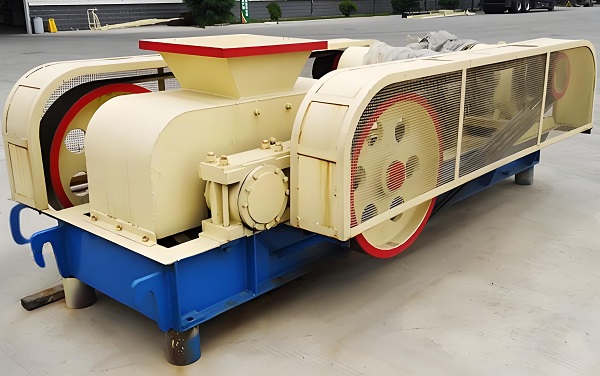

In numerous industrial sectors such as mining, construction materials, and chemical processing, crushing equipment has always played a fundamental role. The double-roll crusher, as a long-established and technologically mature crushing machine, holds an irreplaceable position in crushing medium-to-low hardness materials due to its unique structural advantages. Also known as a twin-roll crusher, its core working principle involves using a pair of relatively rotating rollers to crush materials to the required particle size through the extrusion and shearing forces of the roller surfaces. A thorough understanding of its structural composition and performance characteristics is of significant practical importance for rational selection, optimized operation, and improved production efficiency.

A. Structural Composition of a Double-Roll Crusher

The structural design of the double-roll crusher follows the principles of "simplicity, efficiency, and ease of maintenance." It consists of six core parts: the main frame, the crushing roller system, the transmission system, the adjusting device, the safety protection device, and the lubrication system. These components work together to complete the material crushing operation. These structural components have been continuously optimized through long-term technological iteration, retaining the stability of traditional equipment while incorporating advanced concepts from modern mechanical design.

1. Main Frame: The Load-Bearing Foundation of the Equipment

As the "skeleton" of the double-roll crusher, the main frame primarily bears the weight of core components such as the crushing roller system and transmission system. It also withstands the enormous impact and compressive forces generated during material crushing, thus requiring extremely high strength and rigidity. The main frame is typically constructed from welded structural steel or integrally cast cast steel. Larger models often use cast steel structures to ensure overall structural stability; smaller and medium-sized models primarily use welded high-quality structural steel to reduce manufacturing costs while maintaining strength. The frame's structural design features a symmetrical layout with pre-drilled, precise mounting holes for fixing bearing seats and adjustment devices, ensuring the installation accuracy of the crushing rollers and preventing malfunctions due to assembly deviations. Furthermore, the frame is usually equipped with protective covers to prevent material splashing during crushing, thus avoiding safety hazards, and to effectively isolate dust, improving the working environment.

2. Crushing Roller System: Core Crushing Actuator

The crushing roller system is the core component of a roll crusher for material crushing. It consists of two parallel crushing rollers. Depending on the roller surface type, they can be divided into smooth rollers, toothed rollers, and grooved rollers, each suitable for crushing materials with different characteristics. Each crushing roller consists of a roller body, roller shaft, bearings, and bearing housing. As the component in direct contact with the material, the material selection of the roller body directly affects the crushing efficiency and service life of the equipment. For crushing materials with low hardness (such as limestone and coal gangue), the roller body is often made of high-manganese steel or wear-resistant alloy steel. For crushing materials with strong corrosiveness or slightly higher hardness, a wear-resistant alloy layer is welded onto the roller body surface to further improve its wear resistance.

The crushing rollers can be installed in two ways: fixed rollers and movable rollers. The bearing housing of a fixed roller is rigidly fixed to the frame and its position remains unchanged. The bearing housing of a movable roller is installed on a sliding guide rail of the frame and can be moved horizontally through an adjustment device, thereby changing the gap between the two rollers to control the particle size of the crushed material. This "fixed-one-flexible" layout design ensures the stability of the crushing process while providing convenient conditions for particle size adjustment.

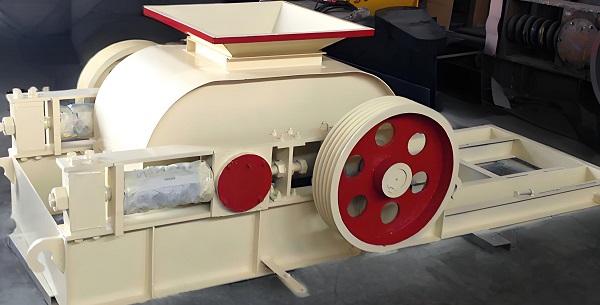

3. Transmission System: The Core of Power Transmission

The transmission system's function is to smoothly and efficiently transmit the motor's power to the crushing rollers, driving them to rotate relative to each other at a set speed to complete the material crushing operation. The transmission system of a double-roll crusher typically adopts a "motor-reducer-coupling-crushing roller" transmission mode. Some smaller equipment may use a V-belt direct drive to simplify the structure and reduce costs. The motor, as the power source, requires power selection based on parameters such as the equipment model, the hardness of the material to be crushed, and the processing capacity, ensuring sufficient and stable power output. The reducer converts the high-speed rotation of the motor into the low-speed, high-torque rotation required by the crushing rollers through a gear reduction mechanism. Commonly used reducer types include cylindrical gear reducers and bevel gear reducers, with cylindrical gear reducers being widely used due to their simple structure and ease of maintenance.

To ensure that the two crushing rollers rotate synchronously and in opposite directions, a pair of meshing synchronous gears are usually installed in the transmission system. These synchronous gears are typically mounted at the ends of the crushing rollers and fixed to the roller shaft via a key. This synchronous transmission design effectively avoids uneven material crushing or accelerated roller surface wear caused by inconsistent roller speeds, while also reducing vibration and noise during equipment operation.

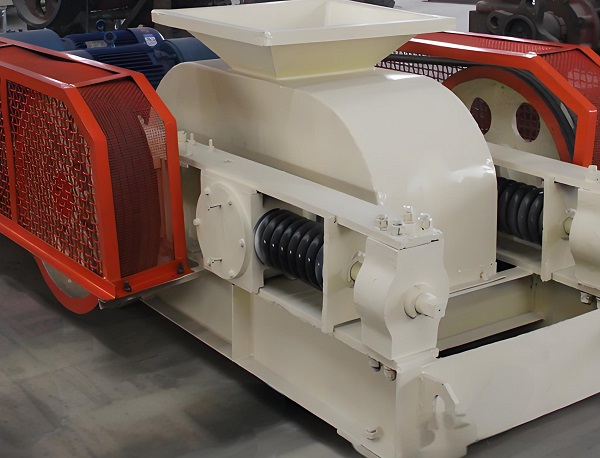

4. Adjustment Device: Key to Particle Size Control

The adjustment device is a crucial component for achieving precise control of the crushed product's particle size. Its core function is to adjust the degree of material crushing by changing the gap between the movable and fixed rollers. Currently, there are two main adjustment methods: The first is shim adjustment, which changes the distance between the two rollers by adding or removing shims of different thicknesses between the movable roller bearing housing and the frame. This method is simple in structure and highly reliable, but the adjustment process is relatively cumbersome, requiring manual operation after machine shutdown. It is suitable for scenarios where the crushed particle size does not change frequently. The second is hydraulic adjustment, which uses a hydraulic cylinder to push the movable roller along the guide rail. Precise adjustment of the gap is achieved through pressure control of the hydraulic system. Some advanced equipment is also equipped with an electro-hydraulic control system, enabling remote automated adjustment. This not only has high adjustment efficiency but also allows for real-time adjustments according to production needs, making it suitable for continuous and highly automated production lines.

The accuracy of the adjustment device directly determines the particle size uniformity of the crushed product. Therefore, the machining and positioning accuracy of its guide rails are required to be high. Grinding processes are typically used to ensure smooth and unobstructed movement of the movable roller, with the gap adjustment error controlled within 0.1mm.

5. Safety Protection Devices: Ensuring Operational Safety

Considering potential emergencies during crushing operations (such as the introduction of foreign metal objects, material overload, etc.), double-roll crushers must be equipped with comprehensive safety protection devices to prevent equipment damage and personnel injury. Common safety protection devices include overload protection and foreign object protection. Overload protection is typically achieved through safety pins or hydraulic safety devices installed in the transmission system. When the crushing roller encounters an overload, the safety pin will shear off, or the hydraulic system's overflow valve will open, promptly cutting off power transmission and protecting core components such as the motor, reducer, and crushing roller from damage. Foreign object protection often employs a combination of electromagnetic separators and metal detectors. Before material enters the crushing chamber, the electromagnetic separator removes most magnetic metal foreign objects, and the metal detector detects non-magnetic metal foreign objects. Once a foreign object is detected, the system immediately issues an alarm and shuts down, allowing operators to remove it promptly.

Furthermore, protective covers are installed on the transmission parts of the equipment, and safety guardrails are installed above the crushing chamber to further enhance the safety of equipment operation and meet industrial production safety regulations.

6. Lubrication System: Extending Equipment Lifespan

The rotating parts of a double-roll crusher (such as bearings and synchronous gears) generate intense friction during high-speed operation. Poor lubrication can easily lead to wear, overheating, and even equipment failure. Therefore, a robust lubrication system is crucial for ensuring the long-term stable operation of the equipment. A lubrication system typically consists of an oil tank, oil pump, filter, oil pipes, and nozzles. Depending on the equipment model, it can be either manual or automatic lubrication. Smaller machines often use manual lubrication, where operators periodically add lubricating oil to the lubrication points via nozzles. Larger machines are equipped with automatic lubrication systems, where the oil pump automatically supplies oil to each lubrication point at set intervals, ensuring even and sufficient lubrication while reducing manual maintenance workload.

The type of lubricating oil used in the lubrication system must be selected appropriately based on the equipment's operating temperature, load, and environmental conditions. Generally, anti-wear hydraulic oil or industrial gear oil is used. Regular testing and replacement of the lubricating oil are essential to prevent lubrication failure due to oil deterioration.

B. Key Features of Double Roll Crusher

Based on its unique structural design, the double roll crusher has demonstrated numerous significant characteristics in long-term industrial applications. These characteristics give it a clear competitive advantage in the crushing of medium- and low-hardness materials, and also determine its applicable scope and application scenarios.

1. Uniform Particle Size and High Product Quality

The double roll crusher controls the particle size of the crushed product through the gap between the two rolls, offering high adjustment precision. The crushing process primarily relies on extrusion pressure, resulting in a concentrated particle size distribution, low fine powder content, and relatively regular particle shape, typically cubic or near-circular, avoiding over-crushing. This uniform particle size characteristic is extremely beneficial for subsequent screening and grinding processes, effectively improving the efficiency and product quality of the entire production line. For example, in the coal industry, using a double roll crusher to crush raw coal yields uniformly sized clean coal particles, reducing coal resource waste; in the building materials industry, when crushing limestone for cement production, the uniform particle size ensures sufficient calcination of the cement raw materials, improving cement strength.

2. Low Energy Consumption and Low Operating Costs

Compared to other crushing equipment such as jaw crushers and cone crushers, double roll crushers have higher crushing efficiency and lower unit energy consumption. This is because the crushing process in a double roll crusher involves the material directly entering the crushing chamber between the two rolls, resulting in concentrated and direct compressive force and less energy loss. Other crushing equipment often uses impact or compression crushing, where the material undergoes multiple collisions and friction within the crushing chamber, leading to greater energy loss. Statistics show that, for the same processing capacity, the unit energy consumption of a double roll crusher is 20% to 30% lower than that of a jaw crusher. Furthermore, due to its simple structure, long service life of vulnerable parts (such as the rolls), and long maintenance cycles, maintenance costs are low, further reducing the overall operating cost of the equipment, making it suitable for long-term continuous use by small and medium-sized enterprises.

3. Simple Structure and Convenient Operation and Maintenance

Double roll crushers have fewer core components and a compact structural layout. They lack complex transmission mechanisms and crushing chamber structures, making it easy for operators to understand and master the working principle and operation methods of the equipment. The equipment is relatively simple to start, stop, and adjust in terms of particle size, allowing even inexperienced operators to quickly learn how to use it. Maintenance is straightforward; easily worn parts are convenient to replace. For example, worn roller surfaces can be repaired by welding or the roller sleeve can be replaced directly without disassembling the entire machine. Lubrication system maintenance only requires periodic checks of oil levels and quality, and filter replacement, significantly reducing maintenance workload and downtime, thus improving the equipment's effective operating rate.

4. Stable Operation, Low Noise and Vibration

Due to the "one fixed, one movable" crushing roller layout and the synchronous gears in the transmission system, the two rollers maintain stable speeds and coordinated directions during operation, avoiding resonance caused by component vibration. Furthermore, the crushing process is completed within a closed crushing chamber, and the rigid structure of the frame effectively absorbs some vibration and noise. Therefore, the noise and vibration levels during operation are significantly lower than other types of crushing equipment. Under normal circumstances, the operating noise of a double roll crusher can be controlled below 85 decibels, and the vibration amplitude is less than 2 mm. This not only improves the working environment for operators but also reduces the impact of equipment vibration on surrounding buildings and other equipment, meeting the environmental protection requirements of modern industrial production.

5. Wide Applicability and Strong Adaptability

By changing the crushing rollers with different surface types and adjusting the gap between the two rollers, the double roll crusher can adapt to the crushing needs of various medium-to-low hardness materials, such as coal, limestone, gypsum, shale, bentonite, and fertilizer raw materials. For brittle materials, smooth rollers can be used to achieve crushing through extrusion pressure; for materials with high viscosity or prone to agglomeration, toothed rollers can be used, utilizing the combined action of shearing and extrusion forces to prevent material adhesion on the roller surface; for materials requiring a specific particle size distribution, customized crushing can be achieved through precise adjustment of the gap. Furthermore, the double roll crusher has a wide processing capacity range, from small laboratory equipment (0.5~1 t/h) to large industrial equipment (100~200 t/h), meeting the needs of different scales of production and demonstrating strong adaptability. 6. Excellent Environmental Friendliness and Low Pollution

In today's increasingly stringent environmental regulations, the environmental advantages of double-roll crushers are becoming increasingly prominent. On one hand, the crushing chamber of the equipment adopts a closed design, coupled with a protective cover on the outside of the frame, which effectively prevents dust generated during material crushing from escaping. On the other hand, the equipment operates with low noise and vibration, eliminating the need for additional complex noise reduction and vibration damping equipment. Some advanced double-roll crushers also have a dust collection interface above the crushing chamber, connecting to the workshop's dust collection system to further reduce dust pollution. Compared with traditional impact crushers, double-roll crushers can reduce dust emissions by more than 50% and noise by 10-15 decibels, meeting national environmental standards and providing strong support for enterprises to achieve green production.

With its core advantages of "simple structure, convenient operation, low energy consumption, and excellent environmental friendliness," the double-roll crusher has always maintained strong vitality in the field of crushing medium and low hardness materials. The coordinated operation of its six core structures—main frame, crushing roller system, transmission system, etc.—ensures stable operation and efficient crushing. Its outstanding features, such as uniform product particle size, low operating costs, and wide applicability, have led to its widespread use in various industries including mining, building materials, and chemicals. With the continuous development of modern mechanical manufacturing and automation control technologies, double roll crushers are also upgrading towards larger scale, higher intelligence, and greater wear resistance. In the future, their crushing efficiency and reliability will be further improved, providing stronger support for high-quality industrial production. For enterprises, a thorough understanding of the structure and characteristics of double roll crushers, combined with reasonable selection based on their own production needs, will enable them to fully leverage the equipment's performance advantages and achieve a dual improvement in production efficiency and economic benefits.

Save Time! Get A Detailed Quotation Quickly.