In material crushing processes across industries such as mining, infrastructure construction, and building materials, cone crushers hold a core position due to their unique technological advantages. As a key piece of equipment for achieving fine crushing of materials, it breaks through the limitations of traditional crushing equipment, which suffers from low efficiency and poor particle shape, achieving high-efficiency crushing based on the principle of layered crushing. With the acceleration of industrialization and the upgrading of environmental protection requirements, the market has raised higher standards for the processing capacity, product quality, and energy consumption control of crushing equipment. This article will systematically review the core application scenarios of cone crushers, deeply analyze their technical characteristics and advantages, provide reference for industry selection and production optimization, and help related fields achieve efficient and low-carbon development.

1. Core Positioning and Application Areas of Cone Crusher The cone crusher is a high-efficiency crushing equipment designed based on the principle of layered crushing. With its advantages such as large crushing ratio, excellent product particle shape, and stable operation, it is widely used in various industries such as mining, building materials, metallurgy, chemicals, and highway and railway infrastructure, becoming a core piece of equipment for medium and fine crushing operations. The application scenarios of cone crushers can be specifically divided into the following categories: In the mining industry, cone crushers are key equipment for processing metallic ores (iron, copper, lead, zinc, etc.) and non-metallic ores (limestone, granite, basalt, etc.). For example, in iron ore beneficiation, it takes over the coarse crushing products from jaw crushers, crushing ore with a particle size of 50-100mm to 10-20mm, providing qualified raw materials for subsequent grinding and flotation processes. In granite quarries, by adjusting the crushing chamber shape, it can produce continuously graded crushed stone that meets building aggregate standards, satisfying different engineering needs. Furthermore, for high-hardness ores (Mohs hardness above 7), the wear-resistant liners and powerful crushing structure of cone crushers can effectively improve crushing efficiency and reduce energy consumption. Compared with traditional hammer crushers, its advantages in handling high-hardness materials are particularly obvious.

In the construction and building materials industry, cone crushers are mainly used in concrete aggregate production and cement raw material crushing. With the advancement of policies promoting the resource utilization of construction waste, cone crushers are also widely used in the processing of recycled aggregates. After crushing and screening waste concrete, bricks, and other materials, they produce recycled gravel and sand that meet national standards, achieving resource recycling. In large-scale commercial concrete mixing plants, cone crushers produce cubic aggregates with low needle-like and flaky content (typically below 10%), significantly improving the compressive strength and workability of concrete, making them the preferred equipment for high-quality aggregate production.

In the field of infrastructure engineering, projects such as highways, railways, bridges, and airport runways have extremely high requirements for the strength, gradation, and stability of aggregates. Cone crushers, with their precise output particle size control capabilities, have become core equipment for infrastructure aggregate production. For example, in high-speed rail construction, a large amount of uniformly sized, high-strength crushed stone is needed for roadbed filling and track subgrade. Cone crushers can adjust the output particle size in real time through a hydraulic adjustment system to ensure that the aggregate quality meets engineering design standards. In tunnel construction, their compact structural design allows them to adapt to confined working spaces, enabling continuous operation of mining and crushing simultaneously.

2. Core Technical Features of Cone Crusher

Layered Crushing Principle, Excellent Product Particle Shape:*The cone crusher uses the relative movement of the moving and fixed cones to subject the material to compression, bending, and shearing within the crushing chamber, forming a multi-layered crushing mode where material layers crush each other. This crushing method effectively reduces the generation of needle-like and flaky particles, resulting in cubic-shaped product particles with continuous and uniform gradation, meeting the stringent requirements for aggregate particle shape in high-grade construction and infrastructure projects. Compared to impact crushers, cone crushers have lower wear on wear-resistant parts and offer a more advantageous operating cost.

Large Crushing Ratio, High Processing Efficiency:*Cone crushers offer diverse crushing chamber designs (such as standard chamber, medium chamber, and short-head chamber), allowing for flexible selection based on material properties and discharge requirements. Their crushing ratio is typically between 4 and 8, and can reach over 10, enabling large materials to be crushed to the required particle size in a single pass, reducing crushing steps and improving overall production efficiency. Taking the PYB series spring cone crusher as an example, its processing capacity can reach 100-1500 t/h, suitable for the large-scale production needs of large mines and infrastructure projects.

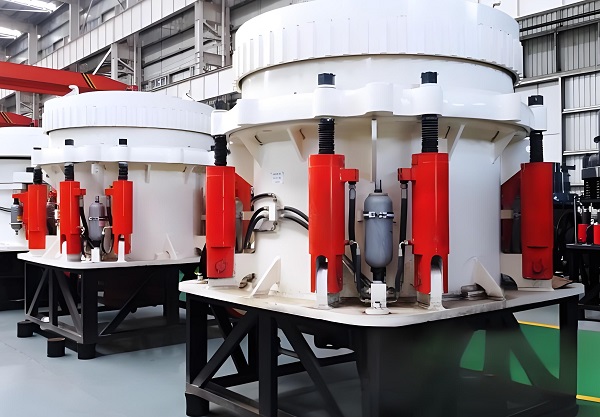

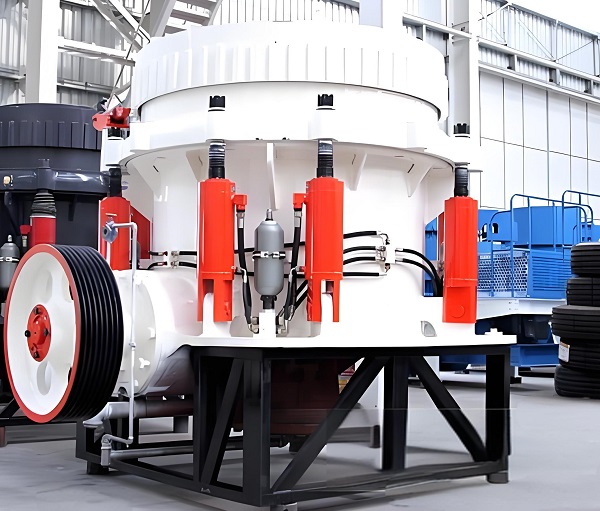

Compact structure and stable and reliable operation: Modern cone crushers adopt an integrated frame design, resulting in a compact structure, small footprint, and easy installation and transportation. Core components (moving cone, fixed cone, eccentric shaft) are forged from high-strength alloy steel and heat-treated to enhance wear resistance and impact resistance, extending service life. Simultaneously, the equipment is equipped with a complete lubrication and cooling system, ensuring stable operation of key components such as bearings under high-temperature and high-load conditions, reducing downtime due to malfunctions, and achieving an uptime rate of over 90%.

Hydraulic adjustment and protection system for convenient operation: Mainstream cone crushers are equipped with a hydraulic control system, which allows for rapid adjustment of the discharge opening size via hydraulic cylinders, enabling remote operation and automated control, improving production flexibility. Furthermore, the hydraulic protection system automatically increases the discharge port gap when the equipment encounters uncrushable objects (such as iron blocks), allowing the foreign objects to be discharged and preventing overload damage. It automatically resets after the foreign objects are discharged, ensuring safe operation. Some high-end models also integrate an intelligent monitoring system that can monitor equipment operating parameters (such as temperature, vibration, and load) in real time, enabling fault warnings and remote diagnostics.

Low energy consumption and outstanding environmental performance: Compared to traditional crushing equipment, cone crushers have lower unit energy consumption, consuming only 1-3 kWh of electricity per ton of material crushed, complying with energy-saving and emission-reduction industrial policies. Simultaneously, the equipment adopts a fully sealed structure design, coupled with a high-efficiency dust removal device, effectively reducing dust leakage and noise pollution. Some models also optimize the airflow channel of the crushing chamber, reducing dust generation and meeting environmental emission standards, making them suitable for production projects in urban peripheries and ecologically sensitive areas with high environmental requirements.

3. Development Trends of Cone Crusher

With the technological upgrading of the mining machinery industry and the continuous improvement of environmental protection requirements, cone crushers are developing towards intelligence, large-scale production, and green manufacturing. In the future, equipment will further integrate IoT technology to achieve intelligent control of the entire production process; large-scale models (with a processing capacity of 2000t/h or more) will become the mainstream choice for large-scale mining projects; simultaneously, the application of new wear-resistant materials and the optimization of the crushing chamber structure will further improve the service life and crushing efficiency of the equipment, contributing to the high-quality development of the industry.

Cone crushers, with layered crushing technology at their core, demonstrate irreplaceable application value in mining, infrastructure, building materials, and other industries. Their superior particle shape, large crushing ratio, stable operation, convenient operation, and environmental friendliness and energy efficiency perfectly meet the diverse needs of modern industry for crushing equipment. From high-hardness ore processing to recycled aggregate production, from large-scale infrastructure projects to refined production scenarios, cone crushers can provide efficient solutions. In the future, with the continuous iteration of intelligent, large-scale, and green technologies, cone crushers will further improve their adaptability and cost-effectiveness, providing stronger equipment support for cost reduction, efficiency improvement, and green transformation in various industries, promoting the high-quality development of the crushing industry.

Save Time! Get A Detailed Quotation Quickly.