Shredders play a vital role in modern industrial production and resource recycling. Their efficient and stable material shredding capabilities directly impact production efficiency and economic returns. Among numerous brands, Zhongcheng shredders stand out for their superior performance, reliable quality, and comprehensive service, becoming the preferred choice for many businesses. The following will provide an in-depth analysis of the reasons for choosing Zhongcheng shredders from multiple perspectives.

Superior Performance

1. Powerful Shredding Capacity

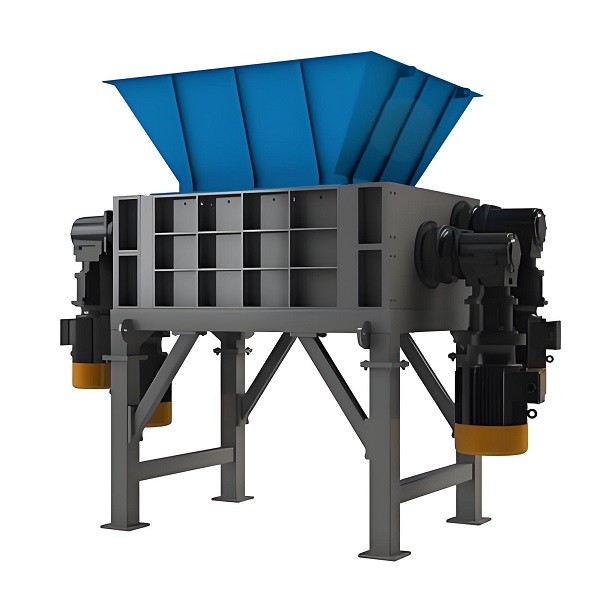

Zhongcheng shredders feature advanced design concepts and are equipped with a variety of blade shaft and tool combinations tailored to the characteristics of different materials. For example, a twin-shaft shredder utilizes dual independent drive technology. During operation, the two blade shafts rotate in opposite directions, generating powerful shearing and tearing forces that can easily handle a wide range of materials. Whether scrap metal, plastic, wood, rubber tires, or construction waste, they can all be efficiently shredded. For thick, hard materials such as scrap metal sheets and large plastic pipes, Zhongcheng shredders optimize their blade shaft structure to increase torque output, ensuring high-torque shredding even at low speeds. This avoids equipment stalls and downtime caused by difficult-to-crush materials, significantly improving production efficiency.

2. Wide Material Compatibility

Industrial production and resource recycling processes utilize a wide variety of materials with diverse compositions. Zhongcheng shredders take this into account and offer a wide range of material compatibility. Their blades are made of special alloy steel and undergo a specialized heat treatment process, resulting in exceptional hardness and wear resistance. They effectively shred hard materials while maintaining excellent cutting performance even with tough, sticky materials. When processing mixed materials in household waste, Zhongcheng shredders can simultaneously shred diverse materials, including paper, plastic film, fabric, and wooden furniture fragments, meeting the pre-processing requirements for subsequent waste sorting and resource recovery. Zhongcheng Environmental Protection has developed a powerful shredder specifically designed to specifically shred and decompose stale waste, a material with complex composition, prone to entanglement, and high water and mud content. This shredder is capable of specifically crushing and disintegrating large pieces of waste and entangled materials, perfectly matching the feed requirements of subsequent sorting equipment and demonstrating excellent material adaptability.

3. Precise Output Control

Different production processes require varying particle size after shredding. Zhongcheng's shredder design takes this into account. By flexibly adjusting the blade gap, blade shaft speed, and equipping it with screens of varying specifications, precise control of the output particle size is achieved. Users can easily shred materials to the desired size, from coarse to fine, based on their specific production needs. In the plastics recycling industry, if subsequent processing requires plastic to be crushed into uniformly small particles for melt regranulation, Zhongcheng's shredder can precisely adjust and pulverize plastic waste into consistent particles, providing high-quality raw materials for subsequent processing and improving product quality and production efficiency.

Reliable Product Quality

1. High-Quality Raw Material Selection

Product quality is fundamentally based on raw materials. During the production process, Zhongcheng shredders strictly control the procurement of raw materials, selecting high-quality steel and alloy materials for key components. The machine body is welded from high-strength steel plates and treated with a special process, resulting in excellent rigidity and stability. It can withstand long-term, high-intensity workloads and is resistant to deformation and cracking. The blade shaft is forged from high-quality alloy steel, precision machined, and heat-treated, resulting in exceptional strength and toughness, enabling stable operation even under immense torque. The cutters are made from a special wear-resistant alloy, far exceeding the hardness and wear resistance of ordinary steel, significantly extending the tool life and reducing maintenance costs.

2. Exquisite Manufacturing Process

Zhongcheng boasts a modern production facility and advanced processing equipment, demonstrating exceptional manufacturing craftsmanship. During the production process, we strictly adhere to international quality management system standards, ensuring meticulous polishing at every step. From component machining to complete machine assembly and commissioning, we strive for excellence. The blade shaft is machined to micron-level precision, ensuring concentricity and balance, minimizing vibration and noise during operation. The cutting tools are manufactured using advanced precision casting and heat treatment processes to ensure cutting edge sharpness and wear resistance, while also enhancing overall strength. After assembly, the entire machine undergoes rigorous no-load and load testing to ensure that all performance indicators meet design requirements before shipment, ensuring reliable and stable products for our customers.

3. Strict Quality Inspection System

To ensure that every Zhongcheng shredder meets high quality standards, the company has established a comprehensive and rigorous quality inspection system. From incoming raw material inspection to spot checks during component processing, and finally to comprehensive pre-shipment inspections, every step is meticulously scrutinized. Advanced testing equipment and professional personnel ensure precise testing of all performance indicators. For motor performance testing, a professional motor test bench is used to thoroughly examine the motor's power, speed, torque, and insulation properties to ensure stable and powerful operation. For operational stability testing, long-term load tests are conducted to simulate actual operating conditions, monitoring parameters such as vibration, noise, and temperature. This allows potential issues to be identified and addressed promptly, ensuring long-term stable operation at the customer's site.

Advanced Technological Innovation

1. Intelligent Control System

Zhongcheng shredders keep pace with the trend of industrial intelligence and are equipped with an advanced intelligent control system. This system, with a programmable logic controller (PLC) at its core, integrates multiple functions, including equipment operating status monitoring, fault diagnosis, and automatic control. The operator can easily start, stop, and control forward and reverse rotation through the human-machine interface (HMI), while also monitoring real-time operating parameters such as motor current, blade shaft speed, and material temperature. In the event of an abnormality such as an overload or material blockage, the control system quickly responds by automatically activating overload protection and reverse rotation to prevent damage. Fault information is also displayed on the HMI, helping maintenance personnel quickly locate the fault and conduct repairs. The application of an intelligent control system not only improves the convenience of equipment operation but also significantly enhances operational safety and stability, reducing manual operation costs and labor intensity.

2. Energy-Saving Technologies

With energy costs rising, energy-saving performance has become a key concern for manufacturers. Zhongcheng shredders are designed and manufactured with energy-saving considerations in mind, incorporating multiple energy-saving technologies. Optimizing the matching between the motor and reducer, and selecting high-efficiency, energy-saving motors, improves the motor's power conversion efficiency and reduces energy consumption. During operation, the intelligent control system automatically adjusts the motor speed and cutter shaft torque based on the material feed rate and crushing difficulty, avoiding high energy consumption when the equipment is lightly loaded or unloaded. Furthermore, the equipment's transmission system has been optimized, employing low-friction bearings and seals to reduce energy loss during mechanical transmission, further reducing equipment operating costs and providing strong support for the company's green and sustainable development.

3. Innovative Cutter Design

As the core component of a shredder, the quality of its cutter design directly impacts the equipment's crushing performance and service life. Zhongcheng continuously invests in cutter research and development, launching a series of innovative cutter designs. Special cutter shapes and arrangements, such as a spiral cutter arrangement, achieve efficient cutting during operation, improving material crushing efficiency while also ensuring more uniform force distribution and reducing wear. The hexagonal design of the cutter bore and spindle surface effectively strengthens the connection between the cutter and spindle, ensuring that the cutter will not loosen or shift under high torque conditions, ensuring stable operation. In addition, we develop cutting tools in a variety of materials and structures to address different material characteristics, such as carbide cutting tools for hard materials and high-toughness alloy cutting tools for tough materials, to meet users' diverse production needs.

Comprehensive After-Sales Service

1. Professional Technical Support Team

Zhongcheng boasts an experienced and highly skilled professional technical support team, providing comprehensive technical support. From equipment selection and installation and commissioning to troubleshooting and technical consultation during operation, the technical support team is responsive and helpful. During the equipment selection phase, technicians will provide professional equipment selection recommendations based on the user's specific needs, such as material characteristics, production scale, and site conditions, ensuring that the user selects the shredder model that best suits their production needs. During the equipment installation and commissioning process, technicians will visit the site to provide on-site guidance and commissioning, ensuring smooth operation. They will also provide on-site training for the user's operators to ensure they master equipment operation and routine maintenance skills.

2. Timely After-Sales Response Mechanism

Timely after-sales service is of paramount importance to our users. Zhongcheng has established a comprehensive after-sales response mechanism to ensure prompt response when users encounter equipment malfunctions. Users can report equipment issues through various channels, including the 400 customer service hotline and online customer service platform. Upon receiving feedback, after-sales staff will immediately record the issue and forward it to the relevant technician. The technician will contact the user within a specified timeframe to understand the details of the problem and develop a solution based on the issue. For simple issues, the technician will provide on-site repair guidance via phone or video. For complex issues, the technician will arrange an on-site visit as quickly as possible, bringing the necessary repair tools and spare parts to the user's site for repair, minimizing equipment downtime and reducing user losses.

3. Adequate Spare Parts Supply

To ensure timely equipment maintenance, Zhongcheng has established a sufficient spare parts warehouse, stocking a large number of commonly used spare parts and consumable parts. Whether it's cutting tools, bearings, seals, or key components like motors and reducers, replacement needs can be met at any time. The spare parts warehouse utilizes an information management system that monitors spare parts inventory, inbound and outbound records, and other data in real time to ensure that spare parts inventory is always maintained at an appropriate level. We have also established long-term partnerships with numerous high-quality suppliers to ensure the quality and stable supply of spare parts. When users require replacement parts, after-sales personnel can quickly check spare parts inventory and arrange for timely delivery, ensuring that users receive the required parts as quickly as possible and their equipment is restored to normal operation.

Strong Market Reputation and Extensive Application Cases

1. Market Reputation and Praise

Through long-term market development, Zhongcheng shredders have earned widespread recognition and praise from users for their superior performance, reliable quality, and comprehensive service. They have established a strong brand image within the industry and enjoy excellent user reputation. Numerous companies using Zhongcheng shredders report that the equipment offers stable operation, excellent shredding results, and low maintenance costs, resulting in significant economic benefits. Numerous positive reviews and recommendations for Zhongcheng shredders can be found on major industry forums, social media platforms, and customer review websites. These genuine user reviews serve as a powerful testament to the quality of Zhongcheng shredders and are attracting an increasing number of potential users to choose Zhongcheng products.

2. Extensive Application Cases

Zhongcheng shredders are widely used in a variety of industries, including industrial waste recycling, medical recycling, electronics manufacturing, pallet manufacturing, wood processing, household waste recycling, plastic recycling, tire recycling, and papermaking, accumulating a wealth of application cases. In the plastics recycling industry, a large plastics recycling company uses a Zhongcheng dual-shaft shredder to shred waste plastics. The equipment operates stably, with high shredding efficiency and uniform output particle size, meeting the company's raw material needs for subsequent plastic granulation production, significantly improving production efficiency and economic benefits. In the field of household waste disposal, a city's waste treatment plant has introduced a Zhongcheng shredder for pre-processing and shredding mixed household waste. This effectively solves the problem of material shredding before sorting, improves waste sorting efficiency and resource utilization, and provides strong support for municipal waste management. These successful application cases fully demonstrate the Zhongcheng shredder's excellent adaptability and superior performance across diverse industries and operating conditions, providing valuable application references for potential users.

Zhongcheng shredders, with their superior performance, reliable product quality, advanced technological innovations, comprehensive after-sales service, excellent market reputation, and extensive application cases, have become the preferred choice for many companies in the material shredding field. Choosing a Zhongcheng shredder is not only about choosing a highly efficient piece of production equipment, but also about choosing a comprehensive solution that provides a solid foundation for the company's production and development, helping it stand out in the fierce market competition and achieve sustainable development.

Save Time! Get A Detailed Quotation Quickly.