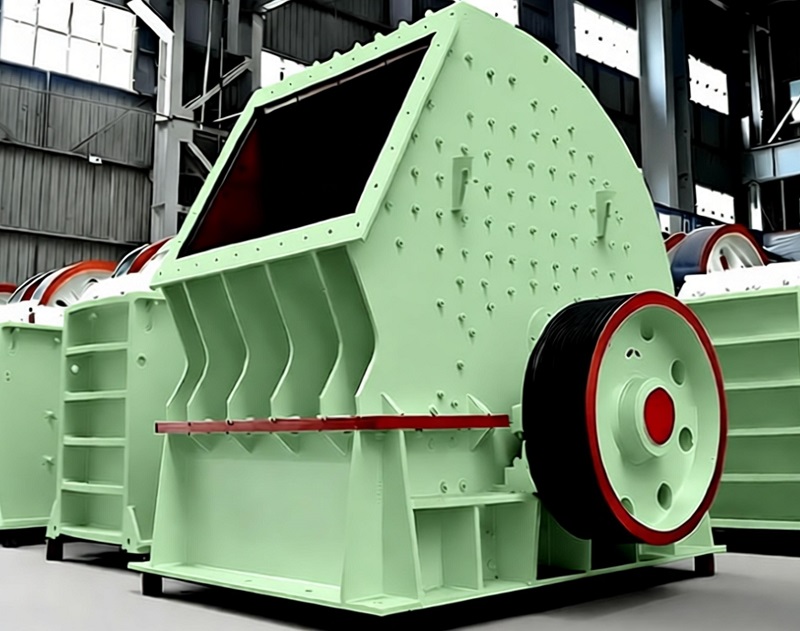

As the core equipment of the crushing production line, the installation and commissioning quality of the impact crusher directly determines the equipment's operational stability, crushing efficiency, and service life. Scientific and standardized installation can prevent problems such as abnormal vibration, excessive wear of components, and insufficient capacity during equipment operation. Precise commissioning allows the equipment to reach its optimal operating state and fully utilize its technical advantages. This article, combining industry standards and practical experience, elaborates on the key points of impact crusher installation and commissioning from four dimensions: pre-installation preparation, core installation process, precise commissioning steps, and installation and commissioning precautions, providing comprehensive guidance for on-site operations.

1.Pre-installation Preparation: Laying the Foundation for Safe Installation

Thorough preparation before installation is the prerequisite for efficient and safe installation work. It requires comprehensive planning from four aspects: site, equipment, personnel, and tools, to avoid installation interruptions or safety hazards due to insufficient preparation.

Site preparation is the primary step. Based on the model specifications of the impact crusher and production process requirements, the installation site should be reasonably planned to ensure that the site area meets the needs of equipment placement, operation, and subsequent maintenance. Space should also be reserved for the installation of feeding and discharge conveying equipment. The ground of the site needs to be hardened with concrete pouring, with the thickness determined according to the weight of the equipment (for heavy equipment, a thickness of not less than 20cm is recommended) to ensure that the ground bearing capacity meets the equipment's operating requirements and prevents equipment tilting due to ground subsidence. In addition, the site needs to have a proper drainage design, with drainage ditches or slopes to prevent rainwater and production wastewater from accumulating and affecting equipment operation; at the same time, the power line laying channels should be planned to ensure that the lines are laid properly, away from rotating parts of the equipment, to avoid safety accidents.

Equipment and component inspection is a core content. After the equipment arrives, professional personnel should organize a thorough check against the delivery list to verify whether the main body of the equipment, wear parts, fasteners, seals, and random accessories (such as instruction manuals, certificates of conformity, special tools, etc.) are complete, and whether there are any deformations, bumps, or damage caused during transportation. Key components such as the rotor, impact plates, hammerheads, and bearings should be inspected. Confirm that the rotor has no cracks or deformation, the hammerhead mounting surface is flat, and the bearings are free of rust and rotate smoothly. If any damaged or missing parts are found, communicate with the manufacturer in time for handling. It is strictly prohibited to use unqualified parts for installation. At the same time, equipment components should be classified and placed in an organized manner with proper labeling to avoid confusion during installation.

Personnel and tools must be prepared simultaneously. Installation and commissioning personnel must possess professional qualifications, be familiar with the structure and working principles of the impact crusher and its installation specifications. Technical training should be organized in advance to clarify the installation process, job responsibilities, and safety precautions. Regarding tools, lifting equipment (such as cranes and forklifts), measuring tools (such as spirit levels, tape measures, and dial indicators), fastening tools (such as torque wrenches and wrench sets), welding equipment, and commissioning instruments should be prepared to ensure that the tools are in good working condition and meet the required accuracy for installation and commissioning.

2. Core Installation Process: Standardized Operation Ensures Installation Quality

The installation of the impact crusher must follow the principle of "foundation first, then equipment; main body first, then accessories; fixing first, then connecting." The process should proceed step by step in the order of foundation pouring, main body installation, accessory installation, and pipeline connection. Emphasis should be placed on controlling installation accuracy to avoid problems such as component misalignment and loose connections.

Foundation pouring and equipment positioning are critical steps in the installation. Based on the foundation drawings provided in the equipment manual, precise line marking and positioning should be performed to determine the installation position, depth, and dimensions of the equipment anchor bolts. During foundation pouring, the concrete mix ratio must be strictly controlled, and anchor bolts or pre-reserved bolt holes should be embedded. The anchor bolts must be installed vertically, with a deviation of no more than 1mm/m, and sufficient tightening length should be reserved at the top of the bolts. After the concrete pouring is completed, curing is required for at least 7 days. Only when the concrete strength reaches more than 80% of the design requirements can the equipment be lifted. When lifting the equipment, lifting equipment that meets the load-bearing requirements must be used, and the lifting points must be selected at the designated positions on the equipment to avoid damaging equipment components during the lifting process. After the equipment is lifted into place, a spirit level should be used to adjust the equipment's levelness. The longitudinal and transverse level deviations of the machine body should not exceed 0.5mm/m. At the same time, the center position of the equipment should be adjusted to ensure alignment with the centerlines of the feeding and discharging equipment. After the adjustment is completed, the anchor bolts should be tightened, and secondary grouting should be used to enhance the stability of the foundation.

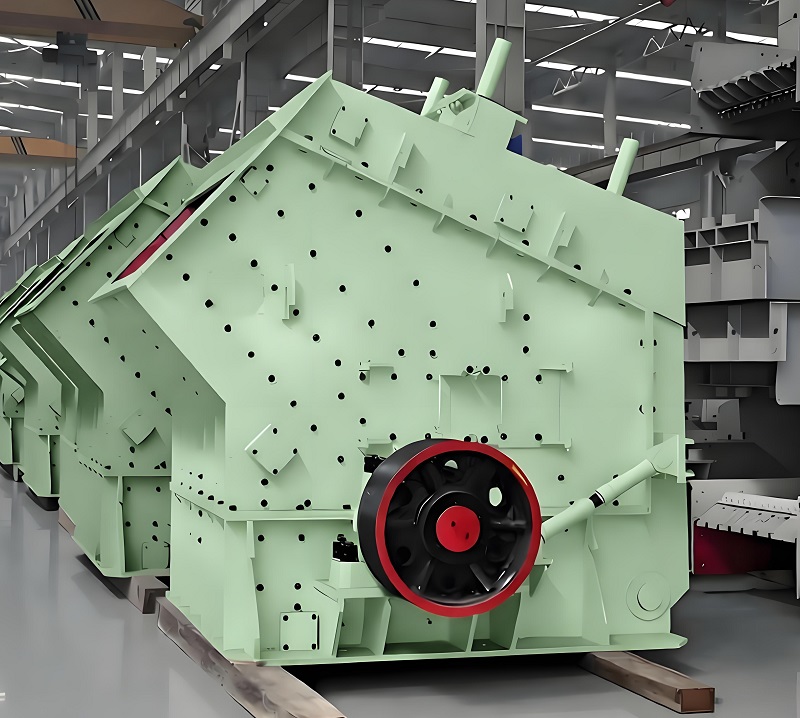

The installation of the main components requires precise attention to detail. First, the frame is installed. The frame is the supporting foundation of the equipment, and it is necessary to ensure that the frame connections are secure and the connections are well-sealed to avoid problems such as material leakage and vibration during operation. Next, the rotor assembly is installed. The rotor is the core moving part of the impact crusher. Before installation, the straightness of the rotor shaft and the flatness of the bearing seat must be checked. After installing the bearings onto the rotor shaft, apply sufficient lubricant, then lift the rotor assembly into the bearing seat of the frame, and adjust the bearing clearance to ensure that the rotor rotates smoothly without jamming. The blow bars must be installed strictly according to the instructions, fixing them to the rotor hammer disc. Ensure the correct installation direction of the blow bars and that the tightening torque of the bolts meets the standard (usually tightened according to the torque value provided by the manufacturer, avoiding overtightening or undertightening). Also, ensure that the weight difference between the blow bars on the same rotor does not exceed 50g to prevent severe vibration caused by imbalance during rotor operation. For the impact plates, adjust the gap between them and the rotor. The initial gap should be set according to the equipment manual (usually 20-50mm), ensuring a uniform gap and that the fixing bolts are tightened properly to prevent the impact plates from shifting during operation.

Accessory and piping installation must be carried out in an orderly manner. Install the feed inlet, discharge outlet, dust cover, and other accessories in sequence. The feed inlet needs to be precisely connected to the feeding equipment to prevent material spillage during transportation; the dust cover must be tightly sealed to reduce dust leakage. Piping connections mainly include lubrication pipelines and cooling pipelines (equipped on some large equipment). Before connecting, clean the pipelines to ensure they are unobstructed. Use sealing components at the connections to prevent leakage of lubricating oil or coolant. Simultaneously, install the electrical control system, connecting the motor, sensors, control cabinet, and other electrical components. Wiring connections must be standardized, and proper grounding must be ensured to guarantee the safe operation of the electrical system.

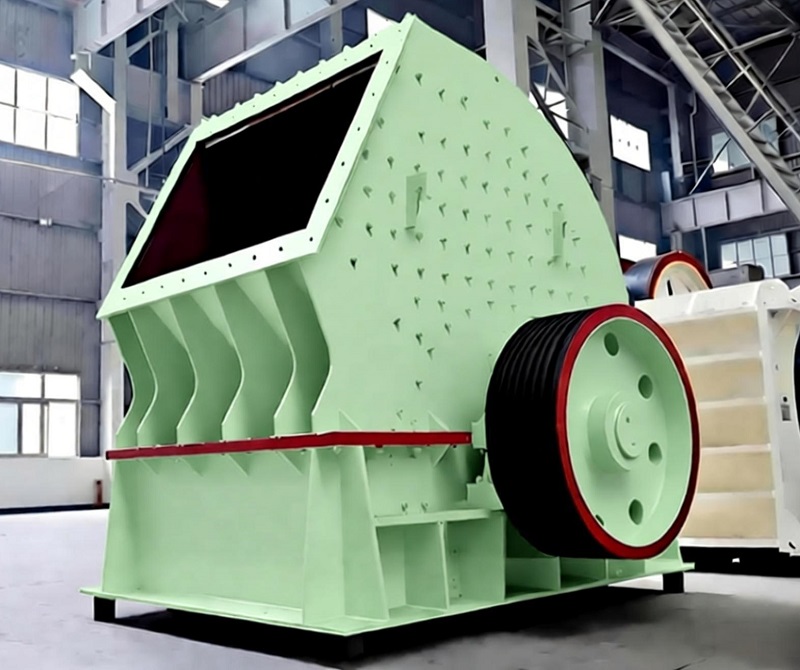

3. Precise Debugging Steps: Bringing the Equipment to Optimal Operating Condition

After installation, system debugging is required. Problems are gradually identified and resolved through no-load and load debugging, optimizing operating parameters to ensure that all performance indicators of the equipment meet the standards. Before debugging, re-check the connections of all components, lubrication status, and electrical system. After confirming everything is correct, start the debugging process.

No-load debugging is a fundamental step, mainly to test the coordinated operation of all components of the equipment. First, start the lubrication system, check whether the lubrication pump is operating normally, and whether the lubrication oil pressure and flow rate meet the standards, ensuring sufficient oil supply to all lubrication points. The main motor of the equipment is then started using the jogging method. Observe the equipment for any jamming, abnormal noise, or other issues. After confirming that there are no abnormalities, perform continuous no-load operation for at least 2 hours. During operation, key indicators such as rotor speed, equipment vibration, and bearing temperature should be monitored. The bearing temperature should be controlled below 60℃, with a maximum of 75℃, and the effective value of vibration velocity should not exceed 4.5 mm/s. Simultaneously, check whether the gap between the hammer and the impact plate is stable, whether there is air leakage at the feed and discharge ports, and whether the electrical system is operating normally. If any abnormality is found, stop the machine immediately for troubleshooting and repair.

Load testing is a core step, aiming to verify the crushing performance and operational stability of the equipment. The load needs to be gradually increased to the rated capacity. First, perform low-load testing, controlling the feed rate to 30%-50% of the rated capacity. Start the production line and observe the material crushing situation, discharge particle size, and equipment operating status. Focus on checking the crushing effect of the material in the crushing chamber. If insufficient crushing or oversized discharge particles occur, adjust the impact plate gap or rotor speed; if increased equipment vibration or abnormal motor current occurs, stop the machine to check whether the feeding is uniform and whether the component connections are loose. After stable low-load operation, gradually increase the feed rate to the rated capacity for full-load testing, with a full-load operation time of at least 4 hours. During the testing process, monitor motor current, equipment vibration, bearing temperature, and discharge particle size in real time to ensure that the motor current is stable within the rated range, the discharge particle size meets production requirements, and the equipment has no significant abnormal noise or vibration. Also, check the wear of vulnerable parts. If abnormal wear occurs, analyze the cause and make adjustments.

Parameter optimization is the crucial final step of the commissioning process. Based on the load testing results, optimize the core operating parameters, including rotor speed, impact plate gap, and feed speed. Based on the characteristics of different materials, adjust the rotor speed (higher hardness materials require a higher speed to increase the impact force; medium and low hardness materials can use a lower speed to reduce energy consumption); precisely adjust the gap between the impact plates according to the required output particle size (a smaller gap results in finer output particles; a larger gap results in coarser output particles); achieve uniform feeding by adjusting the feeder speed to avoid equipment load fluctuations caused by variations in feed volume. After commissioning, record the optimal operating parameters as the baseline parameters for subsequent production.

4. Installation and Commissioning Precautions: Risk Avoidance and Safety Assurance

During installation and commissioning, strict adherence to safety regulations and technical requirements is necessary. Pay close attention to the following precautions to avoid safety accidents and equipment malfunctions.

Safe operation is the primary principle. Installation and commissioning personnel must wear safety helmets, safety shoes, safety gloves, and other protective equipment. Safety belts must be worn for work at height. When the equipment is running, personnel are strictly prohibited from approaching rotating parts, feed inlets, discharge outlets, and other dangerous areas. Disassembly and adjustment of parts are strictly prohibited while the equipment is running. During lifting operations, a professional must supervise to ensure that the lifting equipment and lifting gear are in good working condition and to avoid overloading. Before commissioning the electrical system, check the insulation of the wiring to prevent leakage accidents.

Precision control is crucial throughout the entire process. Strict control of precision is required during foundation pouring, equipment positioning, and component installation. Key indicators such as body levelness, center alignment, and component gaps must meet the requirements; otherwise, it will lead to increased vibration during equipment operation and accelerated wear of parts, affecting the equipment's lifespan. For example, rotor imbalance will increase bearing load and shorten bearing life; uneven impact plate gaps will lead to fluctuations in output particle size and increased energy consumption.

Lubrication and sealing cannot be ignored. Before installation and commissioning, ensure that sufficient qualified grease or lubricating oil is applied to all lubrication points. The grease type must meet the requirements of the equipment manual to avoid component wear due to poor lubrication. Seals must be properly installed to ensure tight sealing at connections such as the frame, feed inlet, and discharge outlet, preventing material leakage, dust leakage, and lubricating oil leakage.

Commissioning records must be detailed and complete. During the installation and commissioning process, it is necessary to accurately record information such as basic dimensions, equipment positioning data, component clearances, operating parameters, and troubleshooting details, and to establish an equipment installation and commissioning file. These records not only provide a reference for subsequent production and maintenance but also help to quickly identify problems when equipment malfunctions occur, and facilitate communication with the equipment manufacturer regarding after-sales issues.

After the installation and commissioning are completed, the site should be cleaned, tools and accessories organized, and the area around the equipment kept free of debris. Operators should also be trained to familiarize themselves with the operating characteristics, operating procedures, and daily maintenance requirements of the equipment after installation and commissioning, to avoid equipment failures due to improper operation.

The installation and commissioning of an impact crusher is a highly technical and detail-oriented systematic process, where every step directly affects the equipment's operating quality. On-site personnel must strictly follow the equipment manual and industry standards, prepare thoroughly before installation, accurately control installation precision, scientifically conduct commissioning work, and pay attention to safe operation and record keeping. Only in this way can the impact crusher ensure long-term stable operation, fully utilize its advantages of high crushing efficiency and good product particle shape, and provide strong support for the efficient operation of the crushing production line. If complex problems are encountered during the installation and commissioning process, it is recommended to contact the equipment manufacturer's technical personnel in a timely manner to avoid equipment damage or safety accidents caused by blind operation.

Save Time! Get A Detailed Quotation Quickly.