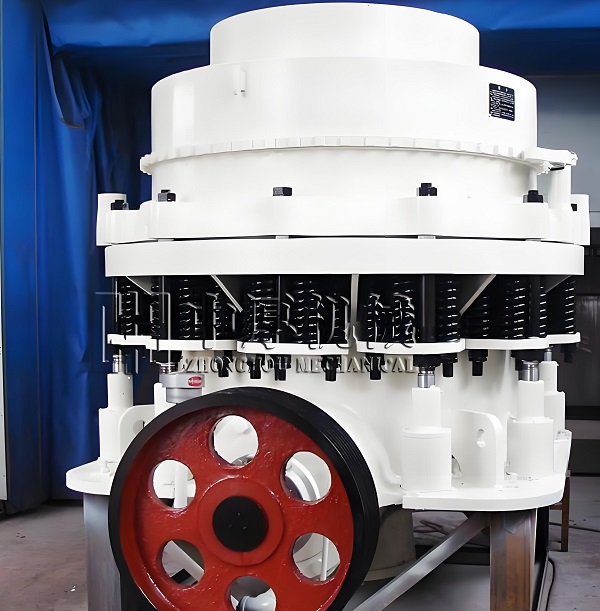

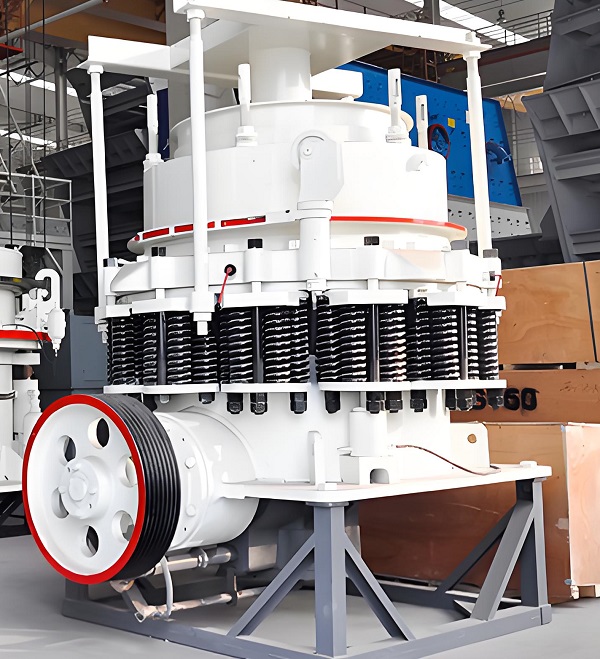

In crushing operations in industries such as mining, construction, and metallurgy, the spring cone crusher, a classic and highly efficient crushing equipment, has long held a prominent position thanks to its unique structural design and stable performance. Using a spring mechanism as its core protective and regulating component, combined with the principle of laminated crushing, it efficiently crushes medium-to-high-hardness materials such as granite, basalt, and iron ore. While maintaining the crushing advantages of traditional cone crushers, it also achieves breakthroughs in safety, adaptability, and ease of operation through the innovative design of its spring system, making it a preferred choice for many industrial crushing applications.

Basic Features of the Core Structural Support

The unique characteristics of a spring cone crusher stem primarily from its scientific structural design. The coordinated operation of its various components ensures both efficient crushing and stable and reliable operation. This can be specifically demonstrated in the following three aspects:

1. Spring System: Serving Both Protective and Regulating Functions

The spring mechanism is the core hallmark of the spring cone crusher and a key feature that distinguishes it from other types of cone crushers. The equipment features multiple sets of high-strength springs evenly spaced beneath or around the fixed cone (adjustment sleeve). These springs serve not simply as support components but also as overload protection and fine-tuning the discharge opening. When uncrushable foreign matter (such as iron or rebar) enters the crushing chamber, the springs compress, pushing the fixed cone upward and instantly widening the discharge opening, allowing the foreign matter to be discharged smoothly and preventing damage to core components such as the crushing teeth and main shaft from severe impact. Once the foreign matter is discharged, the springs return to their original position due to their inherent elasticity, allowing the fixed cone to return to its original position and allowing the equipment to resume normal crushing without shutting down, significantly reducing the risk of downtime caused by stalling or material jamming. Furthermore, by adjusting the spring preload, the discharge opening size can be indirectly fine-tuned to meet the crushing requirements of different particle sizes. This allows for flexible operation without disassembling complex components.

2. Laminated Crushing Chamber: An Efficient Structure Suitable for High-Hardness Materials

The spring cone crusher's crushing chamber utilizes a "progressive laminated crushing" design. Chamber types are available in standard, medium, and short-head configurations, depending on material hardness and the desired crushing requirements (coarse, medium, or fine). The coarse crushing chamber features steeply inclined walls and a wide feed opening, allowing for larger materials (maximum feed size over 800mm). The fine crushing chamber has steeper walls and a longer crushing zone, enabling multiple compression and grinding of the material. This chamber design eliminates a single force applied to the material within the crushing chamber, trapping it between the moving and fixed cones. This laminated action achieves "multi-particle mutual compression and crushing," reducing direct wear on the crushing plates and preventing over-crushing (lowering the fines content). The resulting crushed product is uniform in size and has a high proportion of cubic shapes, making it particularly suitable for construction aggregate production applications where strict requirements on final particle shape are crucial.

3. Stable Transmission and Sealing: Ensuring Long-Term Continuous Operation

Spring cone crushers typically utilize a "motor + V-belt + bevel gear" transmission system. Motor power is transmitted via the V-belt to the horizontal shaft, which in turn drives the vertically mounted main shaft and rotating cone. This transmission method offers high efficiency (transmission loss is less than 5%), and the V-belt provides a certain cushioning effect, reducing shock during motor startup and protecting the motor and gear components. Furthermore, the equipment's sealing system often utilizes a "labyrinth seal + dust ring" combination design, effectively preventing dust generated during the crushing process from entering the bearings and transmission components, preventing lubricant contamination, extending bearing life (under normal maintenance, bearing life can reach over 8,000 hours), and reducing downtime caused by seal failure.

Core Advantages of Adapting to Industrial Needs

Based on these structural features, spring cone crushers demonstrate numerous advantages in practical applications, meeting the crushing challenges of various industries. They excel in crushing medium- and high-hardness materials, ensuring continuous operation stability, and achieving cost control.

1. Strong crushing capacity for high-hardness materials and wide adaptability. One of the core advantages of a spring cone crusher is its wear and impact resistance. Its crushing plates are made of high-manganese steel (ZGMn13) or high-chromium cast iron, achieving a surface hardness of HRC50-60. This allows it to withstand the long-term compression and friction of medium- to high-hardness materials (Mohs hardness 6-10, such as granite, basalt, iron ore, and quartz). Compared to a jaw crusher, its laminated crushing principle distributes the crushing force across multiple material particles, preventing damage to the plates caused by localized stress concentration. Furthermore, the overload protection of the spring system further reduces the risk of foreign matter contamination in high-hardness materials. Whether for coarse ore crushing in mining, fine ore crushing in the metallurgical industry, or aggregate production in the construction industry, spring cone crushers offer stable operation. Especially in metal ore crushing, their uniform crushed product size can directly meet the feed requirements of ball mills (for example, the particle size of crushed iron ore can be controlled to 20-50mm), reducing energy consumption in subsequent grinding processes.

2. High operational stability and outstanding continuous operation capability

Industrial crushing applications place extremely high demands on equipment's "continuous operating time." Spring cone crushers, through structural optimization, offer exceptional stability. Firstly, the rigid connection between the cone and the main shaft ensures a precise cone rotation trajectory (the eccentricity can be adjusted according to crushing requirements). This evenly distributes force within the crushing chamber, preventing vibration caused by cone sway (the amplitude is typically less than 0.5mm during operation), and minimizing impact on the foundation. Furthermore, the spring system's automatic reset function eliminates the need for equipment downtime when encountering foreign objects, significantly improving continuous operation. According to industry statistics, spring cone crushers can achieve an annual operating time of over 7,000 hours, far exceeding that of some crushing equipment (such as hammer crushers) that require frequent downtime for cleaning. They are particularly suitable for 24-hour production environments, such as large mines and building materials factories.

3. Convenient Operation and Maintenance, Reducing Labor and Time Costs

Compared to the complex structure of hydraulic cone crushers, spring cone crushers offer a lower maintenance threshold and are more suitable for small and medium-sized enterprises or those with limited technical staff. During routine maintenance, replacing the crushing teeth simply requires adjusting the spring preload to loosen the fixed cone. No complex components like the hydraulic cylinder need to be disassembled, and this can be accomplished by a single person using simple tools. This reduces replacement time to 2-3 hours (compared to the typical 4-6 hours for hydraulic cone crushers). The equipment's lubrication system utilizes a centralized lubrication design, with lubricant automatically pumped to key components such as bearings and gears. Operators only need to regularly check the oil level and quality, eliminating the need for individual refills, thus reducing maintenance workload. Furthermore, spring cone crushers have a limited number of wearing parts (primarily crushing teeth, bearings, and seals), resulting in low procurement costs and ample market supply, further reducing equipment operation and maintenance costs.

4. Low investment cost and significant cost-effectiveness

From the perspective of equipment procurement and lifecycle costs, spring cone crushers offer significant cost-effectiveness advantages. First, their relatively simple structure (no complex hydraulic or electronic control systems) results in low manufacturing costs. For the same specifications, spring cone crushers are 30%-50% cheaper than hydraulic cone crushers, making them more suitable for small and medium-sized enterprises with limited budgets. Second, due to their high lamination crushing efficiency, spring cone crushers require 15%-20% less motor power than jaw crushers for the same crushing output (e.g., crushing 100 tons of granite per hour), saving tens of thousands of kilowatt-hours of annual electricity consumption. Finally, their low replacement costs for wearing parts and long maintenance cycles mean that lifetime operating and maintenance costs are only 60%-70% of those for hydraulic cone crushers. This effectively reduces production costs for businesses over the long term.

5. Excellent crushed product quality meets demanding applications

Spring cone crushers offer significant advantages in applications requiring high-precision crushed product shape and size, such as in the production of high-quality concrete aggregate and road base materials. Their laminated crushing principle allows the material to undergo multiple compression and grinding cycles within the crushing chamber, shaping the particles. The resulting product contains less than 5% needle-shaped particles (compared to 10%-15% in a jaw crusher), while cubic particles account for over 80%, meeting the requirements for Class I aggregate in GB/T 14685-2022, "Pebbles and Crushed Stone for Construction." Furthermore, by adjusting the spring preload and the eccentricity of the moving cone, the discharge opening size can be precisely controlled (typically within a range of 5-100mm), achieving a range of particle sizes from coarse to fine crushing. This eliminates the need for additional shaping equipment, reducing production steps and equipment investment. For example, in highway construction, basalt aggregate crushed by a spring cone crusher can be directly used in asphalt concrete pavement, enhancing the strength and durability of the road surface.

Applicable Scenarios and Extended Application Value

The characteristics and advantages of spring cone crushers make them irreplaceable in multiple industries. In the mining industry, they serve as secondary crushing equipment for metal ores such as iron ore and copper ore, providing raw materials of the appropriate particle size for subsequent beneficiation processes. In the construction and building materials industry, they are used to crush materials such as granite and limestone to produce high-quality concrete aggregate and dry mortar raw materials. In the metallurgical industry, they can crush industrial solid waste such as steel slag and iron slag, achieving resource recycling. Even as hydraulic cone crushers become increasingly popular, spring cone crushers, with their high reliability, low investment cost, and easy maintenance, continue to hold a key position in small and medium-sized crushing production lines, remote mines (where maintenance is limited), and for crushing high-hardness materials. They have become a classic device in the industrial crushing industry, offering both cost-effectiveness and practicality.

The spring cone crusher takes the spring system as its core and combines the laminated crushing principle. It has strong crushing ability and stable operating performance, and excels in cost control and operation and maintenance. It can not only meet the crushing needs of medium and high hardness materials, but also adapt to the production scenarios of enterprises of different sizes. Its application value in the field of industrial crushing comes from its precise fit with the core needs of "efficiency, reliability and economy". It is still an important option for many companies in the selection of crushing equipment.

Save Time! Get A Detailed Quotation Quickly.