As a core primary crushing equipment in fields such as mining and construction aggregate production, the quality, performance, and suitability of jaw crushers directly determine the production line's capacity, operating costs, and economic benefits. The market offers numerous brands and models of jaw crushers with significant price variations. Without a systematic understanding, users may encounter problems such as "overpaying for unsuitable equipment" or "buying cheap equipment that is prone to failure." This article, drawing on industry procurement experience, details the considerations for purchasing jaw crushers, covering the entire process from defining needs and brand selection to identifying core equipment performance, contract signing, and after-sales service, helping users accurately select equipment that meets their specific needs.

Clarifying Core Needs: Precisely Defining Equipment Selection Direction

Clearly defining your needs before purchasing is crucial to avoiding blind selection. Users need to consider core dimensions such as material characteristics, capacity requirements, output standards, and site conditions to provide a clear basis for subsequent selection.

First, clarify the characteristics of the crushed material. Different materials have vastly different hardness, moisture content, viscosity, and particle size, requiring different jaw crusher cavity types, jaw plate materials, and motor power. For example, when crushing hard rocks with a hardness of ≥8, such as granite and basalt, a heavy-duty jaw crusher with a deep cavity, high-manganese steel or high-chromium cast iron jaw plates, and a high-power motor is required; for crushing medium-to-low hardness materials such as limestone and shale, a conventional cavity type and ordinary high-manganese steel jaw plates can be used to control procurement costs. If the material's moisture content exceeds 10% or its viscosity is high, a model with an anti-clogging device (such as an extended feed opening or vibratory feeder assistance) should be selected to prevent material from sticking to the cavity walls and causing downtime. Simultaneously, the maximum feed particle size must be determined to ensure that the equipment's feed opening size is compatible, preventing large pieces of material from entering and affecting production.

Precisely determine capacity and output requirements. Based on the overall production line plan, clarify the required hourly capacity of the jaw crusher (e.g., 50 t/h, 100 t/h, 200 t/h, etc.) to avoid mismatches between the crusher's capacity and subsequent secondary and tertiary crushing equipment, preventing situations of "bottlenecking" or "underutilization." The discharge standard needs to be determined based on the end product's application. For example, crushed stone for construction needs to meet a 5-20mm particle size requirement, while mining operations require determining the discharge particle size based on subsequent processing needs, and then selecting the corresponding discharge opening adjustment range—a larger adjustment range allows for a wider range of adaptable discharge particle sizes and greater flexibility. Furthermore, if high requirements are placed on the particle shape of the output, equipment with a wedge-type discharge opening adjustment structure should be prioritized, as it offers higher adjustment accuracy and more uniform particle shape.

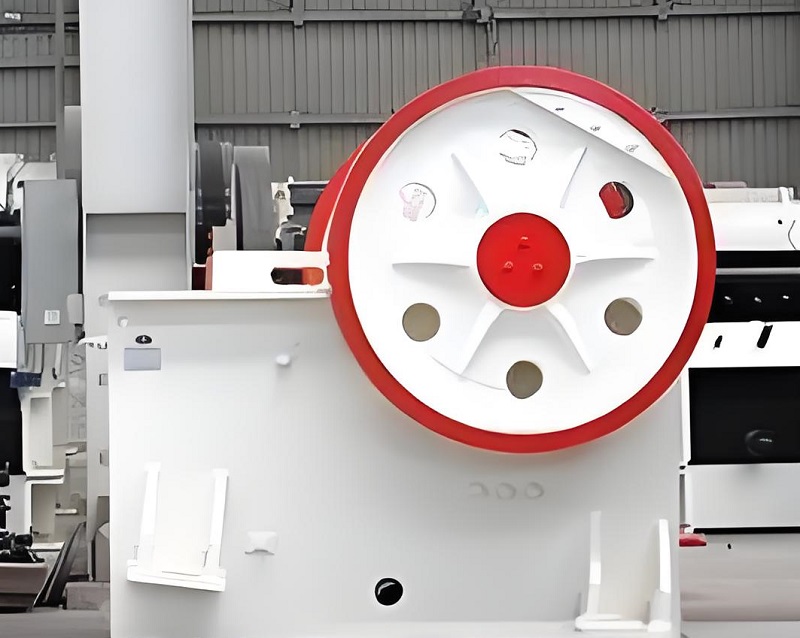

Consider site and working conditions thoroughly. Site area, topography, and power supply capacity directly affect equipment model selection. For small quarries or projects with limited space, a compact PEX fine-crushing jaw crusher can be chosen; for large mines or open-pit sites, a PE coarse-crushing jaw crusher can be used, combined with a large eccentric shaft design to improve crushing efficiency. Power supply conditions must match the equipment's motor power to avoid insufficient voltage preventing the equipment from operating at full load; if the site is located in harsh environments with extreme cold, high temperatures, or excessive dust, it is necessary to communicate with the manufacturer in advance to customize specialized equipment with anti-cold, heat dissipation, and dustproof functions.

2. Selecting High-Quality Brands: A Core Step in Avoiding Procurement Risks

Brand strength directly determines equipment quality, technical level, and after-sales service. Users need to evaluate and select high-quality brands through multiple dimensions to avoid choosing inferior equipment from small workshops.

Prioritize brands with complete qualifications and a good reputation. Verify that the manufacturer possesses core qualifications such as a business license, production license, and ISO9001 quality system certification to ensure legal production capabilities. Learn about the brand's reputation through industry exhibitions, peer recommendations, and online platforms, focusing on user evaluations of equipment stability, failure rate, and after-sales response speed. Request the manufacturer to provide performance cases from the past three years, especially project cases similar to your own working conditions, and conduct on-site inspections of equipment operation to gain a direct understanding of equipment performance. Furthermore, prioritize established manufacturers with more than 10 years of experience in the industry, as they have more mature technology, more stable production processes, and better after-sales service.

Thoroughly investigate the manufacturer's production capabilities. If possible, it is recommended to visit the manufacturer's production workshop to inspect the advanced nature of production equipment (such as CNC lathes, milling machines, and heat treatment equipment), the standardization of production processes, and the quality control system. Focus on the manufacturing process of core components (such as eccentric shafts, jaw plates, and bearings) – high-quality manufacturers use 45# steel for integral forging of eccentric shafts, which are then heat-treated for higher strength; jaw plates are made of wear-resistant alloy materials and heat-treated for longer service life. At the same time, understand the manufacturer's R&D capabilities and whether they can customize equipment according to users' specific needs to avoid production disruptions due to equipment incompatibility with working conditions.

Beware of low-price traps and false advertising. Some small manufacturers on the market sell jaw crushers at prices far below the industry average to gain market share, but their equipment often uses inferior steel and refurbished parts, with rudimentary manufacturing processes. This can lead to failures such as eccentric shaft breakage, rapid jaw plate wear, and frame deformation during operation, resulting in extremely high subsequent maintenance costs. Users need to understand that "you get what you pay for," and when comparing quotes from different manufacturers, focus on equipment configuration, materials, and processes, rather than simply comparing prices. Also, be wary of manufacturers' false claims of "high capacity" and "low energy consumption," and demand third-party test reports or on-site testing to verify the actual performance of the equipment.

3. Identifying Core Equipment Performance: Ensuring Equipment Meets Production Needs

The core performance of the equipment is crucial in determining its service life and crushing efficiency. Users need to focus on cavity design, core component quality, structural stability, and ease of operation.

Pay attention to cavity design and crushing efficiency. Jaw crushers have different cavity types, including deep cavity, standard cavity, and short-head cavity. Deep cavity designs have a deep feed opening and long crushing stroke, enabling "more crushing and less grinding," improving crushing efficiency and reducing material blockage, making them suitable for hard rock crushing; standard cavities have a wide range of applications and are suitable for coarse crushing of medium-to-low hardness materials; short-head cavities produce finer output particle sizes and are suitable for fine crushing operations. Users need to select the appropriate cavity type based on material characteristics and crushing stage, and also consider the optimized design of the cavity, such as whether it uses a "curved cavity" design, which can reduce material slippage and improve the crushing ratio.

Strictly verify the quality of core components. The quality of core components directly determines the equipment's failure rate and service life. The following components require particular attention: First, the eccentric shaft, as the "heart" of the equipment, requires confirmation of its material (preferably 45# steel forging) and heat treatment process (quenching and tempering) to ensure its strength and wear resistance; second, the jaw plates, which should be made of high-manganese steel ZGMn13 or high-chromium cast iron, with a surface hardening treatment and a hardness of ≥HRC55. The installation method of the jaw plates should also be considered, with a quick-change structure being preferred for easier replacement; third, the bearings, for which reputable brands such as SKF and NSK are recommended to ensure strong load-bearing capacity and stable operation, preventing equipment downtime due to bearing failure; fourth, the frame, which should be made of integral cast steel or thick steel plate welded structure, with welds undergoing non-destructive testing to ensure no cracks or deformation, thus improving the overall stability of the equipment.

Structural stability and ease of operation should also be considered. The structural stability of the equipment directly affects operational safety. Check whether the frame connecting bolts are high-strength bolts and whether they are equipped with anti-loosening devices; also check the firmness of the connection between the eccentric shaft and the connecting rod, and whether there are any cushioning devices. Ease of operation can reduce subsequent maintenance costs. Equipment with a hydraulic discharge port adjustment device is preferred, as hydraulic adjustment is more precise and efficient than manual adjustment and allows for remote control; also consider whether the equipment is equipped with an intelligent monitoring system that can monitor indicators such as motor current, bearing temperature, and equipment vibration in real time, facilitating timely fault detection. In addition, the equipment's lubrication system should be comprehensive, using a centralized lubrication method to ensure sufficient oil supply to all lubrication points and reduce component wear.

Equipment energy consumption and environmental performance should be verified. With increasingly stringent environmental policies, energy consumption and environmental indicators must meet requirements. When purchasing, require the manufacturer to provide the equipment's energy consumption parameters (power consumption per unit of production capacity), and prioritize energy-efficient equipment, such as models using variable frequency motors, which can automatically adjust the speed according to the feed rate, reducing energy consumption. In terms of environmental protection, confirm whether the equipment is equipped with a sealed dust cover and dust removal interface that can be connected to a pulse bag dust collector to reduce dust spillage; also check the equipment's noise reduction design, such as the use of sound insulation cotton in the frame and mufflers on the motor, to ensure that the equipment operating noise is ≤85dB, meeting environmental standards.

4. Standardize Contract Signing: Clarify Rights and Responsibilities to Avoid Future Disputes

The contract is the legal basis for protecting user rights. When signing, all terms should be detailed to clarify the rights and responsibilities of both parties and avoid future disputes.

Clearly define equipment configuration and quality standards. The contract should detail key parameters such as the equipment model, specifications, capacity, motor power, core component brands (such as bearings and motors), and materials to prevent manufacturers from cutting corners. At the same time, the equipment quality standards should be clearly defined, requiring the equipment to comply with the GB/T 25709-2010 "Jaw Crusher" national standard, and providing quality certificates and third-party testing reports to ensure that the equipment has no quality problems. The warranty period for the equipment should be agreed upon; the warranty period for core components (eccentric shaft, jaw plate, bearings) is usually no less than 1 year, and the warranty period for the entire machine is no less than 6 months, clearly defining the repair responsibilities and cost allocation during the warranty period.

Detail payment methods and delivery terms. It is recommended to use "installment payments," such as a 30% down payment, 40% payment after the equipment is manufactured and accepted, 20% after installation and commissioning, and the remaining 10% after the warranty period ends, to avoid difficulties in protecting rights if the manufacturer delays delivery or the equipment has quality problems after a single payment. The delivery terms should clearly specify the delivery time, delivery location, transportation method, and cost allocation. It is recommended that the manufacturer be responsible for transportation and that compensation responsibilities for equipment damage during transportation be agreed upon; at the same time, the acceptance process after equipment arrival should be clearly defined, such as requiring the user to accept the goods within 7 working days after arrival, and notifying the manufacturer in writing immediately if any parts are missing or damaged.

Clearly define installation, commissioning, and after-sales service terms. The contract should stipulate that the manufacturer is responsible for free on-site installation and commissioning, clearly defining the installation and commissioning time (e.g., within 10 working days after equipment arrival), personnel allocation, and acceptance standards (e.g., equipment capacity, output particle size, and operational stability must meet the agreed requirements). After-sales service terms should be detailed, such as the manufacturer providing 24-hour after-sales response, sending technical personnel within 48 hours of receiving a fault notification; free replacement of damaged qualified parts during the warranty period, and providing preferential spare parts supply and repair services outside the warranty period; and also stipulating that the manufacturer must provide technical support such as operation training and maintenance manuals.

5. Subsequent Inspection and Acceptance: Ensuring Equipment Meets Procurement Expectations

The inspection and acceptance of equipment after delivery and during the installation and commissioning phase is the last line of defense to ensure that the equipment meets procurement expectations. This must be strictly carriedto out in accordance with the contract and technical standards.

Equipment acceptance upon arrival requires meticulous attention. After the equipment arrives, the user must organize professional personnel to carefully check the main body of the equipment, core components, accessories, tools, instruction manuals, and certificates of conformity against the contract and delivery lists. They should also check for any damage, deformation, or other problems caused during transportation. Particular attention should be paid to checking whether the model and material of the core components, such as bearing brand and jaw plate material, are consistent with the contract. If any problems are found, photos should be taken as evidence, and the manufacturer should be notified in writing to rectify the issues within a specified timeframe. Unauthorized unpacking and installation are strictly prohibited.

Strict control is required during the installation and commissioning phase. When the manufacturer's technical personnel are on-site for installation and commissioning, the user must supervise the entire process to ensure that the installation procedures comply with specifications, including foundation pouring accuracy, equipment levelness, and component connection tightness. During commissioning, both no-load and load tests must be conducted: the no-load test should last at least 2 hours, checking for smooth operation, abnormal noise, and normal bearing temperature; the load test should use actual crushing materials and run for at least 4 hours to verify whether the equipment's capacity, output particle size, and energy consumption meet the contract requirements. If the equipment performance is found to be substandard during commissioning, the manufacturer must be required to adjust or rectify the equipment until it meets the requirements before the acceptance certificate can be signed.

Purchasing a jaw crusher is a high-investment, long-term decision that requires comprehensive consideration of various factors, including self-needs, brand strength, equipment performance, and contract guarantees, to avoid making hasty decisions. During the purchasing process, users should adhere to the principles of "precise selection, quality priority, contract guarantee, and strict acceptance," conducting thorough research, on-site inspections, and detailed contract negotiations to select cost-effective and highly compatible equipment, laying a solid foundation for the efficient and stable operation of the production line. If you have any questions about equipment selection, it is recommended to consult industry experts or experienced manufacturer technicians for professional advice.

Save Time! Get A Detailed Quotation Quickly.