Preface: The use and maintenance precautions of cone crushers are essential to ensure the safe operation of the equipment, extend its service life, and improve production efficiency. The following are some key use and maintenance precautions:

A. Precautions for the use of cone crushers

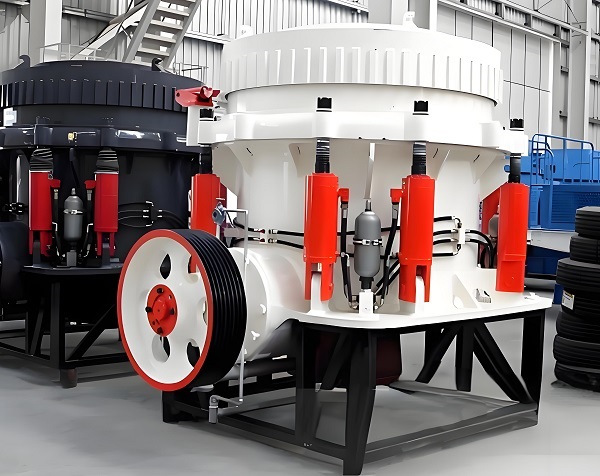

Cone Crusher

1. Pre-start inspection:

Before starting the cone crusher, a series of inspections and preparations are required to ensure that the equipment can operate normally and safely.

Check whether the installation of each component meets the requirements and whether the screws and bolts are loose.

2. Lubrication system inspection:

After starting the oil pump motor, it is necessary to check the working condition of the lubrication system to ensure that the lubrication system works properly. The lubrication system is essential to reduce friction resistance, wear and heat, as well as to protect and extend the service life of the machinery.

3. Feeding precautions:

The cone crusher can only start feeding after running at no load for 1~2 minutes.

The ore feeding position must be accurate, and the ore must be fed in the middle of the cone crusher distribution plate, and cannot be fed directly into the crushing chamber to prevent overloading of the crusher and uneven wear of the liner.

The size of the ore fed should be less than 85% of the size of the equipment feed port to avoid reduced production and component damage.

Pay attention to whether the feeding is normal, especially for ore with high mud content and high moisture content, to prevent the ore from blocking the feeding port.

Cone Crusher

4. Operation monitoring:

When the cone crusher is running, it is necessary to closely monitor its operating sounds, including the sounds of stone breaking, mechanical operation and gear meshing, to ensure that they are stable and without abnormalities.

Check the inside of the machine body and pay attention to whether there is abnormal noise to quickly identify and deal with potential faults.

Pay attention to check the discharge of ore to ensure that the logistics enter and discharge evenly and the discharge port is unobstructed.

5. Stop sequence:

When stopping normally, the feeding should be stopped first, and the ore in the cone crusher should be completely discharged before stopping the main motor and finally stopping the oil pump motor.

B. Maintenance precautions for cone crusher

1. Daily inspection:

Regularly check the various components of the cone crusher, including the motor, bearings, gears, cylinder body, etc., to ensure their normal operation and no looseness.

Check the operation of the cone crusher oil pump frequently to ensure its normal operation.

During the production of cone crushers, the pressure of the locking system and the working condition of the hydraulic station should be checked frequently, and problems should be dealt with in time.

Cone Crusher

2. Cleaning and dust removal: Clean and dust the equipment regularly to keep it clean and tidy.

Clean the discharge port of the cone crusher regularly to avoid equipment blockage and failure caused by impurities accumulation.

3. Lubrication and maintenance: Lubricate and maintain the cone crusher regularly to ensure the normal operation of the equipment's lubrication system.

Replace the applicable lubricating oil and fuel according to seasonal changes, and take necessary antifreeze measures.

4. Replace wear parts: Regularly check the blades, gears and other wearing parts of the cone crusher, and replace the severely worn parts in time to ensure the normal operation of the equipment.

5. Fastener inspection: Regularly check the fasteners of the cone crusher, such as the cylinder body, liner, etc., and tighten or replace them in time if they are loose or worn.

6. Seasonal and transfer maintenance: When performing seasonal maintenance, mainly replace the lubricating oil and fuel of the applicable season, and take additional antifreeze measures, etc.

Before the cone crusher is moved to the construction site, it should be transferred and maintained. The work content can be maintained according to the technical condition of the cone crusher, and anti-corrosion treatment can be carried out if necessary.

PS: The use and maintenance precautions of the cone crusher cover many aspects such as inspection before startup, monitoring during operation, shutdown sequence, and daily maintenance and maintenance. Following these precautions can ensure the safe operation of the equipment, extend its service life and improve production efficiency.

Save Time! Get A Detailed Quotation Quickly.