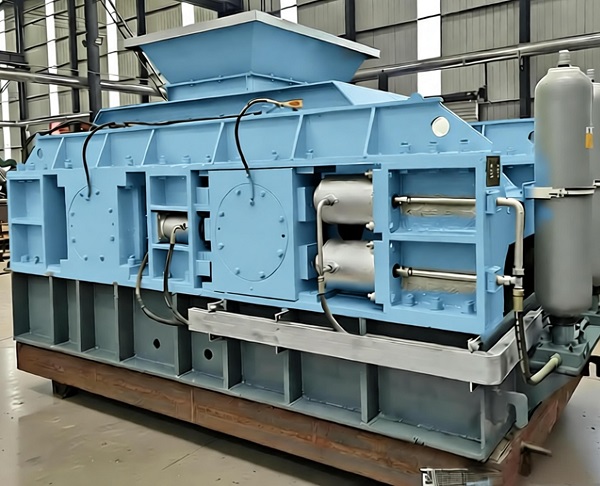

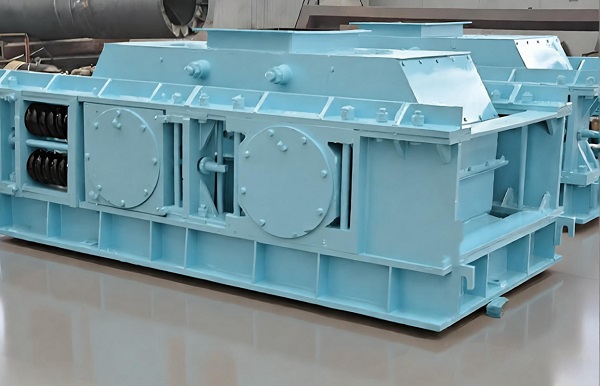

In crushing operations in industries such as mining, building materials, and coal, hydraulic double-roll crushers, as an upgraded version of traditional mechanical double-roll crushers, achieve precise control, efficient operation, and safety assurance in the crushing process by deeply integrating the hydraulic system with the double-roll crushing structure. With two parallel crushing rolls as its core, it relies on hydraulic drive and adjustment technology to provide stable extrusion pressure, completing the crushing of materials with low to medium hardness and even some medium to high hardness. Compared to ordinary mechanical double-roll crushers, hydraulic double-roll crushers have achieved a qualitative leap in pressure control, particle size adjustment, and overload protection, making them particularly suitable for medium-sized production lines with high requirements for crushing precision and production stability. A thorough analysis of its characteristics and advantages provides important guidance for enterprises to optimize crushing processes and improve production efficiency.

A. Core Characteristics of Hydraulic Double-Roll Crusher The core advantage of the hydraulic double-roll crusher stems from its integrated hydraulic system. This system runs through key aspects such as crushing roll adjustment, pressure control, and overload protection, giving it distinct characteristics in structural performance and operating characteristics compared to traditional models. These can be summarized in the following six aspects.

1. Precise Hydraulic Adjustment for More Stable Particle Size Control

The hydraulic double-roll crusher abandons the traditional shim adjustment or manual screw adjustment methods. It achieves linear displacement of the movable rollers through hydraulic cylinders, with real-time position feedback from displacement sensors, resulting in a roller gap adjustment accuracy of 0.01mm. This closed-loop control mode not only accurately sets the target particle size (adjustment range 1-80mm) but also automatically compensates for gap deviations when the feed composition fluctuates. For example, when crushing iron ore containing impurities, if hard particles cause the movable rollers to slightly retract, the hydraulic system can reset the gap within 0.1 seconds, ensuring that the output particle size fluctuation is controlled within ±0.1mm. Furthermore, some high-end models are equipped with a touchscreen control system, allowing operators to directly input particle size parameters for one-button adjustment without stopping the machine. This improves adjustment efficiency by over 80% compared to traditional models, making it particularly suitable for flexible production needs involving multiple batches and variable particle sizes.

2. Adaptive Pressure Control for Significantly Improved Crushing Efficiency

The hydraulic system automatically adjusts the crushing pressure based on the material's hardness. A pressure sensor monitors the roller load in real time. When crushing hard materials (such as quartzite and basalt), the system automatically increases the working pressure to 15-25 MPa to ensure thorough crushing. When processing soft materials (such as limestone and coal gangue), the pressure drops to 5-10 MPa to avoid energy waste. This adaptive characteristic increases the crushing ratio to 8-15, far exceeding the 3-8 of traditional mechanical double-roll crushers, achieving "one-time crushing to standard." Taking a 50t/h production line as an example, the hydraulic double-roll crusher's crushing efficiency per unit time is more than 30% higher than traditional models, and the fine powder content of the crushed material can be controlled below 5%, resulting in more uniform particle shape. Furthermore, the stable pressure output of the hydraulic system ensures uniform stress on the roller surface, avoiding excessive localized wear caused by pressure fluctuations in traditional models and extending roller life by 20%-30%.

For different material characteristics, the hydraulic double-roll crusher also supports quick replacement of various roll surface types. With the hydraulic quick-change device, roll sleeve replacement time can be shortened to less than 1.5 hours, further improving the equipment's material adaptability and production continuity.

3. Intelligent Overload Protection for Enhanced Safety and Reliability The hydraulic system provides a dual overload protection mechanism. When uncrushable foreign objects such as metal blocks or scrap steel are mixed in with the material, the pressure between the rolls instantly exceeds the set threshold. The pressure relay immediately triggers the protection program: firstly, the hydraulic cylinder quickly depressurizes, causing the movable roll to instantly retract 5-10mm, providing a discharge channel for the foreign objects; secondly, the system automatically reduces the main motor speed to avoid motor burnout or gear damage caused by hard impact. After the foreign objects are discharged, the hydraulic system automatically resets and resumes normal operation. The entire process requires no manual intervention, with a response time of less than 0.5 seconds. Compared to the safety pin protection of traditional models (which requires shutdown for safety pin replacement, with an average downtime of over 4 hours), hydraulic protection reduces equipment downtime by more than 95%. Meanwhile, the system is equipped with a triple monitoring device for oil temperature, oil level, and oil pressure. When the hydraulic oil temperature exceeds 55℃ or the oil level is too low, the equipment automatically alarms and reduces its load to prevent damage to the hydraulic system, reducing the overall equipment failure rate by 60%.

Some models also integrate remote diagnostic functions, uploading equipment operating data to the cloud via the Industrial Internet of Things (IIoT). Maintenance personnel can monitor parameters such as pressure curves and temperature changes in real time, providing early warnings of potential faults and enabling "preventive maintenance," further improving equipment reliability.

4. Structural Optimization and Upgrades for More Convenient Operation and Maintenance While retaining the compact advantages of traditional models, the hydraulic double-roll crusher has undergone optimized design of key components. The transmission system adopts a direct drive mode of "motor-hydraulic motor," replacing the traditional gear transmission, reducing mechanical transmission components by more than 60%, and lowering the equipment operating noise to below 75 decibels, 10-15 decibels lower than traditional models. The lubrication system has been upgraded to automatic centralized lubrication. A programmable lubrication pump precisely supplies oil to key components such as bearings and cylinders according to a set cycle, reducing lubricant consumption by 40% and eliminating the problem of omissions during manual lubrication. In terms of maintenance, the hydraulic system adopts a modular design, with components such as the oil tank, oil pump, and filter being independent units. During troubleshooting, modules can be quickly replaced, reducing maintenance time to one-third of traditional models. For example, replacing hydraulic cylinder seals takes only 30 minutes, while maintenance of traditional mechanical adjustment mechanisms typically requires 2-3 hours.

The equipment is also equipped with an online hydraulic oil filtration device, which can filter impurities in the oil in real time, extending the hydraulic oil replacement cycle from the traditional 6 months to 12 months, further reducing maintenance costs and downtime.

5. Strong feed adaptability and outstanding anti-clogging and anti-sticking effect: The hydraulic double-roll crusher adopts a "wide feed inlet + hydraulic floating roller" design. The feed inlet width can reach 1.5-2 times the roller diameter, which can accept blocky materials with a maximum particle size of 5-8 times the initial gap between the rollers. For sticky materials with high moisture content (≤20%) (such as clay and wet coal), the hydraulic system drives the movable rollers to achieve high-frequency micro-amplitude vibration (vibration frequency 10-15Hz), which, combined with anti-stick roller surfaces (such as polyurethane-coated roller surfaces), effectively prevents material from sticking to the roller surface and clogging the crushing chamber. When processing wet coal with a moisture content of 18%, the equipment's clogging rate is only 1/10 of that of traditional mechanical double-roll crushers, and the effective operating rate remains above 98%. Furthermore, the hydraulic pusher device automatically adjusts the feeding speed. When the feed rate is too high, the pusher plate slows down the feeding rhythm to avoid material accumulation; when the feed rate is too low, it accelerates the feeding to ensure the equipment operates at full load and improves energy utilization.

A hydraulically driven grid device installed at the feed inlet automatically clears large pieces of material stuck between the grids, eliminating the need for manual knocking and further improving the equipment's automation level and operational stability.

6. Rational Energy Consumption Distribution, More Economical Operating Costs

Although the hydraulic system increases energy consumption to some extent, the overall energy consumption of the hydraulic double-roll crusher is still 15%-20% lower than that of traditional models through pressure self-adaptation and intelligent control. Its energy-saving advantages are reflected in two aspects: First, the crushing pressure is adjusted on demand, avoiding the energy waste of traditional models that use excessive power for insufficient capacity, with unit product energy consumption as low as 0.5 kWh/t; second, the hydraulic transmission efficiency is over 90%, 15%-20% higher than mechanical gear transmission, reducing energy loss during transmission. Regarding the cost of wear parts, the stable pressure of the hydraulic system ensures uniform roller wear, extending service life by 20%-30%. Combined with wear-resistant roller surfaces that can be repaired by welding (such as high-chromium alloy roller surfaces), the cost of wear parts per ton of material can be controlled below 0.8 yuan, a 25% reduction compared to traditional models. Furthermore, the automated operation of the equipment reduces manual intervention; a 50t/h hydraulic double-roll crusher requires only one operator for 24/7 monitoring, reducing labor costs by more than 50%.

According to industrial data statistics, a hydraulic double-roll crusher with a processing capacity of 50t/h saves 150,000-200,000 yuan in annual comprehensive operating costs (energy consumption + maintenance + labor) compared to a traditional mechanical double-roll crusher. The investment payback period is typically controlled within 1.5-2 years, demonstrating significant economic benefits.

B. Application Advantages of Hydraulic Double-Roll Crusher

Based on the technological upgrade of the hydraulic system, the hydraulic double-roll crusher exhibits a more significant competitive advantage in industrial applications than traditional models. It not only improves production efficiency and product quality but also adapts to more complex operating environments. Its application advantages are mainly reflected in the following five aspects:

1. Expanding Crushing Boundaries, Adapting to Medium-High Hardness Materials

Traditional mechanical double-roll crushers, due to insufficient pressure, can only handle materials with a hardness ≤100MPa. However, the hydraulic double-roll crusher, through a high-pressure output of 15-25MPa, can effectively crush medium-high hardness materials with a hardness ≤200MPa, such as basalt, granite, and iron ore. This expands the application scenarios from the traditional coal and building materials industries to fields such as metal mines and metallurgical slag treatment. In iron ore crushing production lines, hydraulic double-roll crushers can crush iron ore with a particle size of 300mm to below 20mm, increasing crushing efficiency by 25% compared to traditional jaw crushers. The products also exhibit uniform particle shape, reducing energy consumption by 30% for subsequent grinding processes. In metallurgical slag treatment, the equipment can crush water-quenched steel slag to below 10mm, enabling resource utilization of steel slag and increasing processing efficiency by 40% compared to traditional crushing equipment. This expansion of application boundaries makes hydraulic double-roll crushers a versatile crushing device across multiple industries, enhancing the investment value of the equipment.

2. Improving Product Quality and Meeting High-End Production Needs The precise control of the hydraulic system ensures that the discharge particle size deviation of the hydraulic double-roll crusher is controlled within ±0.1mm, far superior to the ±1mm of traditional models. The products exhibit cubic particle shape, with a fine powder content of ≤5% and a reasonable gradation, directly meeting the needs of high-end production. In manufactured sand production, quartz sand crushed by hydraulic double-roll crushers has a particle size concentrated between 0.3-1.2mm, with full particle shape and low porosity. The resulting concrete has a strength more than 20% higher than sand produced by traditional crushing equipment, making it suitable for high-rise buildings, bridges, and other high-end projects. In ceramic raw material processing, the equipment can crush kaolin to below 200 mesh, with uniform particle distribution, controlling the sintering shrinkage rate fluctuation of ceramic blanks within ±0.5%, and increasing the product qualification rate from 85% with traditional equipment to 98%. Furthermore, the stable crushing process reduces over-crushing of materials, improving the finished product recovery rate. In precious metal ore crushing, the recovery rate of precious metals such as gold and silver is 3%-5% higher than with traditional models, significantly improving the economic benefits for enterprises.

For specialized industries requiring precise particle size control, such as the crushing of positive and negative electrode materials for lithium batteries, hydraulic double-roll crushers can achieve customized crushing of materials by setting different pressure and gap parameters through programming, preserving the original properties of the materials and meeting the process requirements of high-end manufacturing.

3. Adaptable to Harsh Working Conditions, Enhanced Operational Stability The hydraulic double-roll crusher features a fully sealed structure. The hydraulic system is equipped with dustproof, waterproof, and corrosion-resistant devices, enabling stable operation in harsh conditions such as high temperatures (-20℃ to 60℃), high humidity, and high dust levels. It is particularly suitable for field operations such as open-pit mines and tunnel construction. In rainy open-pit coal mines, the equipment can operate normally during heavy rain, as the hydraulic system's drainage device promptly removes internal water, preventing component corrosion. In high-temperature desert stone crushing sites, the equipment's hydraulic oil cooling system can control the oil temperature below 55℃, ensuring stable system operation. Furthermore, the heavy-duty frame uses an integral cast steel structure, coupled with a hydraulic buffer device, which effectively absorbs impact loads during the crushing process. In bumpy mobile crushing stations, the equipment's operational stability is improved by more than 50% compared to traditional models, meeting the mobile crushing needs of road construction, emergency rescue, and other similar applications.

In underground crushing operations, the low noise and compact size advantages of hydraulic double-roll crushers are even more prominent. The equipment operates at a noise level below 75 decibels, better meeting the environmental protection requirements for underground operations than traditional crushing equipment. Its compact structure also facilitates installation and commissioning in confined underground spaces.

4. Achieving Intelligent Linkage and Facilitating Digital Production The control system of the hydraulic double-roll crusher can seamlessly integrate with the factory's MES and DCS systems. Through industrial Ethernet, it uploads equipment operating data (such as crushing pressure, roller gap, output particle size, energy consumption, etc.) to the central control room in real time, enabling remote monitoring and data traceability of the production process. Operators can remotely set crushing parameters and start/stop the equipment via a touchscreen in the central control room, eliminating the need for on-site operation and reducing labor intensity and safety risks. In intelligent production lines, the equipment can receive signals from the upstream feeder and automatically adjust the feeding speed and crushing pressure, achieving full-process linkage control of "feeding-crushing-screening". For example, when the screening machine reports that the finished product particle size exceeds the standard, the system automatically adjusts the roller gap; when the feeder detects an increase in the feed rate, the equipment automatically increases the crushing pressure to ensure stable production. Furthermore, the equipment's big data analytics capabilities can optimize crushing parameters using historical operating data, increasing processing efficiency by 10%-15% and reducing energy consumption by 5%-10%, thus helping enterprises achieve digital and intelligent production transformation.

Some high-end models also support AI algorithm optimization, automatically matching optimal pressure and speed parameters by learning the crushing characteristics of different materials, further improving production efficiency and product quality, and providing core equipment support for enterprises to create "unmanned" crushing workshops.

5. Compliant with Environmental Policies, Achieving Green Production

Against the backdrop of increasingly stringent environmental policies, the green and environmentally friendly advantages of hydraulic double-roll crushers are becoming increasingly prominent. In terms of dust control, the equipment adopts a fully enclosed casing and labyrinth seal structure, coupled with a pulse dust removal system, to control the dust concentration in the workshop to below 10mg/m³, far below the national "Integrated Emission Standard for Air Pollutants" (30mg/m³). Regarding noise control, the low vibration characteristics of the hydraulic transmission ensure that the equipment's operating noise is below 75 decibels, meeting workshop noise limits without the need for additional noise reduction equipment. In terms of energy consumption, the unit product's energy consumption is reduced by 15%-20% compared to traditional models, and carbon emissions are reduced by more than 20%, aligning with the "dual-carbon" development goal. Furthermore, the equipment's hydraulic oil can be reused through a filtration and regeneration system, achieving a recovery rate of over 95%, reducing waste oil pollution. Wear parts are made of recyclable wear-resistant alloy materials, realizing resource recycling.

After a building materials company replaced its traditional crushing equipment with a hydraulic double-roll crusher, the dust concentration in its workshop decreased from 60 mg/m³ to 8 mg/m³, and the noise level dropped from 90 decibels to 72 decibels. This resulted in an annual reduction of approximately 800 tons of carbon emissions. The company not only passed environmental protection inspections but also received green production subsidies from the local government, achieving a win-win situation for both economic and environmental benefits.

The hydraulic double-roll crusher, through the deep integration of the hydraulic system and crushing technology, has achieved a leap from "mechanical control" to "precise intelligence." Its precise particle size adjustment, adaptive crushing pressure, reliable overload protection, and advantages such as expanding crushing boundaries, improving product quality, and adapting to harsh working conditions have made it a crucial player in the modern crushing industry. It not only solves the pain points of traditional mechanical double-roll crushers—low efficiency, poor control precision, and high failure rate—but also meets the development needs of high-end production, intelligent linkage, and green environmental protection.

Save Time! Get A Detailed Quotation Quickly.