Preface: In many basic industrial fields such as mining, building materials production, and road construction, crushing operations are undoubtedly the key link. As a crushing equipment with a long history and wide application, the jaw crusher occupies an irreplaceable and important position in the crushing industry with its unique performance characteristics and significant advantages. Next, let us deeply analyze the excellence of the jaw crusher and explore the reasons why it is so popular in various industries.

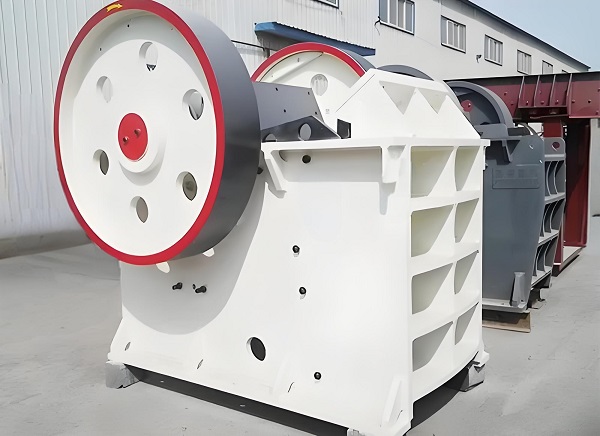

Jaw Crusher

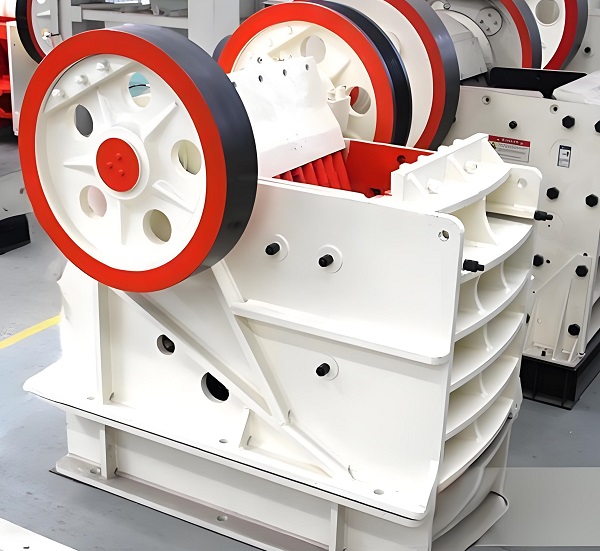

The working principle of the jaw crusher is based on the coordinated movement of the movable jaw and the static jaw. The motor drives the eccentric shaft to rotate through the pulley, driving the movable jaw to perform periodic reciprocating motion. When the movable jaw approaches the static jaw, the material is subjected to multiple forces such as extrusion, splitting and bending between the two jaw plates, thereby achieving crushing; when the movable jaw leaves the static jaw, the crushed material is discharged smoothly from the discharge port under the action of gravity. This simple and efficient working method not only ensures the stable operation of the crushing process, but also lays a solid foundation for a series of excellent performances demonstrated by the jaw crusher.

A. Characteristics of jaw crusher

1. Simple structure and convenient maintenance

The structure of jaw crusher is mainly composed of frame, working mechanism, transmission mechanism, adjustment device and safety device. The overall layout is scientific and reasonable, the number of parts is streamlined, and most of the parts are regular in shape, easy to manufacture and process. This simple structural design not only effectively reduces the manufacturing cost of the equipment, but also brings great convenience to the installation, commissioning and daily maintenance of the equipment, significantly improves the reliability and stability of the equipment operation, reduces the downtime and maintenance time, and ensures the continuity of production.

2. Large crushing ratio, high efficiency and energy saving

The crushing ratio is a key indicator to measure the crushing capacity of the crusher. It reflects the ratio of the feed particle size to the discharge particle size of the crusher. The jaw crusher has a strong crushing capacity, and the crushing ratio can usually reach 4-8. Under some special models and working conditions, this value is even higher. This means that the jaw crusher can efficiently crush large-size materials into small-size products at one time, greatly reducing the number and process of crushing operations. While improving production efficiency, it effectively reduces energy consumption and production costs, bringing higher economic benefits to the enterprise.

3. Strong adaptability and wide application

The adaptability of the jaw crusher to materials is unique. Whether it is extremely hard granite and basalt, or low-hardness limestone and shale, or coal gangue, construction waste and other materials, it can easily cope with it and crush it into the required particle size accurately. Not only that, the jaw crusher can also flexibly adapt to different production scales and complex and changeable production environments. From the flexible operation of small individual mines to the large-scale production of large modern enterprises, you can find a matching jaw crusher model to meet the diverse production needs.

4. Uniform particle size and stable quality

During the crushing process, the jaw crusher gradually crushes the material between the two jaw plates through the uniform extrusion of the moving jaw and the static jaw. This unique crushing method ensures that the material is balanced in all directions, so that the particle size of the crushed product is uniform and the particle size distribution range is narrow. The uniform product particle size provides a good foundation for subsequent screening, grinding and other operations, effectively improves the efficiency of the entire production process and the stability of product quality, and provides a strong guarantee for enterprises to create high-quality products.

5. Stable operation, safe and reliable

The working mechanism of the jaw crusher is carefully manufactured with high-strength materials. After precise design and fine processing, it has excellent strength and wear resistance and can withstand long-term, high-intensity workloads. At the same time, its transmission mechanism uses advanced technology and processes to ensure that the equipment runs smoothly. In addition, the jaw crusher is also equipped with a complete safety device. When the equipment encounters overload or other abnormal conditions, the safety device can respond quickly and cut off the power in time to protect the equipment from damage, further improving the stability and safety of the equipment operation, and providing reliable protection for operators and production environment.

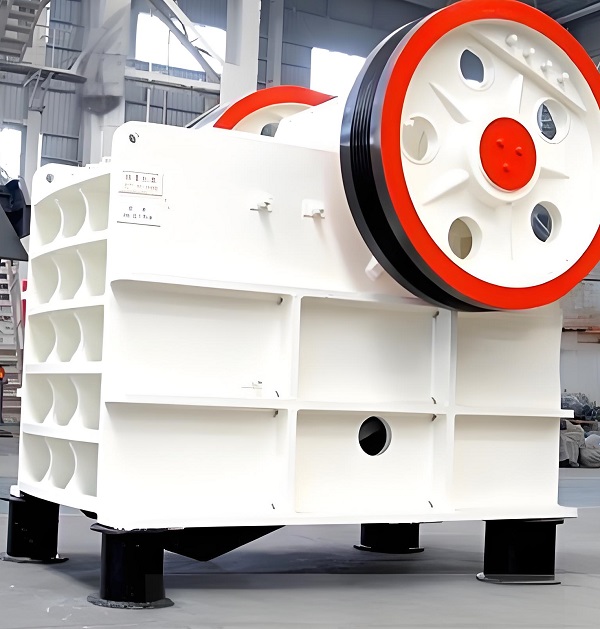

B. Advantages of jaw crusher

Jaw Crusher

1. High efficiency and high yield, guaranteed supply

Because the jaw crusher has a large crushing ratio and powerful processing capacity, it can crush a large amount of materials into the required particle size in a short time, and the production efficiency is significantly higher than similar equipment. In large-scale mining and building materials production enterprises, the jaw crusher, as a primary crushing equipment, is like a "powerful engine" of the production line, continuously providing sufficient high-quality raw materials for subsequent production links, effectively ensuring the efficient and stable operation of the entire production line and meeting the needs of large-scale production.

2. Low cost and economical

The structure of the jaw crusher is simple, with few parts, and most of the parts are easy to manufacture and replace, which greatly reduces the maintenance cost of the equipment. At the same time, its energy consumption is relatively low. Under the same production conditions, the power consumption is significantly lower than that of other types of crushers. In addition, the jaw crusher has a long service life. A jaw crusher with reliable quality can run stably for many years without frequent large-scale maintenance and replacement, which greatly reduces the life cycle cost of the equipment, saves a lot of capital investment for the enterprise, and improves the profitability of the enterprise.

3. Diverse applications and broad prospects

As mentioned above, the super adaptability of the jaw crusher to materials determines its wide range of applications. In the field of mining, it is the preferred equipment for crushing various metal ores such as iron ore, copper ore, and gold ore, providing high-quality raw materials for metal smelting; in the field of building materials production, it can be used to produce basic building materials such as limestone and sand and gravel aggregates, supporting the cornerstone of urban construction; in the field of road construction, the jaw crusher can turn abandoned concrete, asphalt and other construction waste into treasure, crushing them into recycled aggregates for the laying of road base and subbase, realizing the recycling of resources, which is in line with the trend of green development and has a broad application prospect.

4. Green environmental protection, sustainable development

As the concept of environmental protection has been deeply rooted in people's hearts, environmental protection performance has become one of the important criteria for measuring the quality of crushing equipment. In the design and manufacturing process of the jaw crusher, the concept of environmental protection is fully integrated, and a series of effective environmental protection measures have been taken. By optimizing the equipment structure and working parameters, the amount of dust generated in the crushing process can be reduced from the source; at the same time, it is equipped with an efficient dust removal device, which can collect and treat the dust generated in the production process in a timely and effective manner, greatly reducing the pollution to the environment. In addition, the jaw crusher can also achieve selective crushing of materials, accurately separate useful materials from impurities, improve resource utilization, reduce waste emissions, and provide strong support for enterprises to achieve green and sustainable development.

Jaw Crusher

5. Rich returns, investment selection

The jaw crusher has brought significant economic benefits to enterprises with its efficient production capacity, low operating costs and wide application fields. At the same time, due to its long service life, stable and reliable performance, the investment risk is relatively small, making the return on investment high. For those companies that expect to achieve long-term and stable development in the crushing industry, investing in a jaw crusher is undoubtedly a wise move, which can create rich profit returns for the company and help the company stand out in the fierce market competition.

PS: The jaw crusher has become an indispensable core equipment in the crushing industry with its many outstanding features and advantages such as simple structure, large crushing ratio, strong adaptability, uniform product particle size, stable and reliable operation, high production efficiency, low operating cost, wide application range, good environmental performance and high return on investment. With the continuous advancement and innovation of science and technology, the performance and quality of the jaw crusher will continue to improve. In the future, it will play a greater role in more fields and contribute more to promoting the sustainable development of social economy.

Save Time! Get A Detailed Quotation Quickly.