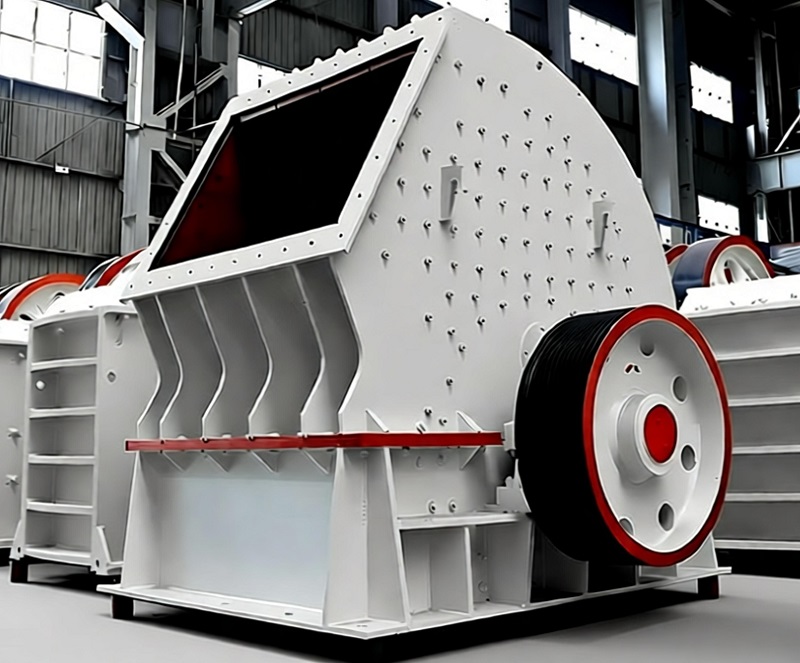

Impact crushers, with their advantages of high crushing ratio, excellent product particle shape, and compact structure, are widely used in various fields such as construction aggregates, mining, and road construction. Crushing efficiency directly determines production progress, operating costs, and economic benefits. Therefore, how to scientifically improve the crushing efficiency of impact crushers has become a core issue for many production enterprises. This article will detail practical strategies for improving the crushing efficiency of impact crushers, combining actual production experience and focusing on several key aspects, including equipment selection, material pretreatment, operating procedures, daily maintenance, and process optimization.

I. Scientific Selection: Laying the Foundation for Efficient Crushing

The model, specifications, and core component configuration of the impact crusher must be precisely matched to the characteristics of the crushed material and production requirements. This is a prerequisite for improving crushing efficiency. If the selection is inappropriate, even with proper subsequent operation and maintenance, it will be difficult to achieve the ideal crushing effect.

1. Selection based on material characteristics. Different materials have significant differences in hardness, humidity, viscosity, and particle size, and thus require different types of crushers. For example, when crushing high-hardness materials such as granite and basalt, a heavy-duty impact crusher with more wear-resistant impact plates and hammers (such as high-manganese steel or high-chromium cast iron) and a higher rotor speed should be selected; while for crushing medium-to-low hardness materials such as limestone and shale, a conventional impact crusher can be used to reduce equipment investment costs. For materials with high humidity (water content exceeding 8%) or high viscosity, a model with an anti-clogging device should be selected to prevent material from sticking and clogging in the crushing chamber and discharge port, affecting crushing efficiency.

2. Determining equipment specifications based on production needs. It is necessary to clearly define the required hourly output and discharge particle size standards in actual production (such as meeting different particle size requirements of 5-10mm, 10-20mm, etc., in aggregate production), and select a model with the corresponding processing capacity. If the actual production demand is far greater than the rated processing capacity of the equipment, it will lead to material accumulation in the crushing chamber, increasing the equipment load, which not only reduces crushing efficiency but may also cause equipment failure; if the equipment specifications are too large, it will cause energy waste and increase operating costs. In addition, to achieve multi-stage crushing, it is necessary to rationally match the models of equipment such as jaw crushers (coarse crushing), impact crushers (medium and fine crushing), and sand making machines (shaping) to ensure that the production capacity of each stage is matched and to avoid situations where there is a bottleneck at the beginning and insufficient material at the end.

II. Pre-processing of Materials to Reduce Crushing Difficulty

The state of the material entering the impact crusher directly affects the crushing efficiency and equipment operating stability. Proper material pre-processing can effectively reduce crushing difficulty, reduce equipment failures, and improve overall crushing efficiency.

1. Strictly control the feed particle size. The feed opening size of the impact crusher has clear limitations. If the feed particle size exceeds the rated maximum value of the equipment, it will cause the material to be unable to enter the crushing chamber smoothly, getting stuck in the feed opening, causing equipment shutdown, and in severe cases, may damage the feeding device, rotor, and other core components. Therefore, before feeding, the material needs to be screened using screening equipment (such as vibrating screens) to remove large pieces of material exceeding the rated particle size, ensuring that the particle size of the material entering the crusher meets the equipment requirements. For large pieces of material, they can be crushed first by coarse crushing equipment such as jaw crushers before being fed into the impact crusher for medium and fine crushing.

2. Reduce material moisture and viscosity. When the material has high water content or high viscosity, it is easy to stick to the inner wall of the crushing chamber, the impact plate, and between the hammers, forming blockages, leading to a reduction in the effective volume of the crushing chamber, insufficient material crushing, and a significant decrease in crushing efficiency. To address this problem, the material can be dried before feeding, such as using dryers or sun drying, to control the water content of the material below 8%. At the same time, a scraper device can be installed at the feed opening to promptly clean the sticky material and prevent blockages.

3. Remove impurities from the material. If the material contains impurities such as metal blocks, wood blocks, and plastics, it will not only affect the quality of the crushed product but also may damage wear parts such as hammers and impact plates, and even cause equipment jamming and shutdown failures. Therefore, it is necessary to install iron removal devices (such as electromagnetic iron removers, permanent magnetic iron removers) and screening devices in the feeding system to promptly remove impurities from the material and ensure the normal operation of the equipment.

III. Standardize Operating Procedures and Optimize Operating Parameters

The operator's skill level and the rationality of the equipment's operating parameters directly affect the crushing efficiency of the impact crusher. Standardizing operating procedures and optimizing operating parameters can maximize crushing efficiency while ensuring the safe operation of the equipment.

1. Standardize feeding operations. Feeding should be uniform and continuous, avoiding sudden increases or decreases in the feed rate. If the feed rate suddenly increases, it will lead to material accumulation in the crushing chamber, exceeding the equipment's processing capacity, resulting in decreased crushing efficiency and a sudden increase in motor load; if the feed rate is too low, it will cause the equipment to "run idle," wasting energy. Uniform feeding can be achieved by installing a quantitative feeder (such as a belt feeder), ensuring that the material in the crushing chamber is in a reasonable filling state, thereby improving crushing efficiency. At the same time, uneven loading of material should be avoided during feeding to ensure that the material is evenly distributed on the rotor, preventing severe localized wear of the hammer plates and impact plates, which would affect the crushing effect.

2. Optimize core operating parameters. The crushing efficiency of the impact crusher is closely related to parameters such as rotor speed, impact plate gap, and hammer plate impact force. Higher rotor speed results in greater impact force on the material and a larger crushing ratio, but excessively high speed will increase equipment load and energy consumption, and may also accelerate hammer plate wear; too low a speed will not achieve the ideal crushing effect. The rotor speed needs to be adjusted through the equipment control system based on the material hardness, particle size, and output requirements to find the optimal speed range. The impact plate gap directly determines the output particle size and crushing efficiency. A smaller gap results in finer output particle size, but greater crushing resistance and lower efficiency; a larger gap results in coarser output particle size and higher efficiency. The impact plate gap should be adjusted regularly based on production needs, maximizing the gap to improve efficiency while meeting the output particle size requirements. In addition, the impact efficiency on the material can be further improved by adjusting the installation angle of the hammer plates to optimize the impact trajectory.

3. Strengthen operator training. Operators need to be familiar with the equipment's structural principles, operating procedures, and fault diagnosis methods to avoid equipment failures or decreased efficiency due to incorrect operation. For example, operators need to observe the equipment's operating status in a timely manner (such as motor current, equipment vibration, noise, etc.). If abnormal conditions such as abnormally high current or increased vibration are detected, the equipment must be immediately shut down for inspection and troubleshooting before resuming operation. At the same time, it is necessary to strictly follow the equipment operating procedures for starting, stopping, and adjusting parameters to avoid damage to the equipment due to improper operation.

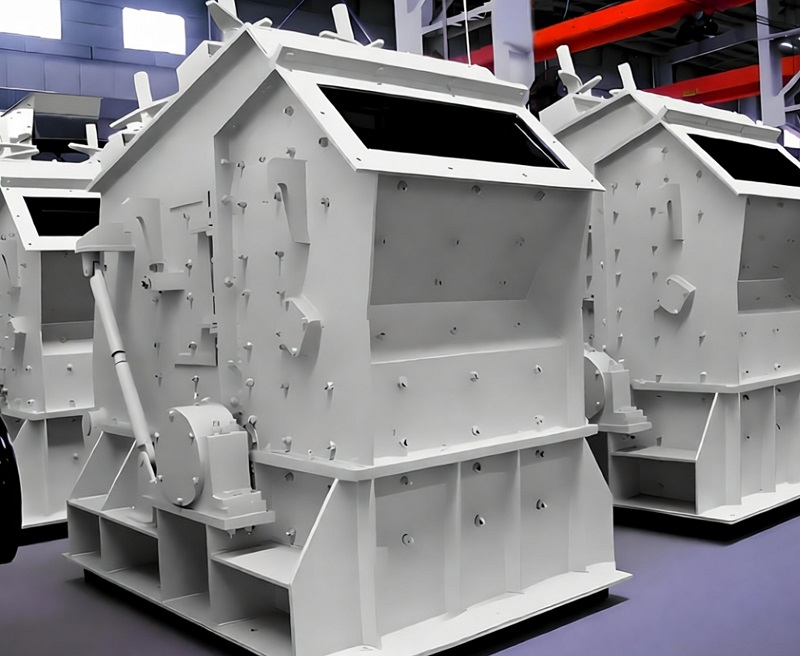

IV. Strengthening Daily Maintenance to Ensure Stable Equipment Operation

During long-term operation, wear parts such as hammer plates, impact plates, and liners of the impact crusher will gradually wear out, and core components such as bearings and motors may also malfunction. If not maintained in a timely manner, this will lead to a decrease in crushing efficiency and even cause equipment downtime. Therefore, strengthening daily maintenance and timely addressing equipment problems are key to ensuring stable and efficient operation of the equipment.

1. Regularly inspect and replace wear parts. The hammer plate is a core wear part of the impact crusher, and its wear degree directly affects the crushing efficiency. The wear of the hammer plate should be checked regularly (e.g., before starting and after stopping the machine every day). If the hammer plate is severely worn (e.g., the wear amount exceeds the rated value) or shows cracks or fractures, it needs to be replaced promptly. At the same time, regularly check the wear of impact plates, liners, grates, and other components. If severe wear is found, replace or repair them promptly to avoid reduced crushing efficiency due to increased crushing chamber clearance and insufficient impact force caused by component wear. When replacing wear parts, ensure installation accuracy to avoid installation deviations that affect the stability of equipment operation.

2. Perform proper lubrication maintenance. The lubrication of moving parts such as bearings and rotors directly affects the operating resistance and service life of the equipment. The lubrication system should be checked regularly to ensure sufficient and clean lubricating oil and even application of grease. According to the equipment's instruction manual, regularly replace lubricating oil and grease to avoid increased wear of components and increased operating resistance due to poor lubrication, which reduces crushing efficiency. At the same time, check the sealing of the lubrication system to prevent lubricating oil leakage or entry of impurities, which affects the lubrication effect.

3. Regularly clean the inside and surroundings of the equipment. During equipment operation, materials and impurities tend to accumulate in parts such as the crushing chamber, discharge port, and screening device. If not cleaned promptly, this will lead to blockages and affect crushing efficiency. Regular shutdowns are required to clean residual materials and impurities from inside the equipment to ensure the crushing chamber remains unobstructed. Simultaneously, clean up debris around the equipment to maintain a clean operating environment and prevent debris from affecting equipment heat dissipation and normal operation.

4. Establish a comprehensive maintenance record system. Record information such as equipment operating time, maintenance content, replacement of wear parts, and fault handling. By analyzing the maintenance records, understand the equipment's operating patterns and wear characteristics, develop maintenance plans in advance, implement preventive maintenance, reduce equipment failure rates, and ensure long-term stable and efficient operation.

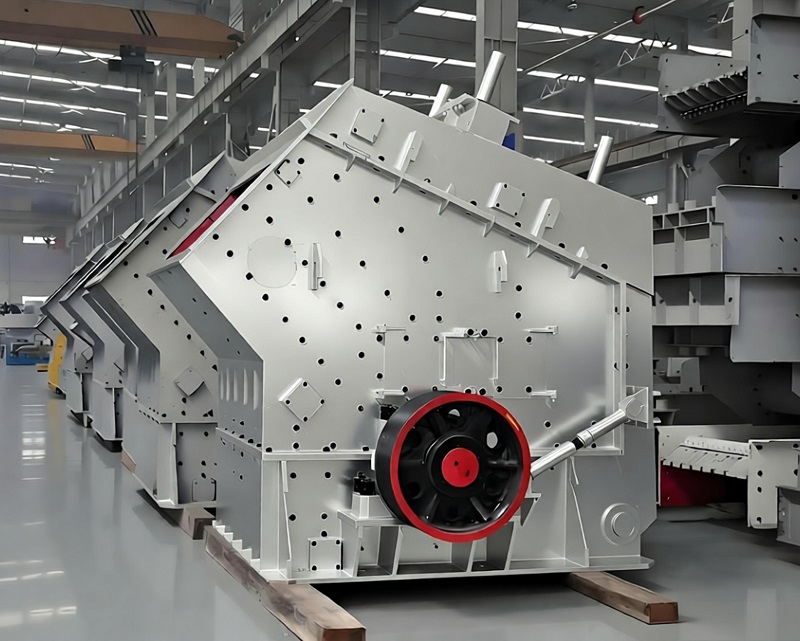

V. Optimizing the Crushing Process to Improve Overall Production Efficiency

In addition to the operation and maintenance of the equipment itself, the rationality of the crushing process also affects the crushing efficiency of the impact crusher. By optimizing the crushing process, efficient coordination of each stage can be achieved, improving overall production efficiency.

1. Optimize the crushing process. For large-scale production projects, a multi-stage crushing process of "coarse crushing + medium and fine crushing + shaping" can be adopted, rationally allocating the crushing tasks at each stage. For example, first use a jaw crusher to coarsely crush large materials, controlling the material particle size within a reasonable range, then send it to the impact crusher for medium and fine crushing, and finally use a sand making machine for shaping to ensure that the output particle size meets the requirements. This process avoids the impact crusher from undertaking excessive coarse crushing tasks, improving its crushing efficiency and service life. At the same time, a circulating screening system can be set up in the crushing process to return unqualified output to the impact crusher for secondary crushing, ensuring product quality and improving resource utilization.

2. Reasonably configure auxiliary equipment. The reasonable configuration of auxiliary equipment directly affects the operating efficiency of the impact crusher. For example, installing efficient dust removal equipment (such as pulse bag dust collectors) can reduce the dust generated during the crushing process, improve the working environment, and prevent dust from entering the equipment and affecting component operation; when installing a vibrating screen, ensure that its screening efficiency matches the processing capacity of the impact crusher to avoid material accumulation due to untimely screening; using an automated control system can achieve real-time monitoring and automatic adjustment of parameters such as feed rate, rotor speed, and impact plate gap, improving operating efficiency and reducing human error.

3. Optimize the production layout. Reasonably plan the installation location of the equipment, shorten the material transportation distance, and reduce material loss and time waste during transportation. For example, equipment such as feeders, impact crushers, and vibrating screens are arranged sequentially according to the production process, and belt conveyors are used to achieve efficient material transfer, avoiding secondary handling of materials. At the same time, maintenance channels and operating spaces are rationally designed to facilitate daily maintenance and operation, thereby improving production efficiency.

Improving the crushing efficiency of impact crushers is a systematic project that requires a scientific and rational plan combining multiple aspects, including equipment selection, material pretreatment, operating procedures, daily maintenance, and process optimization. In actual production, enterprises need to flexibly adjust various strategies based on their material characteristics, production needs, and equipment conditions, continuously summarize experience, and find the most suitable and efficient crushing model. Through scientific management and technological optimization, it is possible to not only improve the crushing efficiency of impact crushers but also reduce operating costs and extend equipment service life, creating greater economic benefits for the enterprise. Meanwhile, with the continuous development of crushing technology, enterprises can actively introduce intelligent and automated equipment and new technologies to further improve the intelligence level and overall efficiency of the crushing production line, adapting to the development needs of industrial production in the new era.

Save Time! Get A Detailed Quotation Quickly.