Impact crusher is a kind of efficient crushing equipment, which plays an important role in many industries. The following is a detailed explanation of the role and working principle of impact crusher:

A. The role of impact crusher

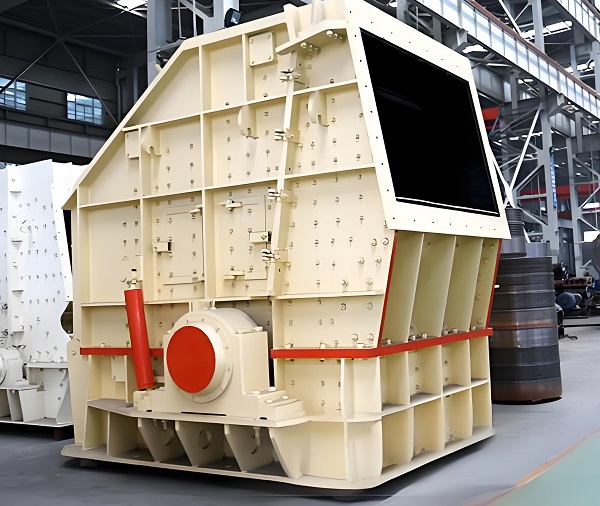

Impact Crusher

Impact crusher is mainly used to process materials with medium hardness and below, such as limestone, quartz, dolomite, iron ore, river pebbles, construction waste, etc. Impact crusher plays a key role in many industries such as mining, construction, roads, railways, bridges, tunnels, water conservancy, chemical industry, etc. It can crush various materials into the required particle size to meet the needs of material crushing in different industries. Specifically:

1. Mining industry: In the mining process, impact crusher is often used to crush ore into smaller particle size for subsequent mineral processing, smelting and other processes. At the same time, it can also process some ores containing impurities to improve the utilization rate of ore.

2. Construction industry: In the construction field, impact crusher is mainly used to process materials such as construction waste and waste concrete. Through crushing, these waste materials can be converted into recycled aggregates for the production of new building materials to achieve the recycling of resources.

3. Highway and railway construction: In the construction of infrastructure such as highways and railways, impact crushers are widely used in processes such as stone processing and roadbed filling. It can crush large pieces of stone into the required particle size and provide high-quality fillers for roadbed filling.

Impact Crusher

4. Water conservancy, chemical industry and other industries: In water conservancy, chemical industry and other industries, impact crushers also play an important role. It can handle various materials with different hardness and provide the required raw materials and fillers for production.

B. Working principle of impact crusher

Impact Crusher

The working principle of impact crusher is to use impact energy to crush materials. Specifically, when the material falls into the machine from the feed port, it will enter the rotation range of the plate hammer connected to the rotor. At this time, the material is impacted by the plate hammer running at a higher speed, and then thrown at high speed along the tangent direction of the plate hammer rotation to the impact plate of the upper support of the machine body, and collides with the impact plate. After the collision, the material returns from the impact plate to the plate hammer rotating nest, and the above process continues to repeat. In this process, the material is repeatedly impacted by the plate hammer and the impact plate, as well as the mutual collision in the crushing chamber, so that the internal structure of the material is destroyed, loosened and broken. Finally, the material crushed into small particles is forced to be discharged in the gap between the plate hammer and the impact plate, becoming the crushed product.

PS: The impact crusher plays an important role in many industries through its unique working principle and efficient crushing performance. Understanding the role and working principle of the impact crusher is of great significance to improving the efficiency of the equipment and the crushing effect.

Save Time! Get A Detailed Quotation Quickly.