Preface: In the fields of mining, building materials processing and various industrial raw materials processing, jaw crusher (also known as jaw crusher) is an indispensable key equipment. Its performance is directly related to production efficiency, operating costs and product quality. Therefore, mastering scientific and reasonable purchasing skills is of great significance to enterprises. Next, we will discuss in depth the key points that need to be focused on when purchasing a jaw crusher.

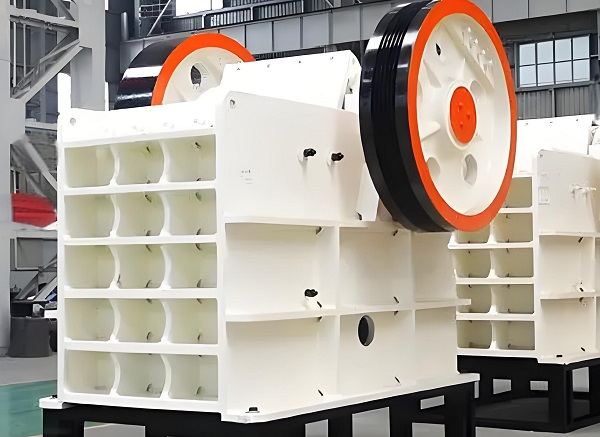

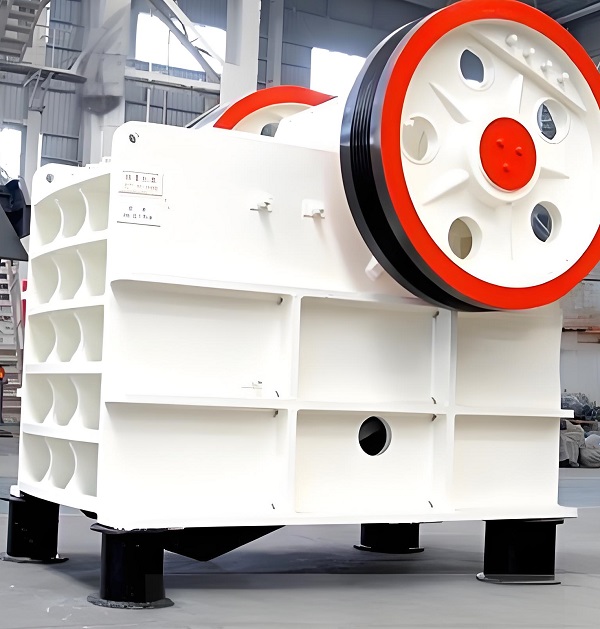

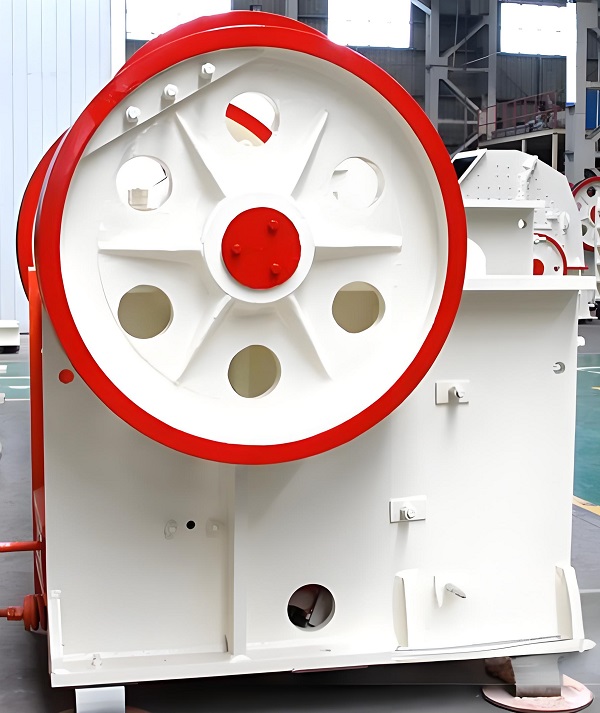

Jaw Crusher

A. Accurately locate your own needs

1. Carefully plan production capacity

It is the first task to clarify the production capacity required by yourself, that is, to determine the amount of material you expect the crusher to process per hour or per day. This requires a comprehensive consideration of the current size of the enterprise, future development strategy planning and accurate prediction of market demand. For example, if it is a small building stone processing plant, the initial production demand may be 50-100 tons per hour. As the business gradually expands, the production demand may rise to more than 200 tons per hour in the next few years. Based on such a plan, when selecting a crusher, a certain amount of capacity improvement space should be reserved to prevent frequent replacement of equipment due to insufficient production capacity in the future, which will increase additional costs.

2. In-depth analysis of material characteristics

Fully understanding the characteristics of the material to be crushed is a key link. Different materials have significant differences in physical properties such as hardness, humidity, and viscosity, which plays a decisive role in the selection of crushers. For example, for materials with higher hardness such as granite and quartz stone, it is necessary to select a jaw crusher with stronger crushing force and excellent wear resistance; and for materials with higher humidity, such as clay with higher water content, it is necessary to focus on the smoothness of the equipment's discharge to avoid material blockage in the crushing chamber, thereby affecting production efficiency. In addition, materials with high viscosity tend to adhere to the parts of the crusher, so a model that is easy to clean and maintain should be selected.

3. Clear requirements for finished product particle size

According to the purpose of the final product, accurately determine the required finished product particle size range. If the product is used as aggregate for road base paving, the particle size requirements are relatively loose; but if it is used as a raw material for the production of fine industrial products such as glass and ceramics, then the requirements for the uniformity and accuracy of the particle size will be extremely high. Although the jaw crusher can control the finished product particle size by adjusting the discharge port, different models of equipment have different particle size adjustment ranges and precisions. Therefore, before purchasing, it is necessary to clarify your own particle size requirements and fully communicate with the supplier to ensure that the selected equipment can meet the needs.

Jaw Crusher

B. Comprehensive evaluation of equipment quality

1. Strictly control material selection

The main components of the crusher, such as the movable jaw, static jaw, eccentric shaft, frame, etc., the quality of the material directly determines the service life and performance of the equipment. High-quality crushers usually use high-strength cast steel or alloy steel to manufacture the movable jaw and static jaw. Such materials have good wear resistance and toughness, and can withstand huge crushing forces without deformation and fracture. The eccentric shaft is mostly made of high-quality steel such as 45 steel or 40Cr. After quenching and tempering, it has higher strength and fatigue resistance. When inspecting the equipment, be sure to ask the supplier for detailed information about the material of each component and carefully check the relevant quality certification documents.

2. Attach great importance to manufacturing technology

Advanced manufacturing technology is an important factor in ensuring equipment quality. For example, the surface treatment process of the movable jaw and the static jaw will affect their wear resistance and corrosion resistance; the quality of the welding process determines the overall strength and stability of the frame. Some high-end jaw crushers use CNC processing technology to ensure the processing accuracy and dimensional consistency of parts, thereby improving the assembly quality and operating stability of the equipment. When purchasing, if conditions permit, you can visit the manufacturer's production workshop to observe its manufacturing process and quality control process on the spot and gain an in-depth understanding of the actual manufacturing level of the equipment.

3. Rigorous review of quality inspection

Formal manufacturers will conduct strict quality inspections on their products, covering raw material inspections, inspections during parts processing, and comprehensive inspections before finished products leave the factory. Common inspection items include hardness testing, flaw detection, dynamic balancing testing, etc. When purchasing equipment, be sure to ask the supplier to provide a detailed quality inspection report to ensure that the equipment meets relevant quality standards and industry specifications. At the same time, you can also learn about the manufacturer's quality certification, such as whether it has passed the ISO9001 quality management system certification, which is also an important reference for measuring the quality of the manufacturer's products.

Jaw Crusher

C. Carefully consider the brand and after-sales service

1. In-depth research on brand reputation

Brand is an intuitive reflection of the comprehensive strength of the enterprise and the quality of its products. When choosing a jaw crusher, you should give priority to brands with high popularity and good reputation in the market. Well-known brands usually have many years of production experience and deep technical accumulation, and their products have high guarantees in terms of performance, quality and stability. Take the jaw crusher under Falsmith as an example. With its advanced technology and reliable quality, it has been widely used and recognized worldwide. You can learn about the market reputation and user feedback of different brands through various channels such as industry forums, customer reviews, and consulting industry experts, so as to make a more wise choice.

2. Learn more about after-sales service

Perfect after-sales service is an important guarantee for the normal operation of equipment. When purchasing a crusher, you should learn more about the supplier's after-sales service content and response time. Including equipment installation and commissioning, operation training, regular maintenance, parts supply, and fault repair. A good supplier should be able to provide timely technical support and door-to-door service to ensure that problems with the equipment can be quickly resolved, minimize downtime, and reduce production losses. At the same time, we should pay attention to the inventory of parts of suppliers to ensure that they can be supplied in time when parts need to be replaced, so as to avoid affecting the normal operation of equipment due to shortage of parts.

D. Rationally compare prices and cost-effectiveness

Jaw Crusher

1. Objectively look at price factors

Price is an unavoidable factor when purchasing equipment, but the purchase decision should never be determined solely by the price. The prices of jaw crushers of different brands and models vary greatly, and their prices are affected by many factors such as equipment quality, performance, configuration, and market supply and demand. When comparing prices, they should be based on the same specifications and performance, avoiding the pursuit of low prices while ignoring the quality and after-sales service of the equipment. Some low-priced equipment may save procurement costs in the short term, but in the long-term use process, it may increase the operating costs of the enterprise due to quality problems and frequent maintenance.

2. Scientifically analyze cost-effectiveness

Cost-effectiveness is an important indicator obtained after comprehensive consideration of factors such as equipment price, quality, performance and after-sales service. When purchasing a jaw crusher, a comprehensive cost-effectiveness analysis should be conducted on equipment of different brands and models. For example, a crusher with a slightly higher price but reliable quality, excellent performance and perfect after-sales service may save more costs and create higher economic benefits for the company during long-term use due to its high efficiency, low failure rate and long service life. Therefore, when purchasing equipment, it is necessary to choose the most cost-effective product from a long-term perspective.

E. Conduct field investigation and trial machine

Jaw Crusher

1. Field investigation of manufacturers

Before making a purchase decision, if conditions permit, it is best to conduct a field investigation of the manufacturer. Through field investigation, you can intuitively understand the manufacturer's production scale, technical strength, production equipment and quality control system. At the same time, you can also communicate face-to-face with the manufacturer's technicians and sales staff to gain an in-depth understanding of the performance characteristics, operation methods and maintenance points of the equipment. During the inspection process, pay attention to whether the manufacturer's production environment is clean and orderly, and whether the production process is standardized, which can also reflect the manufacturer's management level and product quality from the side.

2. Conduct on-site trial machine carefully

On-site trial machine is the most direct way to test the performance of the crusher. During the trial run, you can use your own materials for crushing and observe the operating conditions of the equipment, including whether the feeding is smooth, the crushing efficiency, whether the finished product particle size meets the requirements, whether the equipment is stable, and whether there is abnormal noise and vibration. The trial run can also allow operators to personally experience the convenience and safety of the equipment. If conditions permit, it is best to conduct a long trial run to fully evaluate the performance and reliability of the equipment.

PS: Purchasing a jaw crusher requires comprehensive consideration of multiple factors, from accurately positioning your own needs, comprehensively evaluating the quality of the equipment, carefully considering the brand and after-sales service, rationally comparing prices and cost-effectiveness, to actually conducting field inspections and trial runs. Each link is crucial. Only by mastering these purchasing skills can you select a high-quality jaw crusher that meets the needs of your own company, provide strong guarantees for the company's production operations, and create greater economic benefits.

Save Time! Get A Detailed Quotation Quickly.