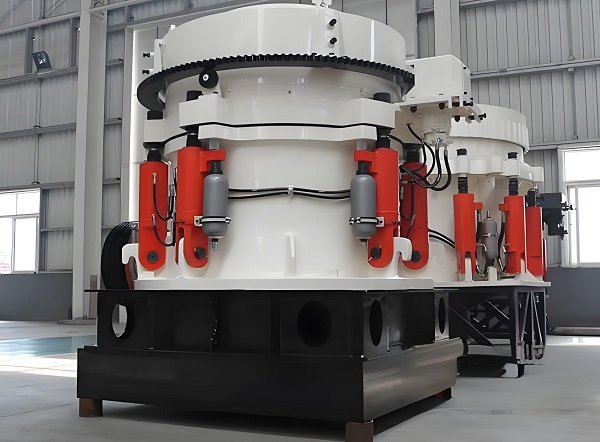

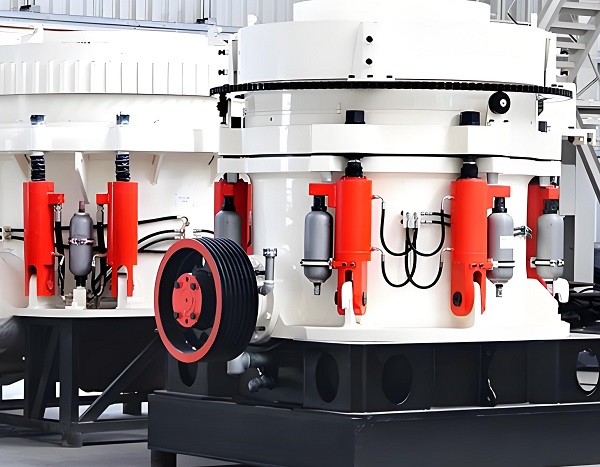

Hydraulic cone crushers are core equipment for fine crushing of high-hardness materials in industries like mining and construction. Their selection and procurement directly impact production line efficiency, crushing costs, and finished product quality. However, the market is rife with a wide variety of equipment models and varying manufacturer qualifications, leading many companies to fall into the trap of focusing solely on price and blindly following trends when purchasing. Starting with clarifying your needs, this article will gradually break down key steps, including equipment performance review, manufacturer selection, price comparison, and after-sales service evaluation. It also covers key contract risk mitigation strategies. This article provides a practical selection process for companies of varying sizes and material requirements, helping readers avoid purchasing pitfalls and select a hydraulic cone crusher that's suitable for their production and offers the best value.

Purchasing a hydraulic cone crusher requires comprehensive consideration of multiple factors. The following is a detailed purchasing guide:

Clarify Your Needs

Determine the material to be crushed: Different hydraulic cone crushers have different suitability for different materials. Be clear about the type of material you need to crush, such as river pebbles, granite, limestone, and other characteristics, including hardness, moisture content, and particle size. For example, granite has a high hardness, so equipment with strong crushing capacity and good wear resistance is required.

Planning Production Capacity: Determine the required hydraulic cone crusher capacity based on your production scale and output requirements. Refer to the manufacturer's technical specifications to select a model that can meet your daily production needs. For example, large-scale mining companies that process large quantities of ore daily will need equipment with a higher production capacity.

Clearing Crushing Standards: Hydraulic cone crushers come in various types, such as fully hydraulic cone crushers, single-cylinder cone crushers, and multi-cylinder cone crushers. Each type has different crushing standards and production ranges. It's important to clearly define your requirements for crushed product particle size and shape to select the appropriate equipment.

2. Examining Equipment Performance

Understanding the Crushing Principle: Hydraulic cone crushers primarily use a hydraulic system to push the crushing wall to squeeze and crush the material. The crushing principles used by different manufacturers may vary slightly, so understanding their working principles can help you better evaluate the equipment's performance and suitability.

Focus on the quality of key components: The quality of vulnerable parts, such as the crushing wall and mortar wall, directly impacts the equipment's service life and crushing performance. Choose components made of high-quality, wear-resistant materials, and pay attention to the manufacturer's manufacturing processes and quality control systems.

Evaluate hydraulic system performance: The hydraulic system is the core component of the hydraulic cone crusher, ensuring stable and reliable performance. You can understand parameters such as the hydraulic system's brand, operating pressure, and flow rate, as well as whether it has overload protection and automatic adjustment features.

3. Select a reliable manufacturer

Research the manufacturer's capabilities: You can use the internet, industry reports, and recommendations from friends to understand the manufacturer's scale, production capacity, and technological R&D capabilities. Manufacturers with many years of production experience, large scale, and advanced technology are generally more reliable for their product quality and after-sales service.

Review the manufacturer's reputation: Check the manufacturer's industry reputation and user reviews. You can review the manufacturer's official website, industry forums, and customer case studies to learn about other users' experiences with the manufacturer's equipment, quality feedback, and after-sales service.

Visit the manufacturer: If conditions permit, visit the manufacturer in person. This allows you to gain a direct understanding of the manufacturer's production environment, production processes, and quality control procedures. You can also observe the equipment in action and have face-to-face communication and interaction with the manufacturer's technical and sales staff.

4. Compare Product Prices

Get Multiple Quotes: Inquire about hydraulic cone crusher prices from multiple manufacturers through online and offline channels. You can obtain quotes through the manufacturer's official website, by phone, or by email. Also, be sure to check whether the quote includes shipping, installation, taxes, and other fees.

Analyze the Reasons for Price Differences: Prices can vary significantly between manufacturers, so analyze the reasons for these differences. These may be due to factors such as the equipment model, configuration, quality, and brand, as well as the manufacturer's marketing strategy and production costs. Don't solely base your selection on price; consider the equipment's performance and quality comprehensively.

Seek Discounts: When communicating with the manufacturer, inquire about any discounts offered, such as group buy discounts, holiday promotions, or discounts for repeat customers. You can also negotiate terms such as price, payment method, and delivery time to secure more favorable purchase terms.

5. Focus on After-Sales Service

Learn about After-Sales Service: Ask about the manufacturer's after-sales service offerings, including equipment installation and commissioning, training, maintenance, and spare parts supply. Ensure the manufacturer provides timely and effective after-sales service to ensure the equipment's normal operation. Investigate the after-sales service team: Understand the size, technical level, and response time of the manufacturer's after-sales service team. A professional and efficient after-sales service team can quickly arrive on-site when equipment malfunctions occur, resolve issues, and minimize downtime.

Clarify the warranty period and scope: Clarify the manufacturer's warranty period and scope, and understand the repair and replacement policies during the warranty period. Also, pay attention to the specific details of the warranty terms to avoid disputes.

6. Sign the Purchase Contract

Clarify the contract terms: Before signing the purchase contract, carefully read the contract terms to ensure they are clear and specific, including the equipment model, specifications, quantity, price, delivery date, quality standards, and after-sales service terms.

Agree on liability for breach of contract: Clarify the liability for breach of contract and the method of compensation for each party to protect your legal rights. For example, if the manufacturer fails to deliver on time, it will bear the corresponding liability for breach of contract. If the equipment quality does not meet your requirements, the user has the right to request a replacement or return.

Retain relevant evidence: During the purchase process, retain all relevant evidence, such as quotations, contracts, invoices, emails, and chat logs, to prepare for possible disputes in the future.

Choosing a hydraulic cone crusher isn't a matter of simply comparing single parameters; it's a comprehensive decision that balances needs, reliable performance, manageable costs, and guaranteed service. From clarifying material characteristics and production capacity requirements to thoroughly examining the quality of core components like the hydraulic system and consumable parts; from selecting a competent and reputable manufacturer to rationally comparing prices and securing comprehensive after-sales support, every step requires rigorous consideration. After all, a suitable hydraulic cone crusher not only boosts current production but also helps companies maintain long-term stable operations by reducing maintenance costs and downtime losses.

Before purchasing, it's recommended that companies create a "requirements list" and "key inspection points" based on the process outlined in this article. If necessary, conduct a joint evaluation with multiple departments, including technical, production, and finance. If conditions permit, prioritize manufacturers that offer a "customized solution + on-site trial" service. Remember, a sound purchasing decision isn't about "buying the cheapest equipment," but rather "buying the equipment that best suits your needs." Only in this way can a hydraulic cone crusher maximize its value in your production line and generate sustainable profits for your company.

Save Time! Get A Detailed Quotation Quickly.