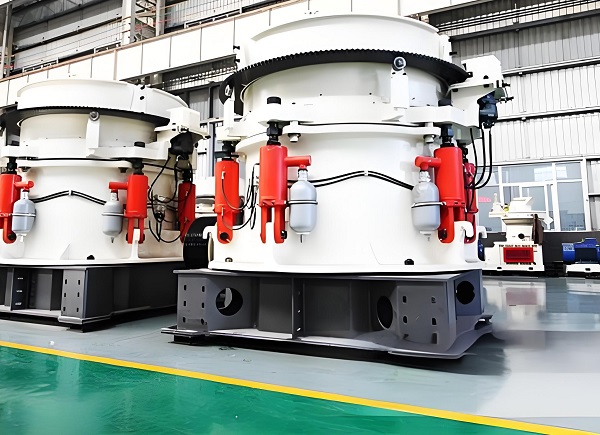

In crushing operations in industries such as mining, construction, and metallurgy, hydraulic cone crushers, thanks to their unique technical design and superior performance, are gradually replacing traditional crushing equipment and becoming a core component for medium and fine crushing. With the hydraulic system as its core control unit and incorporating the principle of laminated crushing, they demonstrate significant advantages in processing high-hardness, highly abrasive materials such as granite, basalt, and iron ore. They meet the demands of efficient production while balancing crushed product quality and equipment operational stability. Their features and advantages can be analyzed in depth from multiple perspectives, including technical design, operational performance, operation and maintenance, and application compatibility.

Technical Design: Precision Structure, Powered by a Core Hydraulic System

The core competitiveness of the hydraulic cone crusher stems from its sophisticated structural design, particularly the deep integration of the hydraulic system and crushing mechanism. This overcomes the performance limitations of traditional spring cone crushers and achieves the technical characteristics of "stability, reliability, and strong controllability."

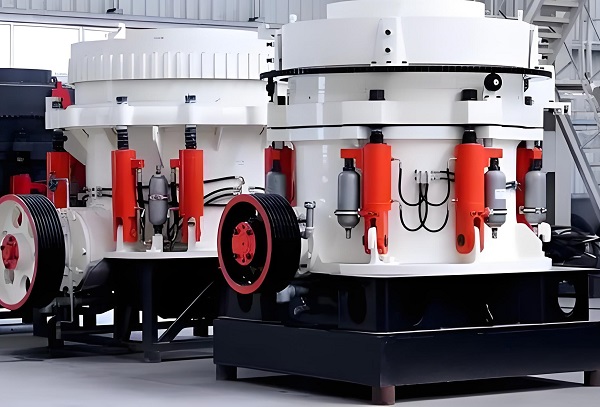

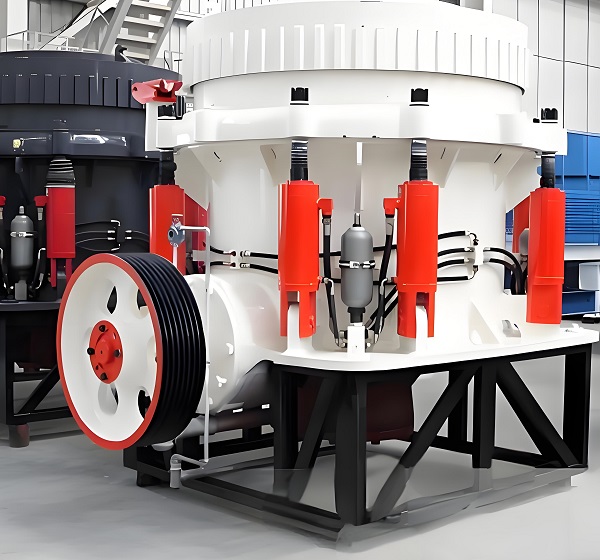

Overall, it consists of four main components: the crushing unit, the hydraulic control system, the lubrication system, and the electrical control system. The coordinated design of these components highlights meticulous craftsmanship. The crushing main unit utilizes a "fixed main shaft, rotating eccentric sleeve" structure: the main shaft is mounted vertically at the bottom of the frame, with its top end rigidly connected to the crushing cone (moving cone). The eccentric sleeve, driven by a motor, rotates around the main shaft, driving the moving cone in a periodic oscillating motion. This, combined with the fixed cone fixed to the frame, forms a continuously changing crushing chamber, squeezing, bending, and grinding the material. Compared to traditional crushers, this structure reduces the impact load on moving parts, provides more uniform force distribution on the main shaft, and enhances overall rigidity, allowing it to withstand higher crushing pressures.

The hydraulic system, the "core brain" of the equipment, is a key design highlight. This system typically consists of three modules: a hydraulic adjustment device, a hydraulic overload protection device, and a hydraulic cavity clearing device, all of which are deeply integrated with the crushing operation. The hydraulic adjustment device precisely controls the size of the discharge opening between the movable and fixed cones by adjusting the extension and retraction of the hydraulic cylinder. The adjustment range of the discharge opening can be refined to 0.1mm, flexibly adapting to crushing tasks with different particle size requirements. The hydraulic overload protection device monitors the pressure in the crushing chamber in real time. When encountering uncrushable foreign matter (such as iron or steel blocks), the system quickly relieves pressure, pushing the movable cone away from the fixed cone, providing a discharge channel for the foreign matter. This prevents serious failures such as spindle breakage and gear damage caused by "material jamming" in traditional equipment. The hydraulic cavity clearing device uses hydraulic thrust to eject residual material from the crushing chamber during equipment shutdown or crushing chamber replacement, significantly reducing cavity clearing time and addressing the low efficiency and high labor intensity of manual cavity clearing in traditional equipment.

In addition, the equipment's lubrication system utilizes a "forced circulation + constant temperature control" design. Lubricating oil is forcibly pumped to the friction surfaces of key moving components, such as the main shaft and eccentric sleeve, via an oil pump, forming a uniform oil film. Simultaneously, a cooler stabilizes the lubricating oil temperature within the optimal range of 35-45°C, preventing lubrication failure caused by high temperatures and significantly extending the service life of vulnerable parts such as bearings and gears.

Operational Performance: High Efficiency and Energy Saving, Excellent Crushing Quality and Stability

In actual crushing operations, the performance advantages of hydraulic cone crushers are concentrated in three aspects: efficient crushing, high-quality finished products, and low energy consumption and stability, effectively improving the overall efficiency of the production line.

1. High Crushing Efficiency, Suitable for High-Hardness Materials

Thanks to the application of the laminated crushing principle, the hydraulic cone crusher's crushing chamber design features a "gently inclined, large meshing angle" structure. Materials undergo multiple compression and grinding processes within the crushing chamber, rather than a single impact crushing. This crushing method not only crushes materials more thoroughly but also ensures more even filling of the crushing chamber, reducing empty hits. Compared to traditional spring cone crushers, its processing capacity can be increased by 15%-30%. Furthermore, the crushing force of the equipment can be flexibly adjusted via the hydraulic system. For high-hardness materials with a hardness of 7 or above on the Mohs scale (such as basalt and quartzite), the crushing pressure can be increased to 30-50 MPa, ensuring thorough crushing and avoiding the problem of excessively coarse material due to insufficient crushing force. This meets the crushing needs of industries such as mining and construction aggregates for high-hardness materials.

2. Uniform finished product particle size and high-quality particle shape

For crushing operations, the particle size and shape of the finished material directly impact the quality of subsequent processing (such as sand making and concrete mixing). Hydraulic cone crushers utilize two key design features to ensure the quality of their finished products. First, the aforementioned "precise discharge opening control" ensures that the hydraulic system compensates for any enlargement of the discharge opening caused by liner wear, ensuring that discharge particle size fluctuations are controlled within ±0.5mm, thus preventing uneven coarse and fine finished product particle sizes. Second, the advantage of the laminated crushing method—the compression and friction of materials within the crushing chamber smooths out surface roughness, resulting in a more cubic shape and a flake content below 5% (compared to the typical 10%-15% in conventional crushers). For example, granite aggregate crushed with a hydraulic cone crusher produces a full, well-graded particle shape, significantly improving the strength and workability of concrete, meeting the material requirements of high-standard projects such as high-speed railways and bridges.

3. Low Energy Consumption and Strong Operational Stability

In terms of energy efficiency, the hydraulic cone crusher's low energy consumption stems primarily from two key factors. First, its motor power is more closely matched to its processing capacity. Through flexible hydraulic system control, the motor avoids inrush current during startup and automatically adjusts output power when the crushing load fluctuates, avoiding energy waste caused by a "big horse pulling a small cart." Compared to conventional crushers of the same processing capacity, energy consumption can be reduced by 10%-20%. Second, the laminated crushing method reduces direct impact between the material and the liner, slowing liner wear and extending the liner replacement cycle to 3-6 months (compared to 1-2 months for conventional equipment). This not only reduces the cost of wearing parts but also reduces the energy consumption associated with downtime due to liner replacement.

The hydraulic overload protection system plays a key role in operational stability. When a conventional spring crusher encounters foreign matter, the spring's limited cushioning capacity can easily lead to problems such as spindle bending and liner breakage. However, the overload protection response time of a hydraulic cone crusher is only 0.1-0.3 seconds, instantly relieving pressure and protecting the equipment. The equipment's electrical control system is equipped with multi-dimensional sensors for temperature, pressure, and vibration, enabling real-time monitoring of parameters such as spindle temperature, lubricating oil pressure, and vibration amplitude. If an anomaly (such as excessive lubricating oil temperature or excessive vibration amplitude) occurs, the system automatically issues an alarm and shuts down the machine, preventing the malfunction from escalating. According to industry statistics, the mean time between failures (MTBF) of hydraulic cone crushers can reach over 8,000 hours, far exceeding the 5,000 hours of traditional spring cone crushers, significantly improving the continuous operation capacity of the production line.

Operation and Maintenance: Highly Intelligent, Low Labor Costs

With the advancement of industrial automation, the intelligent design of hydraulic cone crushers has significantly reduced the difficulty of operation and maintenance, reducing reliance on manual experience and becoming one of their key advantages.

1. Convenient Operation and Intelligent Control

Modern hydraulic cone crushers are commonly equipped with PLC intelligent control systems. Operators can use the touchscreen to control functions such as one-touch start and stop, parameter setting, and status monitoring. Simply input parameters such as the target discharge size and processing volume, and the system automatically adjusts the hydraulic pressure and feed rate, achieving automated control of the crushing process. The touchscreen also displays real-time operating parameters (such as motor current, discharge opening size, and lubricating oil temperature) and presents historical operating data in graphical form, allowing operators to analyze production efficiency and equipment status. Some high-end models also support remote monitoring, transmitting device data to a cloud-based management platform via IoT technology. This allows managers to view equipment status in real time from their office and even adjust parameters remotely, eliminating the need to be on-site at the dusty and noisy crushing site, improving the operating environment.

2. Easy Maintenance and Low Repair Costs

The maintenance advantages of hydraulic cone crushers primarily lie in the ease of replacing wearing parts and the streamlined repair process. For replacement of wearing parts, the crushing liners are secured with hydraulic fastening, rather than traditional bolts. To replace a liner, the hydraulic system simply loosens the fastening cylinder to remove the old liner, a process that takes only 2-3 hours (compared to 4-6 hours for traditional equipment). Furthermore, the lubrication system features automatic filtration and oil level monitoring. If impurities in the lubricating oil exceed the specified limit or the oil level is too low, the system automatically generates an alarm, reducing the need for manual inspections.

In terms of maintenance, the modular design of the hydraulic system enables more efficient troubleshooting. For example, if the equipment encounters a discharge port adjustment failure, the operator can view pressure data from the hydraulic adjustment module via the PLC system and quickly determine whether the cause is a cylinder leak or a solenoid valve failure, without disassembling the entire hydraulic system. Furthermore, some models feature maintenance access and observation windows, allowing operators to directly observe the interior of the crushing chamber and inspect components such as the main shaft and eccentric sleeve, further simplifying maintenance. Overall, the annual maintenance cost of a hydraulic cone crusher is 25%-35% lower than that of traditional equipment, while also reducing downtime due to maintenance.

Application Compatibility: Wide Coverage, Flexible Response to Diverse Demands

The design features of hydraulic cone crushers make them highly adaptable to various applications, allowing them to flexibly adapt to changes in material properties, production scale, and finished product requirements. They are widely used in a variety of industries, including mining, construction, metallurgy, and chemicals.

In terms of material compatibility, they not only efficiently process hard rock materials such as granite, basalt, and iron ore, but also adapt to the crushing needs of medium- and low-hardness materials such as limestone and sandstone by changing the liner of different chamber types (such as standard, medium, and fine chambers). The standard chamber is suitable for secondary crushing after coarse crushing, with a high throughput; the fine chamber is suitable for tertiary crushing, producing a finer finished product size (down to 5mm or less). For example, in iron ore crushing production lines in metal mines, the fine chamber of a hydraulic cone crusher can crush iron ore to less than 10mm, reducing energy consumption in the subsequent ball mill grinding process. In construction aggregate production, the standard chamber type enables integrated coarse and secondary crushing, streamlining the production line.

Hydraulic cone crushers offer a wide range of processing capacities, from small 50 t/h models to large 1,500 t/h and above, meeting the needs of production lines of varying sizes. Smaller equipment is suitable for small quarries in rural areas and construction demolition waste disposal stations, while larger equipment can complement the complete "coarse crushing (jaw crusher) + medium and fine crushing (hydraulic cone crusher) + sand making" production lines of large mines. For example, a large iron ore mine utilizes three 800 t/h hydraulic cone crushers, achieving a daily processing capacity of 20,000 tons of iron ore and ensuring raw material supply for subsequent smelting processes.

Furthermore, with increasingly stringent environmental protection requirements, the low noise and low dust characteristics of hydraulic cone crushers make them particularly well-suited for green production. The equipment's semi-enclosed crushing chamber reduces dust escape. Furthermore, the uniform meshing clearance between the moving and fixed cones reduces metal-to-metal noise, keeping operating noise below 85 decibels (compared to 95-100 decibels for conventional equipment). This meets national noise emission standards for industrial plants and helps companies achieve "green crushing."

The hydraulic cone crusher, with precision hydraulic control at its core, integrates the principles of laminated crushing with intelligent design. It offers significant advantages in terms of technical structure, operational performance, operation and maintenance, and application compatibility. It not only addresses the pain points of traditional crushing equipment, such as low efficiency, poor product quality, and frequent failures, but also adapts to the diverse needs of various industries, providing strong support for efficient production and green development in sectors such as mining and construction. With the continuous advancement of hydraulic and intelligent control technologies, hydraulic cone crushers will continue to develop towards greater efficiency, intelligence, and energy efficiency, further consolidating their core position in the crushing equipment market.

Save Time! Get A Detailed Quotation Quickly.