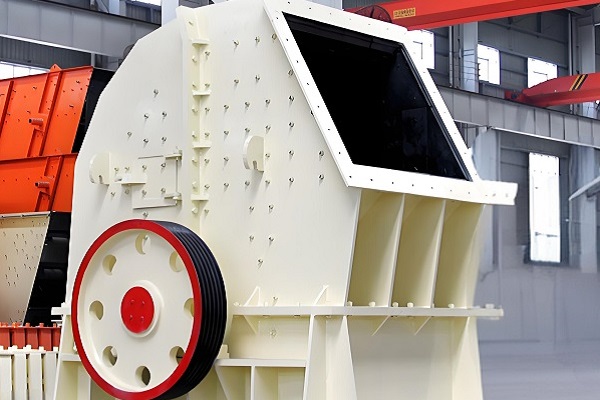

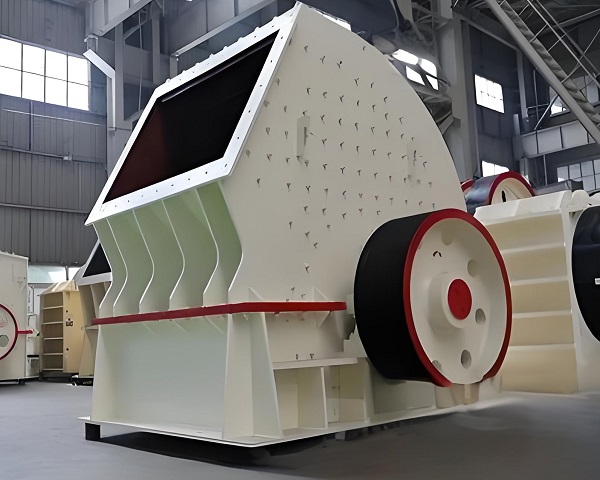

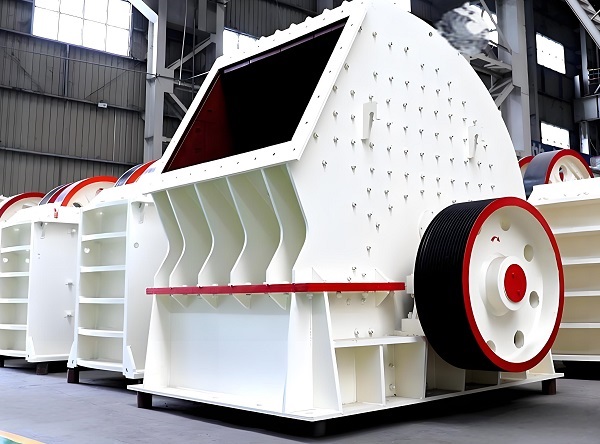

Impact crushers, with their core advantages of high-efficiency crushing and uniform output, are widely used in mining, building materials processing, and other fields. Their crushing effect directly determines the quality of the finished product and production efficiency. In actual operation, problems such as differences in material characteristics, improper parameter settings, component wear, and poor process integration can easily lead to pain points such as uneven output particle size, insufficient capacity, and increased energy consumption. To accurately solve these problems, this article focuses on the practical operation scenario of a 1600-type impact crusher, breaking down scientific and feasible improvement methods from four dimensions: equipment parameter optimization, material characteristic adaptation, core component maintenance, and process upgrade. It provides a systematic guide for industry practitioners, helping to achieve dual optimization of crushing effect and production efficiency.

Precisely Optimizing Equipment Operating Parameters: Controlling the Core Logic of Crushing

1. Reasonably Adjusting the Gap Between the Impact Frame and the Rotor

The gap between the impact frame and the rotor is a key parameter determining the output particle size and needs to be dynamically adjusted according to material characteristics and finished product requirements. For materials with low hardness (such as limestone and shale), the gap can be controlled at 10-20mm to achieve fine crushing. When processing hard materials such as granite and basalt, a gap of 20-30mm is recommended to avoid excessive wear of the hammer and improve crushing efficiency through secondary impact. During adjustment, ensure the gap is uniform on both sides with an error ≤2mm. This can be achieved by rotating the adjusting screw or adding/removing shims. After adjustment, tighten with bolts to prevent displacement during operation. Regularly check for gap changes. As wear on the hammer and liner can cause the gap to increase, calibration is required every 8 hours of operation to ensure particle size stability.

2. Optimize Rotor Speed and Motor Power Matching

Rotor speed directly affects the material impact force and crushing efficiency, and must be adapted according to the equipment model and material characteristics. For the 1600-type impact crusher, a speed of 800-1000 r/min is recommended. Excessive speed can lead to excessive material rebound, reducing crushing efficiency; insufficient speed will not provide enough impact force, resulting in larger output particle size. Simultaneously ensure that the motor power matches the rotor load. 55-75kW motors require appropriate reduction gears to stabilize the motor current at 80%-90% of its rated value, avoiding overload or insufficient power. If the crushing effect is poor and the current is low, the speed can be appropriately increased; if the current is too high and the particle size is uneven, the speed needs to be reduced and the material feed rate checked.

3. Control the feed rate and feed uniformity. Excessive feed rate can easily lead to blockage of the crushing chamber, preventing sufficient material impact and resulting in uneven output particle size; insufficient feed rate leads to high equipment idling rate and wasted capacity. It is recommended to use a vibrating feeder for quantitative feeding. The optimal feed rate for the 1600 type equipment is 150-250t/h (adjusted according to material density), ensuring the crushing chamber is always half-full. During feeding, ensure uniform material distribution to avoid uneven rotor force caused by unilateral feeding, which affects the crushing effect. For large materials (particle size exceeding 80% of the feed inlet), pre-crushing is necessary to control the feed particle size within 300mm, ensuring sufficient contact between the material and the hammer and impact plate, thus improving crushing uniformity.

Scientifically Adapting to Material Characteristics: Reducing Crushing Obstacles

1. Strictly Controlling Material Moisture and Impurity Content

Material moisture directly affects crushing efficiency. Excessive moisture (above 15%) causes material to adhere to the hammer and liner surfaces, forming blockages and reducing crushing efficiency and particle size uniformity. When handling wet materials, pre-drying is necessary, or a desiccant can be added to the feed inlet. Alternatively, the gap between the impact plates can be appropriately increased to prevent material accumulation. Simultaneously, thoroughly remove impurities from the material (such as metal blocks, stones, and wood). Impurities not only damage the hammer and liner but also disrupt the internal flow field of the crushing chamber, leading to incomplete crushing in certain areas. It is recommended to install a screening device and magnetic separator at the feed inlet for pre-treatment to remove impurities and ensure smooth crushing.

2. Select the Appropriate Crushing Mode Based on Material Hardness

Impact crushers have two crushing modes: "stone-on-stone" and "stone-on-iron," which must be switched according to the material hardness. For medium-to-low hardness materials, the "stone-on-stone" mode is used, utilizing the impact between materials to crush them, reducing hammer wear and improving crushing efficiency. For high-hardness materials, switch to the "stone-on-iron" mode, where crushing is achieved through direct impact between the material and the hammers and liners, requiring high-hardness hammer materials. Some equipment has a mode adjustment function, which can be achieved by adjusting the angle of the impact plate. Equipment without adjustment function can be indirectly adapted by controlling the feed particle size and rotation speed to ensure that the crushing force matches the material hardness.

Strengthen Core Component Maintenance: Ensure Stable Crushing Capacity

1. Regularly Maintain the Hammers: Keep Them Sharp and Balanced

The hammers are the core components that directly impact the material; their sharpness and installation accuracy directly affect the crushing effect. When the hammer blade wears more than 3mm or chipping occurs, it must be sharpened or replaced promptly. During sharpening, maintain a consistent blade angle of 30-45°. Replacement should be done in weight groups, with a single hammer weight error ≤50g, ensuring rotor rotation balance. Select hammers of suitable materials: Cr12MoV alloy hammers are used for processing wear-resistant materials, while high-manganese steel hammers are used for processing tough materials to extend service life. Check the hammer fastening every 200 hours of operation, using anti-loosening washers and double nuts to prevent them from falling off during high-speed rotation.

2. Maintenance of Impact Plates and Liners: Optimizing Impact Surface Condition

Wear on the impact plate surface will change the material rebound angle, affecting the crushing effect. Its flatness must be checked regularly. If dents or wear exceeding 5mm occur, replace or repair promptly. As an auxiliary crushing component, the liner must have a rough surface to enhance material friction and prevent slippage. During installation, ensure the impact plate and liner are tightly fitted without looseness, with a gap ≤1mm. Regularly clean any adhering material to the surface to prevent the formation of a smooth surface. For crushing high-hardness materials, a wear-resistant alloy layer can be welded to the surface of the impact plate to improve impact effect and component life.

3. Ensure the stability of the lubrication system and transmission components. Lubrication system failure can lead to unstable rotor speed, affecting the transmission of crushing force. Regularly check the lubricating oil level, using No. 46 anti-wear hydraulic oil, maintaining the oil level between the upper and lower limits of the oil gauge. Change the lubricating oil every 500 hours of operation and clean impurities from the oil passages. Check the drive belt tension; the belt's center deflection should be controlled at 10-15mm, and the pulley alignment error ≤0.5mm to prevent belt slippage and speed fluctuations. The bearing temperature must be controlled below 75℃. If abnormal temperature rise occurs during operation, stop the machine immediately for inspection to prevent bearing damage that could affect rotor rotation accuracy.

Optimizing Process Flow and Site Environment: Building an Efficient Crushing System

1. Improving Front-End Pre-treatment Process

Front-end pre-treatment is fundamental to improving crushing efficiency. Screening and grading devices must be installed to separate materials of different particle sizes, preventing uneven crushing caused by mixing large and small materials. For materials with high mud content, a washing process should be added to remove mud and impurities, preventing blockage of the crushing chamber. Iron removal equipment should be installed to thoroughly remove metal impurities from the material, protecting the hammer and liners. The particle size of the pre-treated material must be controlled within the allowable range of the equipment's feed inlet, with the maximum particle size not exceeding 80% of the feed inlet width, ensuring that the material can smoothly enter the crushing chamber and be fully crushed.

2. Optimizing Back-End Grading and Circulating Crushing

A vibrating screen is used for grading and screening at the back end, returning unqualified coarse materials to the crushing chamber for secondary crushing, forming a closed-loop processing system. Select a screen with an appropriate aperture size according to the finished product requirements; the screen aperture should be 5-10mm smaller than the target output particle size to ensure grading accuracy. Adjust the angle of the discharge conveyor to avoid material accumulation and ensure screening efficiency. If the proportion of coarse material in the finished product is too high, check the clearance of the impact frame and the wear of the hammers, and increase the circulating crushing ratio. If there is too much fine material, the clearance can be appropriately increased and the secondary crushing frequency reduced.

3. Improve the on-site operating environment. Keep the equipment operating environment dry and well-ventilated to avoid rust and material adhesion caused by dampness. Construct a rain shelter to prevent rainwater from entering the crushing chamber and affecting the crushing effect. Control the dust concentration on site and install dust collection equipment to prevent dust from adhering to the equipment surface and affecting heat dissipation and component operation. Regularly clean residual material from the crushing chamber, stopping the machine for cleaning every 4 hours of operation to prevent material accumulation and hardening. Maintain the equipment's horizontal stability and regularly check the tightness of the anchor bolts to prevent operational vibration from causing equipment displacement and affecting crushing accuracy.

Improving the crushing effect of an impact crusher is a systematic project that requires the organic integration of parameter optimization, material adaptation, component maintenance, and process adjustment. By precisely controlling the impact frame gap, optimizing rotor speed, and ensuring uniform feeding, crushing efficiency is improved at the core operational level. External interference factors are reduced through material pretreatment and adaptation to crushing modes. The crushing capacity of the equipment is maintained through regular maintenance of core components such as the hammers and impact plates. An efficient closed-loop system is constructed by improving both front-end and back-end processes. In practice, the scheme needs to be dynamically adjusted according to material characteristics and finished product requirements, and the crushing effect needs to be monitored regularly to promptly identify problems in order to achieve the goals of uniform particle size, stable production capacity, and controllable costs, thus fully leveraging the technical advantages of the impact crusher.

Save Time! Get A Detailed Quotation Quickly.