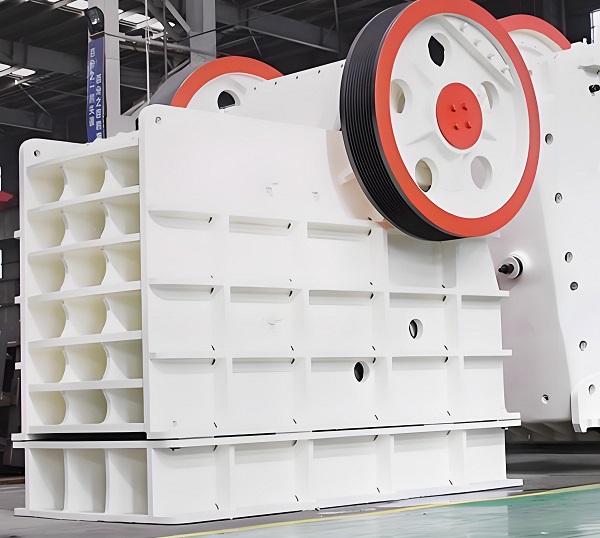

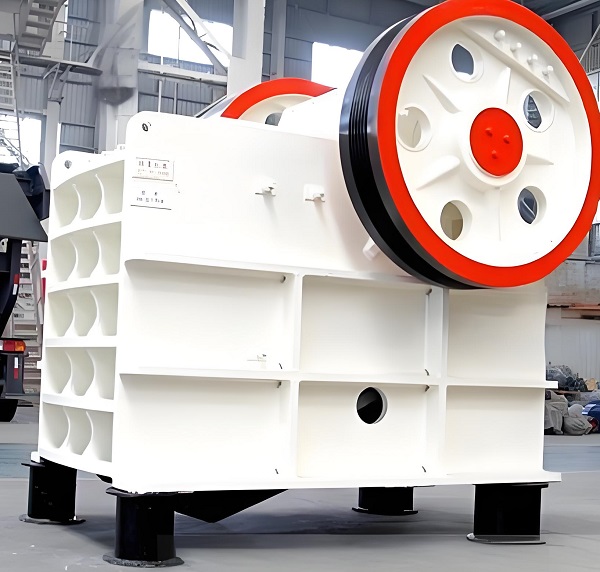

In industrial coarse crushing scenarios such as mining, construction aggregate production, and construction waste disposal, the jaw crusher (abbreviated as "jaw crusher") is the core equipment for achieving initial material crushing. As an upgraded iteration of the traditional jaw crusher, the European-version jaw crusher combines advanced European crushing technology with localized production requirements. It has been comprehensively optimized in terms of structural design, crushing efficiency, and operational stability. It is particularly suitable for coarse crushing of high-hardness, highly abrasive materials (such as granite, basalt, and iron ore). Compared to traditional jaw crushers, the European-version jaw crusher not only continues the advantages of "simple structure and easy operation," but also achieves breakthroughs in energy efficiency, product quality, and maintenance costs, making it one of the mainstream models in the current industrial coarse crushing field. This article will systematically analyze the characteristics and advantages of the European-version jaw crusher from the aspects of core structure, operating performance, and application adaptability, providing a reference for enterprises to select equipment.

Core Structure Optimization: From "Basic Crushing" to "High Efficiency and Stability"

The advantages of the European-style jaw crusher stem from a targeted upgrade of the traditional jaw crusher structure. By optimizing key components such as the crushing chamber, drive system, and support structure, the crushing capacity and operational reliability of the equipment have been significantly improved. Its specific features can be summarized as follows:

1. "Deep V-shaped crushing chamber" design improves crushing efficiency and feed capacity

Traditional jaw crushers often have a shallow, linear crushing chamber, which can lead to problems such as limited feed size, easy material bridging and blockage, and inadequate crushing due to a short crushing stroke. The European-style jaw crusher utilizes a deep V-shaped crushing chamber design, with key optimizations in two key areas: First, the chamber depth has been increased by 30%-50%, accommodating larger material sizes (for example, the maximum feed size for large European-style jaw crushers can reach over 1200mm), eliminating the need for pre-crushing of bulky materials and reducing production steps. Second, the chamber wall features a tapered curve design, with the inclination angle gradually adjusting from the feed inlet to the discharge outlet. Combined with the large swing angle of the movable jaw (20%-30% greater than traditional equipment), this extends the material's residence time in the crushing chamber, allowing it to undergo multiple compression and shear crushing cycles, thereby avoiding the problem of over-coarse finished products caused by "one-time impact crushing."

2. The reinforced movable jaw and frame enhance impact and wear resistance.

In industrial coarse crushing operations, impact and wear on equipment are the main causes of equipment failure. The European version of the jaw crusher has been comprehensively strengthened in the strength design of key load-bearing components: First, the movable jaw adopts an "integral cast steel + rib-type reinforcement" structure, and the material is high-strength alloy steel (such as ZG35CrMo). After tempering heat treatment, the tensile strength can reach more than 800MPa, which is more than 50% higher than the impact resistance of the traditional cast iron movable jaw. It can withstand repeated impacts of high-hardness materials without easily deforming; second, the frame adopts a "box-type welded structure", and the stress distribution is optimized through finite element analysis to reduce welding deformation. At the same time, the inner wall of the frame is lined with wear-resistant steel plates (such as NM450) to prevent direct wear of the frame by materials and extend the service life of the frame. In addition, the toggle plate and toggle pad of the European-style jaw crusher are made of a high-toughness alloy (such as ZGMn13) and designed with an arc-shaped structure. This not only effectively transmits crushing force but also breaks first when encountering unbreakable foreign objects (such as iron blocks), providing overload protection and preventing damage to core components such as the movable jaw and main shaft. Compared to the rigid toggle plates of traditional jaw crushers, the arc-shaped toggle plate provides more responsive protection and lowers replacement costs (only 60% of traditional toggle plates).

3. Optimizing the transmission system to reduce energy consumption and noise

The transmission system of traditional jaw crushers often uses a simple combination of "motor + V-belt + eccentric shaft," which can lead to low transmission efficiency, high noise levels, and V-belt slippage. The European-version jaw crusher features two upgrades to its transmission system: First, it adopts a "large-diameter eccentric shaft + heavy-duty bearing" design. The eccentric shaft diameter is 15%-20% larger than traditional equipment. Combined with spherical roller bearings (such as 22330CC/W33), it can withstand greater radial and axial loads, increasing transmission efficiency to over 95% (compared to approximately 85% for traditional equipment). Second, it is equipped with an "automatic V-belt tensioner" that uses a spring to automatically compensate for V-belt slack, preventing power loss caused by belt slippage and reducing the need for manual belt tension adjustment.

For noise control, the European-version jaw crusher uses a rubber seal between the movable jaw and the frame for vibration reduction, a shock-absorbing foot pad is installed on the motor base, and the wear-resistant lining of the crushing chamber is made of damping material. These multiple measures keep operating noise levels below 85 decibels (compared to 95-105 decibels for traditional jaw crushers), meeting national noise emission standards for industrial plants and improving the working environment.

Operational Performance Advantages: From "Meeting Basic Needs" to "Improving Production Efficiency"

Based on its optimized structure, the European-style jaw crusher demonstrates its core advantages of "high efficiency, energy saving, high quality, and stability" in actual operation. These advantages directly translate into improved production efficiency and reduced costs for enterprises. They can be summarized in the following four key points:

1. High Crushing Efficiency, Suitable for Coarse Crushing of High-Hardness Materials

The European-style jaw crusher's "deep crushing chamber + large-swing jaw design" significantly outperforms traditional equipment in handling high-hardness, large-particle materials. The deep crushing chamber design increases the single feed volume and reduces material accumulation at the feed port. Furthermore, the large-swing jaw extends the crushing stroke, increasing the number of material breaks within the crushing chamber and achieving more complete crushing. Data shows that, with the same specifications, the European-style jaw crusher has an hourly throughput 20%-40% higher than traditional jaw crushers. For example, a traditional PE-900×1200 jaw crusher can process approximately 100-150 tons of granite per hour, while a European-style jaw crusher of the same specifications can reach 150-210 tons.

Furthermore, the crushing force of the European-style jaw crusher can be flexibly adapted to different material hardness by adjusting the eccentric shaft speed (typically 200-300 rpm). When processing limestone and sandstone with a Mohs hardness of 6-8, the speed can be reduced to increase the throughput; when processing granite and basalt with a Mohs hardness of 8-10, the speed can be increased to enhance the crushing force, ensuring thorough material crushing and avoiding the problem of "substandard primary crushing leading to increased load in subsequent processes."

2. Uniform finished product particle size reduces subsequent crushing load

In industrial production, materials after coarse crushing need to be further processed in secondary and tertiary crushing equipment (such as cone crushers and impact crushers). If the coarse crushed product particle size is uneven, with a high proportion of coarse particles, the crushing load on the subsequent equipment will increase energy consumption and accelerate wear of wearing parts. The European-style jaw crusher effectively controls the finished product particle size through a "gradually converging crushing chamber + precise discharge opening adjustment." First, the gradually converging chamber gradually compresses and refines the material during the crushing process, preventing "localized over-coarseness." Second, the discharge opening utilizes a "wedge-type adjustment device" with a wider adjustment range (typically 10-300mm) and an adjustment accuracy of up to ±1mm, enabling precise control of the coarse crushed product particle size based on the needs of subsequent processes.

3. Outstanding Energy Saving and Low Long-Term Operating Costs

The energy-saving advantages of the European-style jaw crusher are primarily reflected in "improved transmission efficiency" and "reduced crushing energy consumption." First, the optimized transmission system reduces power loss. At the same processing capacity, the motor power of the European-style jaw crusher is 10%-20% lower than that of traditional equipment. For example, to process 200 tons/hour of granite, a traditional jaw crusher requires a 160kW motor, while the European-style jaw crusher only requires a 132kW motor. This saves 28 kWh of electricity per hour, and over 7,000 hours of operation, this translates to approximately 196,000 yuan in electricity bills (at 1 yuan/kWh) per year. Second, the enhanced "laminated crushing effect" reduces direct friction between the material and the liner within the crushing chamber, reducing liner wear by 30%-50%. This extends the liner replacement cycle from 1-2 months with traditional equipment to 3-4 months, reducing liner replacement costs by 2-5% annually. 10,000 yuan.

In addition, the European-version jaw crusher's "automatic V-belt tensioner" eliminates the extra energy consumption caused by belt slippage, further reducing operating costs. Over long-term use, its lifecycle energy consumption cost is 25%-35% lower than that of a traditional jaw crusher.

4. High operational stability, reduced downtime losses

The continuous operation of industrial production lines requires extremely high equipment stability. The European-version jaw crusher significantly improves operational stability through structural reinforcement and optimized protective devices. First, the reinforced movable jaw and frame can withstand the impact of high-hardness materials, reducing component deformation and failure. Second, the overload protection function of the "arc-shaped toggle plate" quickly breaks when encountering foreign objects, preventing damage to core components. The toggle plate is easy to replace, taking only 1-2 hours (compared to 3-4 hours for traditional jaw crushers). Third, the combined sealing design of "labyrinth seal + dust ring" effectively prevents dust from entering the bearings and transmission parts, preventing lubricant contamination, and extending the bearing service life to over 8,000 hours (compared to approximately 5,000 hours for traditional equipment).

Application Adaptability Advantages: From "Single Scenario" to "Multi-Field Compatibility"

The European-version jaw crusher's structural and performance advantages make it highly adaptable to various applications, meeting the primary crushing needs of various industries and materials. It excels particularly in the following scenarios:

1. Mining: A "workhorse" for primary crushing of high-hardness ores

In the mining of metal ores (iron ore, copper ore) and non-metallic ores (granite, basalt), the ore has a large particle size (typically 500-1500mm) and high hardness, placing extremely high demands on the primary crushing equipment for impact and wear resistance. The European-version jaw crusher's deep crushing chamber can directly handle large-size ore, and its reinforced structure can withstand repeated impacts, making it a "workhorse" in mining primary crushing lines. For example, a large iron mine uses a PE-1200×1500 European-style jaw crusher to coarsely crush iron ore with a particle size of 1200mm to less than 250mm, with an hourly processing capacity of 300 tons. Combined with a subsequent hydraulic cone crusher, this achieves a continuous "coarse-secondary-final" crushing process, processing 2 million tons of iron ore annually.

2. Construction Aggregate Production: A "Guaranteed Equipment" for High-Quality Aggregate Coarse Crushing

Construction aggregates (crushed stone, pebbles) require stringent particle shape and size uniformity. The European-style jaw crusher's tapered crushing chamber and precise discharge adjustment ensure uniform coarse crushed product size, providing high-quality raw material for subsequent secondary and fine crushing equipment. For example, in highway aggregate production lines, European-style jaw crushers crush granite to sizes below 150mm, resulting in a flake-like content of less than 8% in the finished product. Subsequent reshaping in impact crushers reduces the flake-like content to less than 5%, meeting the material requirements for high-standard projects such as high-speed railways and bridges.

3. Construction Waste Processing: An "Efficient Equipment" for Volume Reduction of Large Waste Blocks

With the advancement of construction waste resource utilization, the demand for coarse crushing of large concrete blocks and waste bricks is increasing. These materials have complex composition, uneven hardness, and may contain foreign matter such as rebar. The European-style jaw crusher's deep crushing chamber can handle construction waste blocks with a diameter of 800mm or larger. The overload protection function of the curved toggle plate prevents damage to the equipment from foreign matter such as rebar. Furthermore, the crushed construction waste blocks have a uniform particle size, making them easier to sort and recycle. For example, a construction waste treatment plant uses a European-style jaw crusher to crush waste concrete blocks to less than 300mm, with an hourly processing capacity of 150 tons. The crushed material, after sorting, can be made into recycled aggregate for road base construction, achieving a resource recovery rate of over 90%.

By optimizing the structure and upgrading its technology over traditional jaw crushers, the European-style jaw crusher demonstrates significant advantages in terms of efficient crushing, high-quality finished products, energy conservation and consumption reduction, and stable operation. It not only addresses the pain points of traditional equipment, such as low efficiency, high energy consumption, and frequent failures, but also adapts to the coarse crushing needs of various industries, including mining, construction, and construction waste treatment, making it an "upgrade option" in the industrial coarse crushing sector.

For businesses, choosing a European-style jaw crusher is more than just purchasing a piece of equipment; it equips their production line with an "efficient and stable coarse crushing core"—creating long-term benefits by improving crushing efficiency, reducing operating costs, and minimizing downtime losses. When selecting a model, it is recommended that companies choose a European-style jaw crusher with suitable specifications based on their own material characteristics (hardness, particle size), production capacity requirements and subsequent process requirements, and give priority to manufacturers with "customized design + comprehensive after-sales service" to ensure that the equipment can fully exert its performance and help improve production efficiency.

Save Time! Get A Detailed Quotation Quickly.