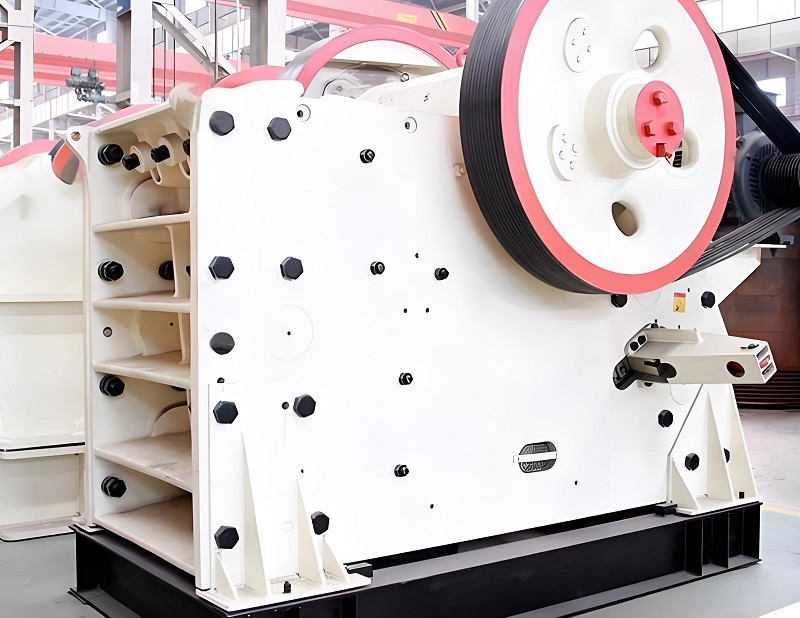

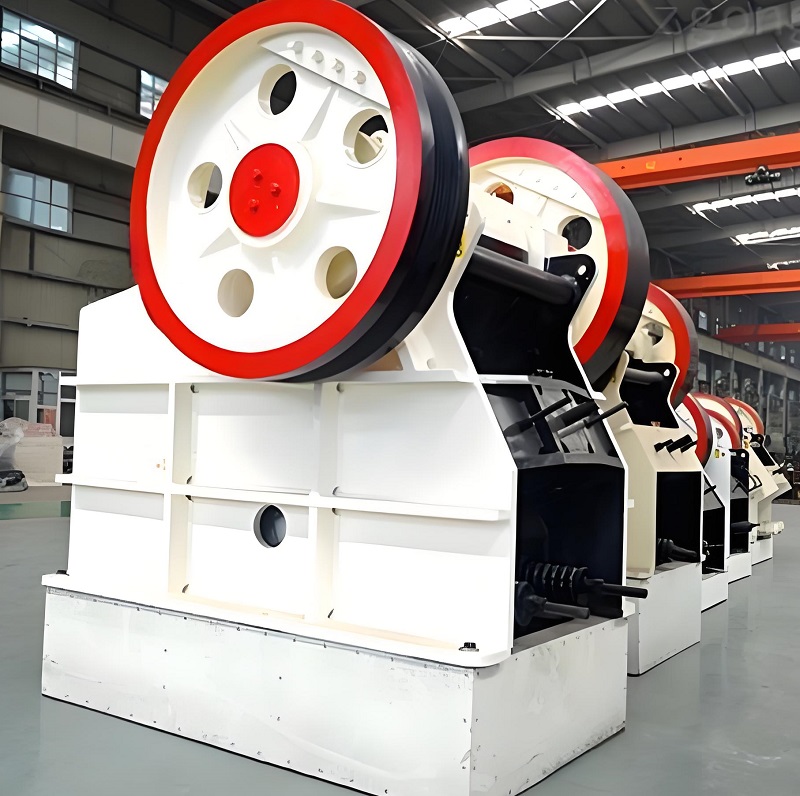

As a core piece of equipment in the field of coarse crushing of solid waste, jaw crushers, relying on the working principle of compression and splitting, possess the advantages of large feed size, robust structure, and wear resistance. They are suitable for the disposal of various high-hardness, large-sized solid wastes, and are a key piece of equipment for waste reduction and resource recovery. Their suitability is determined by the hardness and viscosity of the material, primarily suitable for hard and medium-to-low hardness solid waste, but not suitable for flexible, easily entangled materials. This article, combining equipment performance, details the types of waste that can be crushed by jaw crushers, analyzes suitable scenarios and pretreatment key points, providing a reference for the crushing and disposal of various types of waste.

Jaw crushers, with their crushing principle of compression and splitting, and characteristics of large feed size, robust structure, and wear resistance, have become a core piece of equipment in coarse crushing operations. They are widely used in the crushing and processing of various solid wastes, especially adept at handling high-hardness, large-sized waste, and are suitable for various industrial and domestic waste disposal scenarios, contributing to waste resource recovery and utilization. The types of waste that can be crushed need to be classified based on equipment performance, primarily suitable for hard and medium-to-low hardness solid waste, and not suitable for highly viscous, easily entangled flexible waste. The following details the types of suitable waste and application key points.

Construction waste is one of the main materials processed by jaw crushers. This type of waste mainly consists of hard materials, which aligns with the coarse crushing advantages of jaw crushers, and is also a key area in current waste resource utilization. Concrete blocks, cement blocks, brick and tile fragments, asphalt waste, and demolition waste generated during urban demolition, old building renovation, road repairs, and construction sites can all be initially crushed by jaw crush crushers. After crushing, concrete blocks and cement blocks, combined with a magnetic separator to remove the small amount of mixed rebar impurities, produce coarse aggregate that can be directly used for roadbed backfilling. After connecting to secondary crushing equipment, it can also be processed into recycled fine aggregate for the production of recycled bricks, recycled concrete, and other building materials, achieving resource recycling. Crushed brick and tile fragments and asphalt waste can be used for foundation filling and road subgrade paving, effectively reducing the amount of construction waste sent to landfills. When processing this type of waste, mobile jaw crushing stations can achieve on-site crushing, significantly reducing material transportation costs, and are suitable for scenarios with frequent site changes, such as demolition sites. In industrial solid waste, most hard waste materials can be processed by jaw crushers, especially those high-hardness waste residues generated in mining, metallurgy, and chemical industries. Waste rock, mining scraps, tunnel slag, foundation pit stone, and mine tailings generated during mining and processing, whether hard rock tailings such as granite and basalt, or medium-to-low hardness waste rock like limestone, can all be coarsely crushed by jaw crushers. The crushed material can then be reused as aggregate raw materials, improving the utilization rate of mining resources. Slag, mine waste, and sintered ore waste from the metallurgical industry, which are high in hardness and wear-resistant, can be effectively crushed by jaw crushers with their high-strength jaw plates and optimized cavity design. The crushed material can then be used to manufacture building materials, roadbed fillers, etc., achieving the reduction and disposal of industrial waste residue. In addition, chemical raw material waste such as phosphate rock and pyrite from the chemical industry, as well as discarded refractory furnace linings, can also be crushed and recycled using jaw crushers.

Some medium-to-low hardness domestic and other solid waste can be processed by jaw crushers after pre-treatment. Coal gangue and waste coal generated during coal mining and processing have moderate hardness, and jaw crushers can quickly perform coarse crushing. The crushed coal gangue can be used for power generation and brick making, and the waste coal can be reused for combustion to generate electricity, improving resource recovery efficiency. Glass and ceramic waste generated in daily life are hard and non-sticky. After sorting and removing impurities, they can be crushed by jaw crushers and used to prepare recycled aggregates or as building auxiliary materials, reducing the accumulation of domestic solid waste. Furthermore, large components such as discarded reinforced concrete precast slabs and building columns, even those with bent reinforcing bars at the ends, can be dismantled by jaw crushers through compression crushing, while simultaneously cutting off small reinforcing bars, facilitating subsequent iron removal and sorting, thus solving the problem of disposing of large components. Jaw crushers are suitable for crushing waste materials provided the material hardness is ≤9 on the Mohs scale. They can handle large materials with a feed size of over 1000mm, achieving a crushing ratio of over 9, meeting the coarse crushing needs of various scenarios. However, it's important to note that some materials require pre-treatment, and there are specific types of materials that are not suitable. When processing waste containing a large amount of metal impurities, a magnetic separator is required to prevent rebar, iron blocks, and other impurities from jamming the crushing chamber and damaging the jaw plates; the material moisture content should ideally be controlled within 20%. High-moisture, cohesive materials such as wet mud and high-moisture coal gangue require pre-screening or drying to prevent clogging and maintain crushing efficiency.

It's crucial to understand that jaw crushers are not suitable for flexible, highly viscous waste materials such as plastics, rubber, wood, textiles, and food waste. These types of waste can easily entangle the eccentric shaft, movable jaw, and other core components of the equipment, leading to jamming and malfunctions. They also cannot be effectively broken down through compression crushing. These materials must be removed from the waste stream using sorting equipment before crushing to ensure smooth and efficient operation.

Jaw crushers are primarily suitable for various hard and medium-to-low hardness solid waste materials. They are mainly used for the coarse crushing of construction waste, industrial waste residue, and mining tailings. Through scientific pre-treatment and supporting equipment, they can achieve waste resource recovery and contribute to environmentally friendly disposal. Their suitability depends primarily on material hardness, moisture content, and impurity content. Proper selection of materials to be crushed and effective pre-treatment can maximize equipment crushing efficiency and reduce disposal costs.

Jaw crushers focus on the coarse crushing of hard and medium-to-low hardness solid waste, primarily suitable for construction waste, industrial waste residue, mining tailings, and some pre-treated municipal solid waste. With their stable crushing performance, they contribute to the resource recovery of various types of waste, reducing the environmental pressure caused by landfilling and incineration. Strict control of material suitability boundaries, removal of flexible and highly viscous materials, and proper pre-treatment such as impurity removal and moisture control are essential to maximize equipment efficiency. Their application aligns with environmental disposal needs and enables resource recycling, making them highly practical for various waste treatment scenarios.

Save Time! Get A Detailed Quotation Quickly.