Construction waste is complex in composition (including concrete blocks, bricks, steel bars, waste wood, etc.), with uneven particle size and strong dispersion, placing multiple demands on the wear resistance, impact resistance, flexibility, and environmental friendliness of crushing equipment. Currently, the commonly used construction waste crushers in the industry mainly include five categories: jaw crushers, impact crushers, hammer crushers, cone crushers, and mobile crushing plants. Each type of equipment, with its unique structural design and functional advantages, is suitable for construction waste processing needs of different scales and working conditions. This article will systematically analyze the core characteristics, application scenarios, and selection points of various types of equipment, providing technical support for construction waste resource utilization projects.

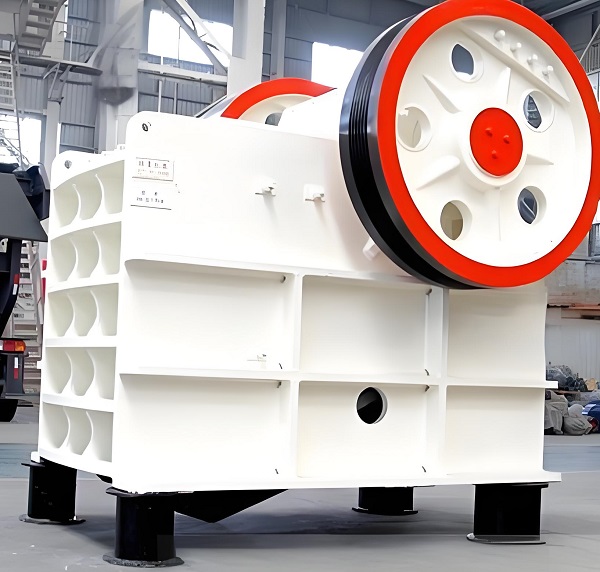

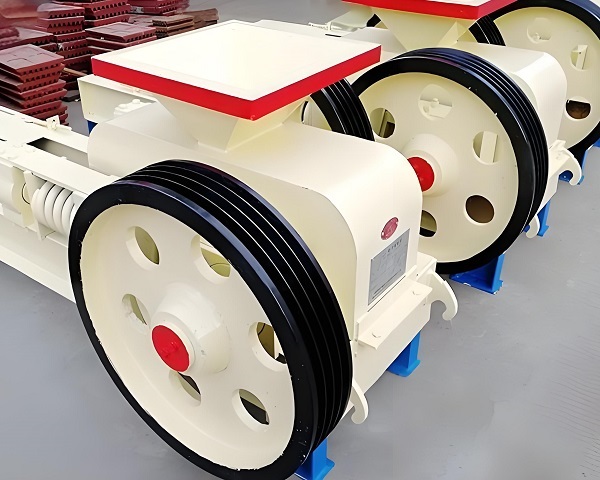

1. Jaw Crusher: Core Equipment for Coarse Crushing of Construction Waste

As a traditional crushing equipment, the jaw crusher is the core of the "first process" in the construction waste processing line. It mainly undertakes the coarse crushing task, crushing large pieces of construction waste (maximum feed particle size up to 1500mm) to below 300mm, laying the foundation for subsequent medium and fine crushing processes.

Its working principle is "compression crushing." Through the periodic opening and closing of the moving and fixed jaws, a compressive force is applied to the material to achieve crushing. It has a simple structure and strong stability, making it particularly suitable for processing construction waste with high hardness (such as high-strength concrete blocks and granite fragments). In construction waste processing, the core advantages of the jaw crusher are threefold: First, outstanding wear resistance; the jaw plates are made of high-manganese steel, which can withstand the impact and wear of hard particles in construction waste, with a service life of 6-12 months. Second, strong overload resistance; the equipment has strong compressive strength to handle large impurities mixed in construction waste, and is less prone to jamming and downtime. Third, low operating costs; the simple structure leads to convenient maintenance. Routine maintenance only requires checking jaw plate wear, tightening bolts, and the lubrication system, with maintenance costs approximately 60%-70% of similar equipment.

Typical application scenarios include fixed production lines in large-scale construction waste treatment plants. For example, a city's construction waste recycling industrial park uses a PE-900×1200 jaw crusher as the primary crushing equipment, processing over 2000 tons of demolition waste per day. The crushed material has a uniform particle size, providing high-quality feed for subsequent impact crushers. The overall production line achieves a 95% qualified rate for recycled aggregate. However, it should be noted that jaw crushers produce products with poor particle shape (approximately 15%-20% needle-like and flaky content), and are only suitable for primary crushing, requiring subsequent shaping equipment.

2. Impact Crusher: Preferred for Fine Crushing and Shaping in Construction Waste

The impact crusher uses "impact crushing" as its core principle. A high-speed rotating rotor drives hammers to impact the material, and multiple collisions between the impact plates and the material achieve crushing. It is the core equipment for fine crushing and aggregate shaping in construction waste, further crushing the coarsely crushed material to a recycled aggregate size of 5-31.5mm.

Compared to other equipment, impact crushers have three core advantages in construction waste processing: First, they have a large crushing ratio (up to 10-30), enabling them to complete medium and fine crushing operations in a single pass, simplifying the process. For example, processing concrete blocks smaller than 300mm can directly produce recycled coarse aggregate smaller than 20mm. Second, they produce excellent particle shape; impact crushing causes materials to break along natural fissures, resulting in a high cubic content (needle-like and flaky content <10%), meeting the requirements for high-end building materials such as recycled concrete and permeable bricks. Third, they have strong impurity handling capabilities; the high-strength impact of the hammers separates metallic impurities such as reinforcing bars and wires from the aggregate, facilitating subsequent magnetic separation.

In terms of application scenarios, impact crushers are suitable for both stationary production lines and can be integrated into mobile crushing stations. In a certain urban renewal project, a PF-1520 impact crusher was used to process demolition waste, with a daily processing capacity of 800 tons. The produced recycled aggregate was used to prepare C30 recycled concrete. Testing showed that the aggregate crushing value, mud content, and other indicators all met the standard of "Recycled Aggregate for Concrete" (GB/T 25177-2010). Its limitation lies in the rapid wear of the hammer plates when processing high-hardness materials; therefore, high-chromium alloy wear-resistant hammer plates must be selected to extend service life.

3. Hammer Crusher:

An Economical Choice for Small and Medium-Sized Construction Waste Processing Hammer crushers use high-speed rotating hammers to impact and crush materials. With a simple structure and low cost, they are the preferred equipment for small and medium-sized construction waste processing projects (daily processing capacity of 100-500 tons), especially suitable for decentralized construction waste processing scenarios in towns and counties. Its core advantages lie in its economy and flexibility: First, low equipment investment; for the same processing capacity, the price of a hammer crusher is only 50%-70% of that of an impact crusher, and the procurement cost of a small mobile hammer crushing station can be controlled at 500,000-800,000 yuan. Second, convenient maintenance; core components only include hammers and screen plates, and replacing a set of hammers only takes 2-3 hours, requiring no professional technicians for daily maintenance. Third, integrated crushing; the product particle size (5-30mm) can be directly controlled by changing the screen plate, eliminating the need for additional shaping equipment. For example, when processing rural demolition waste, it can directly produce aggregate for road subbase.

A township construction waste treatment station uses a PCZ-1210 heavy hammer crusher, processing 200 tons of construction waste per day, crushing waste concrete and bricks into 10-20mm recycled aggregate for paving rural road base layers. The processing cost is only 1/3 of the traditional landfill method, saving approximately 5 mu of land resources annually. It should be noted that hammer crushers are not suitable for processing materials with a hardness >150MPa, and the hammers wear out quickly, requiring frequent replacement when processing high-grade concrete.

4. Cone Crusher: Fine Crushing Equipment for High-Hardness Construction Waste

The cone crusher adopts the principle of "layered crushing," compressing materials through the relative movement of the moving and fixed cones. It is suitable for processing construction waste with high hardness (such as mixed waste containing granite and basalt), primarily undertaking medium and fine crushing tasks, producing high-precision, high-purity recycled aggregate.

In construction waste processing, the core advantages of the cone crusher are high crushing efficiency and uniform product particle size. The discharge port gap can be precisely controlled (error ±0.1mm) through a hydraulic adjustment system, resulting in small aggregate particle size deviations. It is suitable for scenarios with high product quality requirements (such as recycled ready-mixed concrete and high-end building materials). Furthermore, the equipment adopts a closed crushing chamber design, resulting in low dust emissions, and with the addition of a dust removal system, it can meet strict environmental protection requirements. A large building materials company uses an HST-315 cone crusher to process construction waste containing high-strength concrete, with a daily processing capacity of 1200 tons. The crushing value of the produced 5-25mm recycled aggregate is ≤10%, successfully replacing natural aggregate in the production of precast components.

However, its limitations are also obvious: high equipment investment (1.5-2 times the price of an impact crusher for the same processing capacity), high maintenance technical requirements, and strict requirements on feed particle size (must be controlled below 300mm). It is more suitable for large-scale construction waste processing projects, and is rarely used in small and medium-sized projects.

5. Mobile Crushing Station: An Integrated Solution for On-Site Construction Waste Processing

A mobile crushing station is not a single type of equipment, but rather integrates core crushing equipment such as jaw crushers, impact crushers, and hammer crushers with feeders, vibrating screens, conveyor belts, and dust removal systems onto a mobile chassis (wheel-driven or tracked). It can achieve "on-site crushing and on-site utilization" of construction waste, making it an ideal solution to the problems of high transportation costs and significant pollution associated with construction waste. Based on the different core crushing equipment, mobile crushing plants can be divided into three categories: jaw crusher mobile plants, impact crusher mobile plants, and hammer crusher mobile plants. Jaw crusher mobile plants are suitable for on-site coarse crushing, reducing the volume of large construction waste before transportation. Impact crusher mobile plants are suitable for on-site medium and fine crushing and shaping, directly producing qualified recycled aggregates. Hammer crusher mobile plants are suitable for small and medium-sized on-site processing projects, offering lower costs. Their core advantages include: firstly, high flexibility; tracked mobile plants can adapt to complex terrains such as mountains and mud, while wheeled mobile plants can be quickly moved by road to respond to sudden demolition projects; secondly, good environmental performance, equipped with enclosed enclosures, dust suppression spraying, and noise reduction equipment, with dust emission concentration ≤10mg/m³ and noise ≤85dB(A); and thirdly, integrated operation, combining feeding, crushing, screening, and sorting into one unit, eliminating the need for a fixed production line and allowing operation immediately upon startup.

In practical applications, mobile crushing plants are widely used in on-site crushing projects such as urban renewal and road expansion. In a redevelopment project in a provincial capital city, a tracked mobile impact crusher was used, processing 1,000 tons of demolition waste daily. The recycled aggregate produced was directly used for road subbase and foundation backfilling, reducing construction waste transportation by 80% and saving over one million yuan in transportation costs. Its main drawback is the high equipment purchase cost (approximately 1-1.5 million yuan for a small wheeled mobile station and 3-5 million yuan for a large tracked station), but in the long run, the cost can be recouped through savings in transportation expenses.

6. Key Selection Points for Various Types of Construction Waste Crushers

Selection should be based on a comprehensive assessment of project scale, material characteristics, product requirements, and environmental standards:

Large-scale projects (daily processing capacity > 1000 tons): Prioritize a fixed production line consisting of a jaw crusher + impact crusher + cone crusher to balance efficiency and product quality.

Small-to-medium-sized decentralized projects (daily processing capacity 100-500 tons): Choose a hammer crusher or a small mobile hammer crushing station to control investment and operating costs.

For projects with strong on-site processing needs: Prioritize mobile crushing stations, selecting jaw, impact, or hammer crushers as the core equipment based on material hardness.

High-hardness construction waste: Use a combination of a jaw crusher (coarse crushing) + cone crusher (medium and fine crushing) to improve wear resistance and crushing efficiency.

High-end recycled aggregate production: Use an impact crusher or cone crusher to ensure product particle shape and strength specifications.

The selection of construction waste crushers directly impacts processing efficiency, product quality, and return on investment. Different types of equipment have their own advantages and applicable scenarios: jaw crushers are essential for coarse crushing, impact crushers are the main equipment for medium and fine crushing and shaping, hammer crushers are an economical choice for small and medium-sized projects, cone crushers are fine-tuning equipment for high-hardness materials, and mobile crushing stations offer an integrated solution for on-site processing. With the continued advancement of policies promoting the resource utilization of construction waste, future crushers will develop towards intelligence (remote monitoring, automatic adjustment), environmental protection (low emissions, low noise), and large-scale production. The integration and modularization of various types of equipment will also continue to improve, providing stronger technical support for the high-quality development of the construction waste resource utilization industry.

Save Time! Get A Detailed Quotation Quickly.