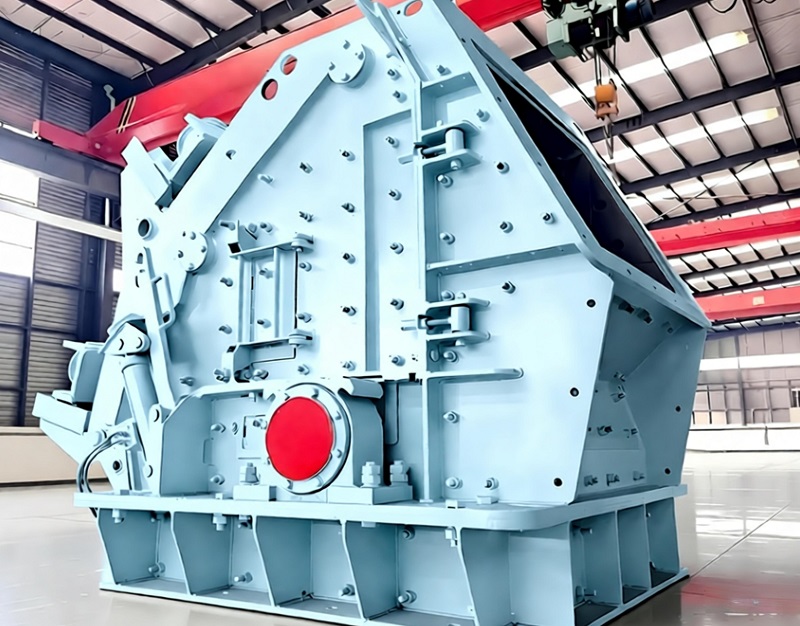

In many fields such as mining, aggregate processing, and road construction, crushing equipment, as core processing equipment, directly determines production efficiency, product quality, and overall costs. Impact crushers, with their unique structural design and crushing principle, demonstrate numerous irreplaceable advantages compared to traditional equipment such as jaw crushers and cone crushers, making them the preferred equipment for medium and fine crushing operations. This article will comprehensively analyze the core crushing advantages of impact crushers from multiple dimensions, including crushing efficiency, product quality, application range, operation and maintenance, and energy saving and environmental protection, providing a reference for professionals in related industries when choosing crushing equipment.

1. Unique Crushing Principle for Superior Crushing Efficiency Compared to Traditional Equipment

Impact crushers utilize the "impact crushing" principle. A high-speed rotating rotor drives the hammer plates to violently impact the material. Simultaneously, the material undergoes multiple collisions, rebounds, and crushing between the hammer plates and the impact plates, and between the material particles themselves, ultimately achieving the desired particle size. This unique crushing method, compared to the "compression crushing" of jaw crushers and the "rolling crushing" of cone crushers, offers significant advantages in crushing efficiency.

On the one hand, the impact crushing force is more concentrated and instantaneous, quickly destroying the internal structure of the material, especially for medium-hard and brittle materials, resulting in significantly improved crushing efficiency. Data shows that when processing common materials such as limestone and granite, the throughput of an impact crusher per unit time is 30%-50% higher than that of a jaw crusher of the same specifications, greatly improving the overall efficiency of the production line. On the other hand, the crushing chamber of the impact crusher adopts an open design, making it less prone to clogging after the material enters the crushing chamber. The material's falling path during the crushing process is also smoother, effectively reducing downtime caused by material accumulation. In addition, the rotor speed of the equipment can be flexibly adjusted according to material characteristics and crushing requirements. By optimizing the speed parameters, crushing efficiency can be further improved, achieving precise capacity matching.

2. Excellent Product Particle Shape, Meeting High-End Building Material Quality Requirements

In fields such as building aggregates and road construction, the particle shape of the material directly affects the performance of the final product. For example, aggregates used in highways and high-speed railways have extremely high requirements for the content of flaky and elongated particles and the uniformity of particle size distribution. Impact crushers produce products that precisely meet these high-end demands, which is one of their core advantages.

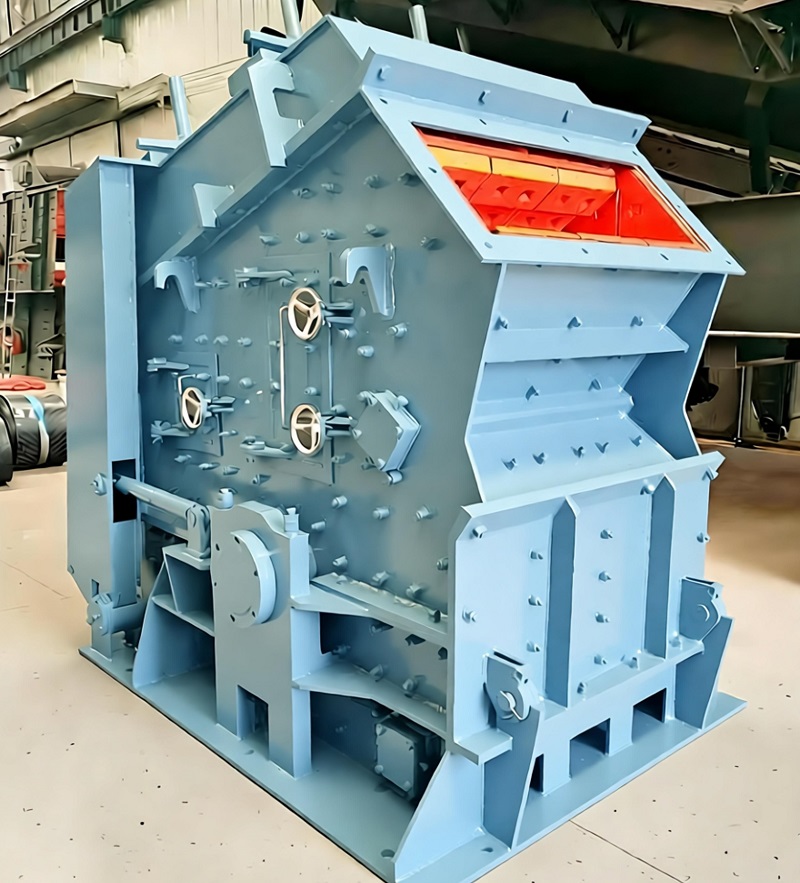

Because the material undergoes multiple impacts and collisions during the crushing process, the particle shape gradually becomes rounder and more regular, resulting in a very low content of flaky and elongated particles, usually below 10%, far lower than the 20%-30% produced by equipment such as jaw crushers. At the same time, impact crushing creates a more reasonable particle size distribution, with uniform distribution of coarse, medium, and fine particles, reducing the workload of subsequent screening processes. Furthermore, the product has a higher bulk density, which improves the strength and durability of concrete when used in concrete mixing. Taking the production of crushed stone for construction as an example, aggregates processed by impact crushers can reduce cement consumption by 5%-10% in concrete mixes, lowering production costs and improving the quality of concrete products. In addition, impact crushers can precisely control the output particle size by adjusting the gap between the impact plate and the hammer, achieving multi-stage adjustment from coarse crushing to fine crushing and ultra-fine crushing, meeting the diverse needs of different industries for material particle size and offering a wider range of applications.

3. Wide range of applicable materials and stronger crushing adaptability

Impact crushers have extremely strong material adaptability and can process a variety of materials from soft to medium-hard, including limestone, dolomite, granite, basalt, iron ore, coal, gypsum, and shale, and are widely used in mining, building materials, chemical, coal, metallurgy, and other industries. Compared to jaw crushers, which are more suitable for coarse crushing of hard rock, and cone crushers, which mainly handle medium and fine crushing of hard rock, impact crushers offer more flexible application scenarios.

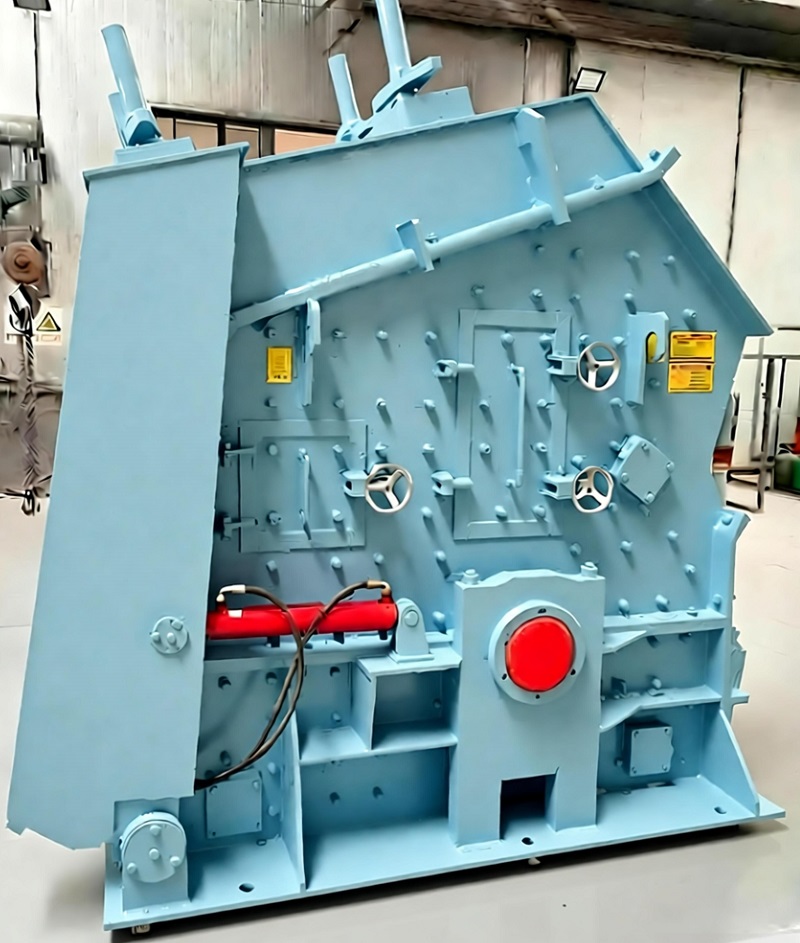

For materials with lower hardness (such as limestone and gypsum), impact crushers can achieve efficient crushing with less equipment wear; for materials with moderate hardness (such as granite and basalt), by using high-wear-resistant materials for the hammer and impact plate, stable crushing performance and a longer service life can still be maintained. Furthermore, impact crushers can handle materials containing a certain amount of moisture. Due to their open crushing chamber design and impact crushing principle, the moisture in the material does not cause equipment blockage. In contrast, jaw crushers and cone crushers are highly susceptible to material sticking to the chamber walls and clogging the feed opening when processing high-moisture materials. At the same time, for materials containing impurities (such as metal blocks), the impact crusher's safety device effectively protects the core components of the equipment. When unbreakable objects such as metal blocks enter the crushing chamber, the safety pin automatically breaks, the impact plate retracts, allowing the unbreakable object to be discharged, preventing damage to the equipment due to overload, further enhancing the equipment's adaptability and operational stability.

4. Reasonable structural design, convenient and efficient operation and maintenance

The structural design of the impact crusher follows the principles of "simplicity, practicality, and ease of maintenance." Compared to the structurally complex cone crusher, its operation and maintenance difficulty are significantly reduced, effectively reducing equipment downtime and lowering operating and maintenance costs.

In terms of structural composition, the impact crusher mainly consists of a frame, rotor, hammer plates, impact plates, adjustment device, and safety device. The number of components is small and the layout is reasonable, making it easy for operators to quickly familiarize themselves with the equipment structure and working principle. In terms of operation, the equipment adopts an intelligent control system. Operators can precisely adjust parameters such as feed rate, rotor speed, and discharge gap through the control console, achieving automated operation without extensive manual intervention, reducing labor costs and operational difficulty. In terms of maintenance, the wear parts of the impact crusher (such as hammer plates and impact plates) are easy to replace. Some models use a hydraulic opening device, which can quickly open the casing to replace wear parts, shortening the replacement time by more than 50% compared to traditional equipment; at the same time, the equipment's lubrication system is reasonably designed, facilitating regular addition of lubricating oil, reducing component wear, and extending the service life of the equipment. In addition, fault diagnosis of the equipment is relatively simple. By observing the equipment's operating sound, vibration frequency, and discharge situation, the type of fault can be quickly determined and repaired, further improving the efficiency of equipment operation and maintenance.

5. Outstanding energy-saving and environmentally friendly performance, consistent with the concept of green production

Against the backdrop of increasingly stringent environmental protection policies, the energy-saving and environmentally friendly performance of crushing equipment has become an important factor for enterprises when choosing equipment. Impact crushers excel in energy consumption control and pollutant emissions, aligning with the current development concept of green production.

In terms of energy consumption, due to the impact crushing principle, impact crushers have high energy utilization efficiency during material crushing, and the energy consumption per unit of product is far lower than that of traditional crushing equipment. Data shows that for processing the same amount of limestone, the unit energy consumption of an impact crusher is 20%-30% lower than that of a jaw crusher and 15%-25% lower than that of a cone crusher, significantly reducing the company's energy costs. In terms of noise control, the equipment adopts noise reduction designs such as sound insulation covers and vibration damping devices, and the operating noise level can be controlled below 85dB, far lower than the 100dB or more of traditional crushing equipment, effectively improving the working environment. In terms of dust control, the feed and discharge ports of the impact crusher are equipped with sealing devices and dust removal equipment, which can effectively reduce dust leakage, and the dust emission concentration meets relevant national standards; at the same time, the amount of dust generated by material collision during the crushing process is less, further reducing environmental pollution. In addition, some new impact crushers use recyclable wear-resistant parts, reducing waste emissions and meeting the requirements of circular economy development.

6. Significant Comprehensive Cost Advantages, Enhancing Corporate Economic Benefits

From a long-term production perspective, impact crushers can bring significant comprehensive cost advantages to enterprises, mainly reflected in equipment procurement costs, operating costs, maintenance costs, and product added value.

In terms of equipment procurement costs, impact crushers of the same specifications are cheaper than cone crushers, and they combine coarse crushing, medium crushing, and fine crushing functions, which can replace multiple traditional crushing equipment in some scenarios, reducing the company's equipment procurement investment. In terms of operating costs, as mentioned above, impact crushers have low unit energy consumption and high automation, which can reduce energy costs and labor costs. In terms of maintenance costs, the wear parts of the equipment have a long service life, are easy to replace, and have low costs. At the same time, the failure rate is low, and the maintenance costs are far lower than traditional equipment. In terms of product added value, because the products produced by impact crushers have excellent particle shape and reasonable gradation, the product added value is higher, allowing them to be sold at a higher price, increasing the company's sales revenue. Overall, impact crushers can help companies significantly reduce comprehensive production costs and improve product competitiveness and economic benefits. Impact crushers, with their high crushing efficiency, excellent product quality, wide material adaptability, convenient operation and maintenance, outstanding energy-saving and environmentally friendly performance, and significant overall cost advantages, demonstrate irreplaceable core competitiveness in various fields such as mining, construction aggregate processing, and road construction. With continuous technological advancements, impact crushers will develop towards intelligence, larger scale, and greater energy efficiency and environmental friendliness, further enhancing their crushing performance and scope of application. For companies in related industries, choosing impact crushers as their core crushing equipment can not only improve production efficiency and product quality but also reduce overall costs, achieving green and sustainable development and giving them a competitive edge in the fierce market competition.

Save Time! Get A Detailed Quotation Quickly.