With the acceleration of urbanization, the amount of construction waste generated has exploded. Statistics show that my country generates over 2 billion tons of construction waste annually, with a resource utilization rate of less than 30%. This not only occupies a large amount of land resources but also easily leads to environmental problems such as soil pollution and dust pollution. Impact crushers, with their large crushing ratio, excellent product particle shape, and strong adaptability, have become the core equipment for the resource-based treatment of construction waste, playing an irreplaceable role in the crushing and processing of materials such as concrete blocks, bricks, and waste mortar. This article will delve into the application scenarios, technological advantages, process configurations, and optimization directions of impact crushers in construction waste treatment, providing practical references for the industry's green development.

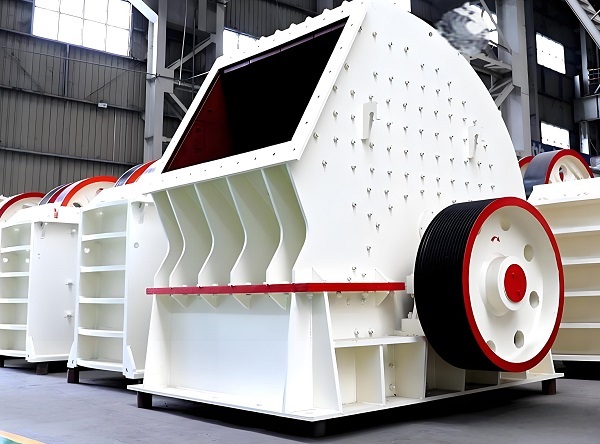

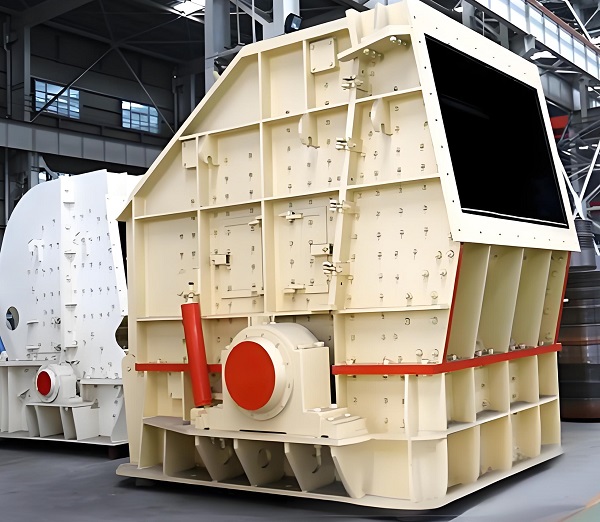

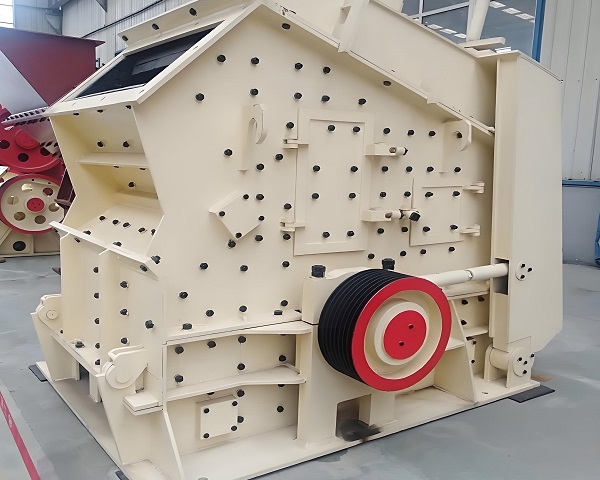

Construction waste has a complex composition, mainly including concrete blocks, reinforcing bars, bricks, ceramic fragments, and waste wood. It is characterized by uneven material hardness, irregular particle shape, and high impurity content (usually 5%-15%), placing high demands on the wear resistance, impact resistance, and adaptability of crushing equipment. The impact crusher employs the "impact crushing" principle. A high-speed rotating rotor drives hammer plates to impact the material, and multiple collisions between the impact plates and the material achieve crushing. This structural design gives it three major advantages:

Firstly, a large crushing ratio and excellent particle shape. The impact crusher's crushing ratio can reach 10-30, far exceeding that of traditional jaw crushers. It can directly crush large pieces of construction waste (maximum feed size up to 800mm) into recycled aggregate of 5-31.5mm, with a cubic shape and a needle-like/flaky content of less than 10%, meeting the requirements for recycled concrete. The impact crusher meets several key requirements for construction waste treatment. First, it offers strong adaptability and impact resistance. The high-strength hammers and wear-resistant liners withstand the impact of hard materials in construction waste, while also providing flexible adjustment. By adjusting the gap between the impact plate and the rotor, different particle sizes can be achieved. Second, it boasts outstanding impurity handling capabilities. For metal impurities such as steel bars and wires mixed in construction waste, the impact force of the hammers separates the metal from the aggregate. Subsequent magnetic separation allows for efficient sorting, preventing damage to the equipment from impurities.

A. Core Application Scenarios of Impact Crusher in Construction Waste Treatment

1. Recycled Aggregate Production

Recycled aggregate is the core product of construction waste resource recovery. The impact crusher, through a combination of coarse crushing and medium/fine crushing, can convert construction waste into recycled aggregates of different specifications. For example, in urban demolition waste treatment projects, concrete blocks (≤300mm in diameter) coarsely crushed by a jaw crusher are fed into an impact crusher for medium and fine crushing. The resulting 5-25mm recycled coarse aggregate can be used to prepare recycled concrete and recycled permeable bricks, while the 0-5mm recycled fine aggregate can replace river sand in plastering mortar and subbase materials. A construction waste treatment plant uses a PF-1315 impact crusher, processing 800-1000 tons of construction waste per day, with a recycled aggregate qualification rate of over 95%, saving over 300,000 tons of natural sand and gravel resources annually.

2. Mobile Crushing Station Operation To address the dispersed nature and high transportation costs of construction waste, impact crushers are often integrated with jaw crushers, vibrating screens, feeders, and other equipment to form mobile crushing stations. Mobile crushing stations can be driven directly to demolition sites, achieving "on-site crushing and on-site utilization" of construction waste, significantly reducing transportation costs and dust pollution. For example, in urban renewal projects, mobile impact crushers can crush demolition waste into recycled aggregate in real time, which can be directly used for on-site road subbase and foundation backfilling, improving resource utilization and shortening the construction cycle. These devices are typically equipped with diesel generators to adapt to operating scenarios without power grid coverage, and use enclosed enclosures and spray dust suppression systems to meet environmental emission requirements.

3. Special Construction Waste Processing For special construction waste containing high-strength concrete, granite, and other hard components, ordinary crushing equipment is prone to problems such as material jamming and rapid wear. Impact crushers, by optimizing the hammer material (e.g., using high-manganese steel or high-chromium alloy) and rotor speed, can achieve highly efficient crushing. For example, in bridge demolition waste processing, impact crushers can crush concrete blocks with a strength grade of C60 or higher, and the resulting recycled aggregate can be used to make high-strength recycled concrete components. Simultaneously, for construction waste containing brittle materials such as ceramics and glass, the impact crushing method of impact crushers can reduce excessive material pulverization and improve aggregate recovery rates.

B. Process Optimization and Technological Upgrading of Impact Crusher in Construction Waste Treatment

1. Process Configuration Optimization

To improve processing efficiency and product quality, construction waste treatment lines typically employ an integrated process of "pre-treatment + crushing + screening + sorting." In the pre-treatment stage, large impurities such as wood and plastic are removed through manual sorting or drum screens. The crushing stage uses a two-stage crushing process of "jaw crusher + impact crusher," with the jaw crusher handling coarse crushing and volume reduction, and the impact crusher handling medium and fine crushing and shaping. In the screening stage, multi-layer vibrating screens are used to grade recycled aggregates of different specifications. In the sorting stage, magnetic separation, air separation, and other equipment remove metals and lightweight impurities. Furthermore, some high-end production lines have introduced intelligent sorting equipment, using AI visual recognition technology to accurately separate materials of different materials, further improving the purity of recycled aggregates.

2. Equipment Technology Upgrades

To adapt to the environmental protection and high-efficiency requirements of construction waste treatment, the impact crusher undergoes continuous technological iteration: First, wear-resistant components are upgraded, using composite wear-resistant materials for the hammers and impact plates, extending their service life by 30%-50% compared to traditional materials, reducing replacement frequency and maintenance costs; second, intelligent control is implemented, equipped with a PLC control system and a touch screen operating interface, enabling real-time monitoring of equipment operating parameters (such as rotor speed, feed rate, and discharge particle size), achieving automatic adjustment and fault warning; third, enhanced environmental performance is achieved, with the addition of high-efficiency dust removal devices and noise reduction equipment, controlling dust emission concentration below 10mg/m³ and noise below 85dB(A), meeting the requirements of the "Integrated Emission Standard for Air Pollutants"; fourth, energy-saving renovation is carried out, adopting a variable frequency motor and optimized rotor structure, reducing unit energy consumption by 15%-20% compared to traditional equipment, aligning with the green and low-carbon development trend.

3. Common Problems and Solutions

In practical applications, impact crushers are prone to problems such as excessively rapid hammer wear, material blockage, and excessively large product particle size. To address hammer wear, optimization of the feed particle size (controlling the maximum feed particle size to no more than 80% of the equipment's rated value) and selection of hammers made of suitable materials (high-chromium alloy hammers for hard materials, and high-manganese steel hammers for mixed materials) can be implemented. For material blockage, an iron removal device and pre-screening equipment can be installed at the feed inlet to prevent large impurities from entering the crushing chamber, while regularly cleaning the accumulated material inside the equipment. For excessively large product particles, precise particle control can be achieved by reducing the gap between the impact plate and the rotor, increasing the rotor speed, or increasing the number of crushing stages (using a two-stage crushing process of "impact crusher + impact crusher").

With the advancement of "dual carbon" goals and tightening environmental policies, the resource utilization of construction waste has become an inevitable trend. As a core piece of equipment, the impact crusher is experiencing continuous market demand growth. Future development will focus on three main directions: First, larger scale and higher efficiency, developing impact crushers with larger processing capacities (over 2000 tons per day) and higher crushing efficiency to adapt to large-scale construction waste treatment projects; second, intelligent and digital, combining IoT and big data technologies to achieve remote equipment monitoring, fault prediction, and operation and maintenance management, improving the automation level of production lines; and third, multi-functional integration, developing composite equipment integrating crushing, screening, sorting, and dust removal to further simplify the process and reduce investment costs.

With its unique structural advantages and adaptability, the impact crusher plays a core role in the resource-based treatment of construction waste. It not only effectively solves the pollution problem of construction waste but also turns waste into treasure, providing a sustainable alternative resource for the building materials industry. With continuous technological upgrades and process optimization, impact crushers will play an even greater role in recycled aggregate production, mobile operations, and special construction waste treatment scenarios. In the future, enterprises need to further strengthen equipment research and development and process innovation, improve product quality and environmental performance, and promote the development of the construction waste recycling industry towards high efficiency, greenness and intelligence, so as to provide strong support for building a resource-saving and environmentally friendly society.

Save Time! Get A Detailed Quotation Quickly.