In the modern industrial crushing field, with the continuous improvement of requirements for material crushing precision, processing efficiency, and automation, multi-roll crushers, as an upgraded version of double-roll crushers, have demonstrated strong application potential in fine crushing, ultrafine crushing, and high-precision grading crushing scenarios due to their unique multi-roll collaborative operation structure. Multi-roll crushers typically consist of three or more parallel crushing rolls, achieving integrated processing of materials from coarse to fine crushing through continuous squeezing, shearing, and grinding actions between the rolls. Compared with traditional double-roll crushers, they have made significant breakthroughs in structural design, performance, and applicable scenarios. A thorough exploration of their characteristics and advantages is of great significance for promoting crushing process optimization and improving production efficiency.

I. Core Characteristics of Multi-roll Crusher The characteristics of multi-roll crushers stem from their core multi-roll collaborative structure. This structural design makes them significantly different from traditional crushing equipment in terms of crushing mechanism, particle size control, and operating characteristics, which can be summarized in the following six aspects.

1. Multi-roller staged crushing with a large and uniform crushing ratio. The most significant feature of a multi-roller crusher is its staged crushing mode. The rollers are typically arranged in a "coarse crushing-medium crushing-fine crushing" sequence, with the gaps between rollers decreasing progressively. After entering through the feed inlet, the material is initially crushed by the preceding rollers, reducing its particle size before entering the subsequent rollers for further crushing, ultimately achieving the target particle size. This continuous crushing method significantly increases the material crushing ratio (the ratio of feed particle size to output particle size), typically reaching 10-20, far exceeding the 3-5 of a two-roller crusher. Simultaneously, because each stage of crushing is completed within precisely controlled gaps, the force exerted on the material between the rollers is uniform, avoiding the problem of "large particles not crushed and small particles over-crushed" found in traditional single-stage crushing. The output particle size distribution is concentrated, with a non-uniformity coefficient typically less than 1.5, and the fine powder content can be controlled below 5%. This makes it particularly suitable for production scenarios with stringent particle size requirements, such as the crushing of lithium battery positive and negative electrode materials and the grinding of pharmaceutical intermediates.

2. Diverse Roller Surface Designs, Wide Adaptability

To adapt to the crushing needs of different materials, multi-roller crushers feature diverse roller surface designs, which can be flexibly combined according to the crushing functions at each stage. The coarse crushing stage typically uses toothed or grooved rollers, utilizing the shearing force of sharp teeth to quickly crush lumpy materials and prevent slippage. The medium crushing stage often uses corrugated rollers to enhance material gripping ability while reducing dust during the crushing process. The fine crushing stage uses smooth rollers or ultra-fine grinding rollers, ensuring uniform and fine output particle size through high-precision surface compression and grinding. For example, in coal desulfurization processes, toothed rollers are used in the coarse crushing stage to crush large pieces of raw coal, corrugated rollers are used in the medium crushing stage to separate coal from gangue, and smooth rollers are used in the fine crushing stage to control the particle size of clean coal, achieving integrated "crushing-sorting." In non-metallic mineral processing, by combining different roller surfaces, various materials ranging from brittle to sticky, such as quartz sand and kaolin, can be effectively processed.

Furthermore, some advanced models adopt a quick-replacement roller sleeve design, secured by bolts or hydraulic devices, reducing replacement time to 1-2 hours. Compared to traditional integral roller bodies, this saves over 80% of maintenance time, further enhancing the equipment's adaptability to producing a variety of materials.

3. Intelligent Linkage Control, High Degree of Automation The multi-roll crusher integrates modern sensing technology and an intelligent control system, achieving precise linkage and automated adjustment of the roller group's operation. The equipment is equipped with multiple pressure sensors, speed sensors, and online particle size detection devices to monitor the material load between rollers, roller speed, and discharge particle size in real time. When the feed rate fluctuates, the control system automatically adjusts the speed of the preceding rollers to prevent material accumulation; when the discharge particle size deviates from the set value, the hydraulic actuator precisely adjusts the gap between rollers with an adjustment accuracy of up to 0.01mm; some high-end models also support integration with the MES production management system, enabling remote monitoring of production parameters, data traceability, and process optimization. For example, in lithium battery material production lines, multi-roll crushers can automatically match the optimal roller speed and gap parameters according to the particle size requirements of the cathode material, and upload production data to the cloud to achieve fully automated control of the entire process, significantly reducing the cost of manual intervention.

This highly automated control method not only improves production stability but also enables the equipment to quickly respond to process adjustment needs, adapting to flexible production modes of multiple batches and small quantities, which aligns with the development trend of modern manufacturing.

4. Low-impact crushing mechanism, low material loss

Unlike jaw crushers and impact crushers, which rely on impact to crush materials, multi-roll crushers use static compression and gentle shearing as the main crushing mechanism. The roller speed is relatively low (usually 10-50 r/min), and the material is not subjected to severe impact and collision during the crushing process. This crushing method is particularly important for materials with specific physical property requirements: for brittle materials (such as ceramics and glass), it effectively reduces edge breakage and fine powder generation during crushing; for functional materials (such as lithium battery electrodes and rare earth materials), it maximizes the preservation of the material's original structure and properties, preventing component oxidation or structural damage; for valuable materials (such as precious metal ores and gemstone raw materials), it reduces material loss and increases finished product recovery rate.

Data shows that in precious metal ore crushing, the material recovery rate of multi-roll crushers is 3%-5% higher than that of impact crushers; in lithium battery electrode recovery, the structural retention rate of cathode materials can reach over 90%, significantly improving the utilization value of the material.

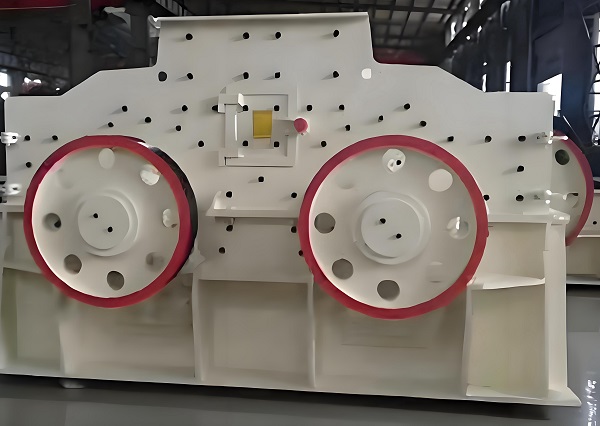

5. Compact and integrated structure, small footprint. The multi-roll crusher integrates multiple processes of "coarse crushing, medium crushing, and fine crushing" into the same main body of the equipment. By optimizing the roller group layout and transmission structure, it achieves a "one machine, multiple functions" crushing effect. Compared to traditional multi-stage crushing production lines consisting of a jaw crusher, cone crusher, and impact crusher, multi-roll crushers can reduce the floor space by over 60% and the equipment weight by approximately 40%. For example, a limestone fine crushing production line with a capacity of 50 t/h would require approximately 100 square meters of workshop space using traditional equipment, while a four-roll crusher can complete the same crushing operation in just 30 square meters.

This compact design not only reduces workshop construction costs and equipment installation difficulty but also reduces material conveying links between different pieces of equipment, shortening the production process and reducing material loss and energy consumption during conveying. It is particularly suitable for small and medium-sized enterprises with limited workshop space or for upgrading and retrofitting older production lines.

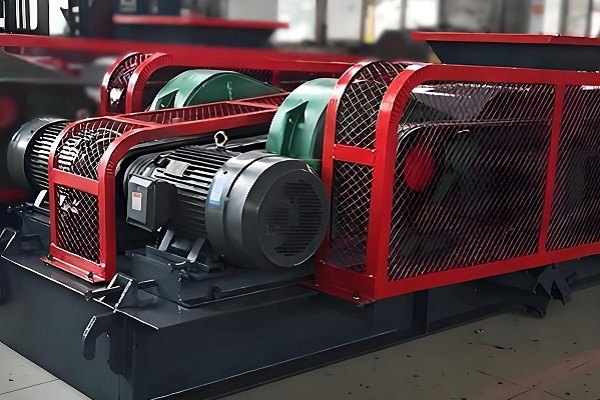

6. Stable and reliable operation, controllable maintenance costs. The transmission system of the multi-roll crusher adopts a modular design of "motor-reducer-universal coupling." Each roller is driven independently and controlled by an intelligent system, avoiding the problem of the entire machine shutting down due to a single transmission failure, as is common in traditional equipment. Meanwhile, the main wear parts of the equipment are the roller surfaces, which are made of wear-resistant materials such as high-chromium alloy and tungsten carbide. After special heat treatment, their hardness can reach HRC60 or higher, extending their service life by 2-3 times compared to the rollers of traditional double-roll crushers. For roller surface wear, refurbishment can be achieved through welding repair technology, with repair costs only 1/3 to 1/2 of replacing a new roller.

Furthermore, the equipment is equipped with a comprehensive online monitoring system that can provide real-time warnings of roller surface wear, abnormal bearing temperature, and other faults, enabling "preventive maintenance." This keeps equipment downtime to less than 2 hours per month, effectively improving equipment operating rates and reducing maintenance costs and the risk of production interruptions.

II. Application Advantages of Multi-Roll Crusher

Based on the above characteristics, multi-roll crushers exhibit significant competitive advantages in industrial applications. They not only improve the technical level of crushing processes but also bring considerable economic and environmental benefits to enterprises. Their advantages are mainly reflected in the following five aspects:

1. Improved Quality and Efficiency, Enhancing Product Market Competitiveness

The multi-roll crusher's grading crushing mode and precise particle size control capability can significantly improve the quality of crushed products. On the one hand, the uniform particle size and low fine powder content of the output reduce the load on subsequent screening processes and lower the defect rate. On the other hand, the low-impact crushing mechanism preserves the excellent properties of the material, making it easier for the product to meet process requirements in subsequent processing. For example, in the production of architectural ceramics, using a multi-roll crusher to crush kaolin can control the particle size to below 200 mesh, with uniform particle distribution. The resulting ceramic blanks have higher density and better sintering performance, increasing the product qualification rate from 85% with traditional equipment to 98%. In the production of lithium battery materials, the regular morphology of the crushed cathode material particles helps improve the battery's charge and discharge efficiency and cycle life, making the product more competitive in the market.

2. Energy Saving and Reduced Consumption, Lowering Production and Operating Costs

The energy-saving advantages of multi-roll crushers are mainly reflected in two aspects: First, high crushing efficiency. The coordinated operation of multiple rollers allows materials to complete multiple crushing processes in a single equipment run, avoiding energy losses from material conveying and repeated crushing in traditional multi-stage crushing. Unit product energy consumption is reduced by 30%-50% compared to traditional crushing production lines. Second, low operating energy consumption. The rollers adopt a low-speed, heavy-load design, and the motor power is more rationally matched. Compared to impact crushers with the same processing capacity, motor power can be reduced by 20%-30%. Taking a limestone crushing production line with a processing capacity of 100t/h as an example, replacing the traditional "jaw crusher + cone crusher" combination with a six-roll crusher can save approximately 800,000 yuan in electricity costs annually.

At the same time, low equipment maintenance costs and minimal material loss further reduce production and operating costs. Statistics show that enterprises using multi-roll crushers can reduce the overall cost of the crushing process by 25%-40%, significantly improving their profitability.

3. Expanding Application Scenarios to Adapt to Specialized Crushing Needs

Compared to traditional crushing equipment, multi-roll crushers possess irreplaceable advantages in the field of specialized material crushing. Their applications have expanded from traditional mining and building materials industries to multiple high-end sectors such as new energy, pharmaceuticals, food, and chemicals. In the new energy sector, they are used for lithium battery electrode recycling and photovoltaic silicon material crushing, achieving efficient material dissociation while preserving performance. In the pharmaceutical sector, they are used for crushing traditional Chinese medicine slices and pharmaceutical excipients, controlling particle size to 100-300 mesh while avoiding metal contamination. In the food sector, they are used for crushing and grading grains and nuts, achieving precise particle size control and improving food processing quality. In the chemical sector, they are used for crushing plastic granules and rubber waste, reducing high-temperature degradation and increasing recycling value.

This wide range of application adaptability makes multi-roll crushers a key piece of equipment driving the upgrading of crushing processes across various industries, especially in high-end manufacturing, where market demand is growing at a rate of 15%-20% annually.

4. Green and Environmentally Friendly, Meeting the Requirements of Modern Industrial Development

Against increasingly stringent environmental protection requirements, the green and environmentally friendly advantages of multi-roll crushers are becoming increasingly prominent. Firstly, dust pollution is low. The equipment adopts a fully enclosed casing design, with dustproof sealing devices at the feed and discharge ports. Internal guide plates and dust collection chambers control dust emissions to below 10mg/m³, far below the national emission standard (30mg/m³). Secondly, noise pollution is low. The rollers operate at low speed and use flexible connection devices, controlling the equipment's operating noise to below 75 decibels, a reduction of 20-30 decibels compared to impact crushers, eliminating the need for additional noise reduction equipment. Thirdly, energy consumption and carbon emissions are low. The carbon emissions per unit product are reduced by more than 30% compared to traditional crushing equipment, meeting the "dual-carbon" development goals.

For example, in the upgrading and transformation of a building materials company, after replacing the traditional impact crusher with a multi-roll crusher, the dust concentration in the workshop decreased from 50mg/m³ to 8mg/m³, and the noise level decreased from 95 decibels to 72 decibels, reducing carbon emissions by approximately 1200 tons annually. This not only improved the working environment but also earned environmental subsidies from the local government.

5. Intelligent Linkage, Facilitating Digital Production Transformation The intelligent control system of the multi-roll crusher can be deeply integrated with the company's digital production system, achieving full-process digital management of the crushing process. Through the Industrial Internet, equipment operating data (such as throughput, energy consumption, particle size parameters, etc.) is uploaded to the cloud platform in real time. Managers can remotely monitor equipment operating status, analyze production data, and optimize process parameters. For example, on the intelligent production line of a large mine, the multi-roll crusher is linked with the automated feeder, screening machine, and conveyor to form an "unattended" crushing unit. Through big data analysis and optimization of roller speed and gap parameters, the equipment throughput increased by 15% and energy consumption decreased by 20%. This intelligent advantage not only improves production management efficiency but also provides strong support for enterprises to achieve digital transformation, shifting the crushing process from traditional "experience-based operation" to "data-driven" operation, and promoting the intelligent upgrading of the entire manufacturing industry.

Multi-roll crushers, with their core features such as multi-roller grading crushing, intelligent linkage control, low consumption and environmental protection, as well as significant advantages such as improving quality and efficiency, expanding applications, and assisting digital transformation, are gradually becoming core equipment in the modern crushing field. Their development history is a microcosm of the transformation of crushing equipment from "single function" to "multi-functional integration," from "mechanical operation" to "intelligent control," and from "high consumption and pollution" to "green and efficient." With the continuous advancement of materials science and intelligent control technology, multi-roll crushers will develop towards higher precision, greater capacity, and wider adaptability, such as developing nanoscale crushing roller surfaces, achieving AI adaptive control, and expanding into areas such as high-temperature material crushing. For enterprises, fully understanding the characteristics and advantages of multi-roll crushers and rationally selecting models based on their own production needs will effectively optimize crushing processes, improve production efficiency, and gain a favorable position in the fierce market competition. Meanwhile, the promotion and application of multi-roll crushers will also make an important contribution to promoting the green and intelligent development of the crushing industry and achieving the goal of "carbon peaking and carbon neutrality".

Save Time! Get A Detailed Quotation Quickly.