, inspection, and cleaning. Simultaneously, strengthening professional training for operators and standardizing operating procedures are crucial to ensuring the long-term safe and stable operation of the equipment, improving work efficiency, and meeting the needs of fine crushing operations in various fields.

Save Time! Get A Detailed Quotation Quickly.