In fine and medium crushing operations in industries such as mining, infrastructure construction, and building materials, the spring cone crusher, with decades of technological accumulation, has become a core piece of equipment that combines stability and practicality. As a classic model of cone crusher, it overcomes the pain points of traditional equipment—low efficiency and susceptibility to failure—by offering a mature structural design and highly efficient crushing performance. With the increasing demands for durability, cost control, and adaptability of crushing equipment in industrial production, the advantages of the spring cone crusher are becoming increasingly prominent. This article will deeply analyze its core advantages from the dimensions of structure, efficiency, operation and maintenance, and application, providing practical references for industry users to optimize selection, reduce costs, and increase efficiency, helping related fields achieve large-scale and efficient production.

1. Classic Structural Design, Stable Operation and Outstanding Durability

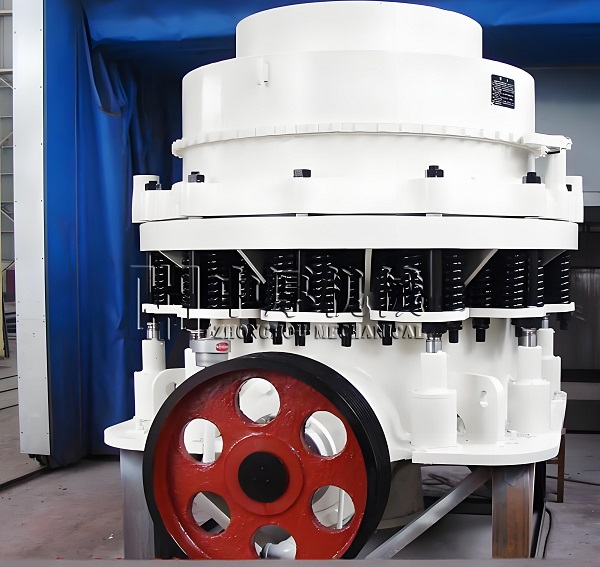

As a classic model of cone crusher, the core advantage of the spring cone crusher stems from its structural design, which has been proven through long-term practice, exhibiting particularly outstanding performance in stability and service life. This equipment features a rigid, integrated frame, formed through a single casting process. The frame boasts high strength and minimal deformation, effectively withstanding the immense impact and extrusion forces generated during crushing. Compared to spliced frames, its vibration resistance is improved by over 30%, laying a solid foundation for long-term stable operation.

The core working components, the moving and fixed cones, are made of high-manganese steel or high-chromium alloy steel, undergoing water toughening and quenching processes to achieve a surface hardness of HRC55-60, demonstrating excellent wear resistance. For crushing high-hardness materials (such as basalt and quartzite), its liner service life is extended by 2-3 times compared to ordinary crushers, reducing downtime caused by frequent liner replacements. Furthermore, key components such as the eccentric shaft and drive shaft are forged, resulting in high precision and toughness, enabling continuous operation under high load conditions. The equipment's annual uptime consistently exceeds 90%, far surpassing the industry average.

The spring safety system is a signature design feature of this model. High-strength springs provide elastic support. When uncrushable materials such as iron blocks enter the crushing chamber, the springs deform elastically, pushing the fixed cone backward and automatically widening the discharge opening to allow the foreign objects to be discharged smoothly. After the foreign objects are removed, the spring's restoring force allows the fixed cone to quickly return to its working position, resuming production without manual intervention. This effectively avoids serious malfunctions such as gear damage and shaft breakage caused by overload, significantly reducing equipment maintenance costs and downtime losses.

2. Superior Crushing Efficiency and Product Quality, Adapting to Diverse Needs

With its scientific crushing chamber design and layered crushing principle, the spring cone crusher offers dual advantages in crushing efficiency and product quality, making it the preferred equipment for medium and fine crushing operations. The crushing chamber is available in three types: standard, medium, and short-head, allowing for flexible switching based on material properties and output requirements. The standard chamber is suitable for medium crushing operations, with a crushing ratio of approximately 4-6, capable of handling larger particle sizes. The short-head chamber is suitable for fine crushing operations, with a crushing ratio of up to 8-10, producing fine materials with a particle size of less than 10mm, meeting the processing needs of various industries.

Regarding crushing efficiency, the spring cone crusher offers a wide range of processing capacities, from 10t/h for small models to 1500t/h for large models, adaptable to large-scale production in everything from small and medium-sized quarries to large mines. Taking the PYB-1750 spring cone crusher as an example, when processing medium-hard materials such as granite, its hourly processing capacity can reach 300-500t, representing a more than 40% increase in processing efficiency compared to a hammer crusher of the same specifications. It also boasts a larger crushing ratio, reducing crushing steps and shortening the production process.

In terms of product quality, the application of the layered crushing principle allows materials to undergo multi-layer compression and grinding within the crushing chamber, resulting in more thorough particle crushing. The content of needle-like and flaky particles is controlled below 8%, producing a regular cubic particle shape with continuous and uniform gradation. In concrete aggregate production, this high-quality aggregate can increase the compressive strength of concrete by 15-20% and significantly improve workability, meeting the stringent requirements for aggregate quality in high-grade buildings, high-speed railways, bridges, and other projects. Furthermore, the discharge port can be precisely adjusted by adjusting the spring compression, with an adjustment range of 5-50mm, flexibly adapting to different discharge particle size requirements and improving production flexibility.

3. Convenient Operation and Maintenance, Low Overall Operating Costs

The spring cone crusher is designed with practicality in mind in terms of operation and maintenance, significantly reducing labor and time costs. The equipment uses manual or hydraulically assisted adjustment of the discharge port, making operation simple and convenient. No complex professional skills are required; ordinary operators can learn to operate it after a short training period. Meanwhile, the equipment's lubrication system adopts a centralized oil supply design, equipped with a complete set of devices including an oil tank, oil pump, and cooler. It automatically provides lubrication to key components such as bearings and gears, reducing wear. The lubrication system also features oil level and temperature monitoring devices for real-time monitoring of operating status and timely detection of abnormalities.

In terms of maintenance, the equipment has a rational structural layout, and key components such as liners and crushing walls adopt a modular design, making disassembly and replacement convenient. Simple maintenance can be performed by a single person. The liners are bolted, reducing replacement time by more than 50% compared to traditional models, significantly reducing maintenance downtime. Furthermore, the spring cone crusher has fewer types of vulnerable parts, high versatility, ample market supply, and low procurement costs. Some vulnerable parts can also be repaired and reused, further reducing consumable expenses.

Regarding energy consumption control, the spring cone crusher has a rationally matched motor power and high transmission efficiency, with a unit energy consumption of only 1.2-2.5 kWh/t, which is about 30% more energy-efficient than traditional jaw crushers. Taking a production line with an annual processing capacity of 1 million tons as an example, it can save hundreds of thousands of yuan in electricity costs annually, demonstrating significant long-term energy-saving advantages. Simultaneously, the equipment operates at a noise level below 85dB, employing a sealed crushing chamber design with minimal dust leakage. It can meet environmental protection requirements with a simple dust removal device, eliminating the need for additional high-cost environmental protection equipment.

4. Wide Range of Applications and Strong Adaptability

The spring cone crusher, with its stable performance, high crushing capacity, and flexible adaptability, is widely used in multiple industries, becoming a highly versatile crushing equipment. In the mining industry, it can be used for medium and fine crushing of metallic ores such as iron ore, copper ore, and lead-zinc ore, and is also suitable for processing non-metallic ores such as limestone, granite, and marble. It is particularly suitable for processing high-hardness, highly abrasive materials, achieving industry-leading crushing efficiency and product quality.

In the construction and building materials industry, the spring cone crusher is a core piece of equipment for concrete aggregate production, demonstrating excellent performance in both natural stone processing and the production of recycled construction waste aggregates. In construction waste treatment projects, it can crush waste concrete blocks, bricks, and other materials into recycled aggregates that meet standards, with low needle-like and flaky content and reasonable gradation. These aggregates can be directly used for concrete mixing and road base paving, achieving resource recycling.

In the infrastructure engineering field, projects such as highways, railways, airports, and ports have large demands and high quality requirements for aggregates. Spring cone crushers, with their high processing capacity and stable product quality, have become the main equipment for infrastructure aggregate production. For example, in highway construction, a large amount of uniformly sized, high-strength crushed stone is needed for roadbed and pavement paving. Spring cone crushers can precisely produce aggregates of different specifications by adjusting the cavity shape and discharge port to meet the needs of engineering construction. In addition, this equipment can also be used for raw material crushing in industries such as metallurgy and chemicals, such as blast furnace slag crushing in the metallurgical industry and gypsum crushing in the chemical industry, adapting to the crushing needs of different materials.

5. Mature and Reliable Technology, High Market Acceptance After decades of technological iteration and market verification, the spring cone crusher has achieved high technological maturity and stable and reliable performance, gaining widespread recognition in both domestic and international markets. The core technology of this model has been standardized, with mature production processes and a comprehensive quality control system. Equipment from different manufacturers maintains consistency in core performance, resulting in low selection and replacement costs for users.

Compared to newer hydraulic cone crushers, spring cone crushers have a simpler structure, lower technical barriers to entry, more readily available maintenance technology, and ample spare parts supply, making them particularly suitable for small and medium-sized enterprises and users with relatively limited technical expertise. Furthermore, their price is relatively affordable, with lower initial investment costs than hydraulic cone crushers of the same specifications, offering high cost-effectiveness. They can achieve high-efficiency production with lower investment, making them suitable for users with limited budgets but certain requirements for crushing efficiency and quality.

In market applications, spring cone crushers have received positive user feedback. Numerous long-term usage cases in mining and building materials companies have proven their stable performance and excellent cost-effectiveness. For example, a large limestone quarry using a PYB-2200 spring cone crusher has operated continuously for 5 years without major malfunctions, with a liner replacement cycle of 8 months, a stable throughput of 800 t/h, and a product qualification rate consistently above 95%, creating significant economic benefits for the company.

Spring cone crushers hold a significant position in the crushing equipment market due to their classic and reliable structural design, superior crushing performance in both efficiency and quality, convenient and economical operation and maintenance, and wide adaptability. Their integrated frame and spring safety system ensure operational stability, the layered crushing principle optimizes product quality, and their low energy consumption and easy maintenance design reduce overall costs, making them suitable for diverse crushing needs across multiple industries. With its mature technology and high cost-effectiveness, it has become the preferred equipment for small and medium-sized enterprises and large projects. In the future, with process upgrades and increasing energy-saving requirements, spring cone crushers will continue to provide solid support for crushing operations in various industries with their stable and efficient performance.

Save Time! Get A Detailed Quotation Quickly.