Preface: With the acceleration of urbanization and the growth of population, the amount of garbage generated is increasing day by day. Garbage disposal has become one of the important environmental problems facing modern society. Among the many links of garbage disposal, crushing equipment plays a key role. It can crush various forms of garbage to make it easier for subsequent transportation, landfill, incineration or recycling. This article will introduce in detail the crushing equipment commonly used in garbage disposal.

1.Jaw crusher

Jaw crusher

The jaw crusher is an ancient and widely used crushing equipment. Its working principle is based on the relative movement between the movable jaw and the fixed jaw. The motor drives the eccentric shaft to rotate, so that the movable jaw swings periodically. When the movable jaw approaches the fixed jaw, the material is squeezed, split and crushed; when the movable jaw leaves the fixed jaw, the crushed material is discharged under the action of gravity.

The advantages of the jaw crusher are obvious. It has the characteristics of simple structure, durability and easy maintenance. Its crushing ratio is large and can handle garbage of various hardness, from ordinary household garbage to high-hardness construction garbage. When dealing with concrete blocks, bricks, etc. in construction waste, the jaw crusher can crush them into smaller particles for subsequent recycling and reuse, such as making recycled aggregate for road base paving or concrete production.

2. Hammer crusher

Hammer crusher

The hammer crusher mainly relies on the high-speed rotating hammer to impact and crush the material. The motor drives the rotor to rotate at high speed, and the hammer opens under the action of centrifugal force. When the garbage enters the crushing chamber, it is violently impacted by the high-speed rotating hammer, collides with the crushing plate, screen bars and other components, and is broken into small pieces.

The hammer crusher has high crushing efficiency and can crush the material to a smaller particle size at one time. It is suitable for handling more brittle garbage, such as waste wood, plastic, etc. When dealing with waste wood, the hammer crusher can quickly crush it into wood chips, which can be used to make fiberboard, biomass fuel, etc. Moreover, the operation of the hammer crusher is relatively simple, easy to realize automatic control, and can meet the needs of large-scale garbage disposal.

3. Shear crusher

The shear crusher uses the shearing action of the blade to crush the garbage. It usually consists of a fixed blade and a movable blade. The movable blade reciprocates under hydraulic or mechanical drive and cooperates with the fixed blade to shear and tear the garbage entering the crushing chamber.

This crusher has unique advantages in processing large and irregularly shaped garbage, such as waste furniture, large plastic containers, etc. When processing waste furniture, the shearing crusher can disassemble and crush it into suitable sizes for subsequent recycling. In addition, the shearing crusher has low noise and small dust pollution during operation, which meets environmental protection requirements and is increasingly widely used in urban garbage treatment.

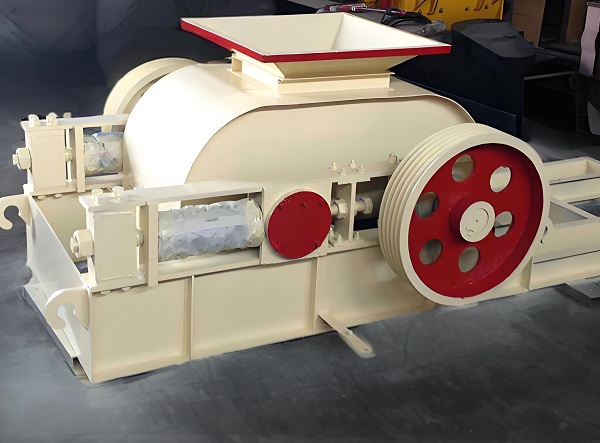

4. Roller crusher

Roller crusher

The roller crusher consists of two or more rollers rotating relative to each other. When the material enters the gap between the rollers, it is crushed by the squeezing and friction of the rollers. According to the surface shape and working mode of the roller, it can be divided into a smooth roller crusher and a toothed roller crusher.

The smooth roller crusher is suitable for processing garbage with lower hardness and less viscosity, such as organic matter in some domestic garbage. The toothed roller crusher is more suitable for processing garbage with higher hardness and impurities, such as small pieces of stone and metal in construction waste. The advantages of roller crusher are smooth crushing process, low energy consumption, and the ability to adjust the gap between rollers as needed to control the particle size of the crushed material.

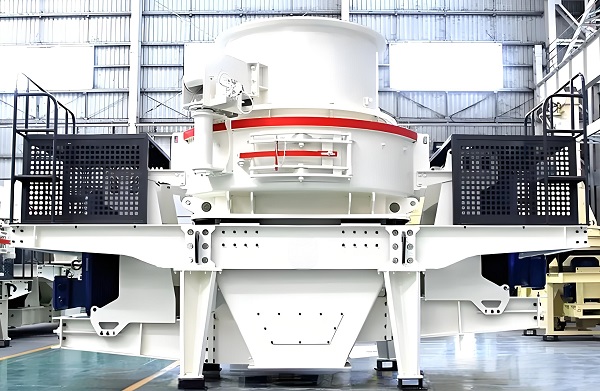

5. Impact crusher

Impact crusher

The impact crusher uses a high-speed rotating impeller to accelerate the material and eject it, so that it collides with the impact plate or other materials inside the crushing chamber and breaks it. Its crushing process has a strong impact effect, which can cause the material to be crushed by a huge impact force in an instant.

The impact crusher is particularly suitable for processing hard materials in construction waste, such as quartz stone, granite, etc. After the construction waste is processed by the impact crusher, the particle shape is regular and the particle size is uniform, which can be used as high-quality recycled aggregate for construction projects. In addition, the impact crusher has a large production capacity and can meet the needs of large-scale construction waste treatment.

PS: There are many types of crushing equipment in garbage treatment, and each equipment has its unique working principle, scope of application and advantages. In actual garbage treatment projects, it is necessary to reasonably select and configure crushing equipment according to factors such as the type, nature, treatment scale and requirements of subsequent treatment processes of the garbage, so as to achieve efficient, environmentally friendly and economical garbage treatment. With the continuous advancement of technology, crushing equipment is also developing towards intelligence, efficiency, energy saving and environmental protection, providing strong support for the sustainable development of the waste disposal industry.

Save Time! Get A Detailed Quotation Quickly.