Preface: In many links of industrial production, iron impurities in materials are often the "invisible killer" that affects product quality and the normal operation of production equipment. As a device specially used to remove ferromagnetic substances in materials, iron removers play an indispensable role in various industries. Understanding the concept, working principle and wide range of functions of iron removers is of great significance to ensure the smooth progress of production and improve product quality.

1.Concept and definition of iron removers

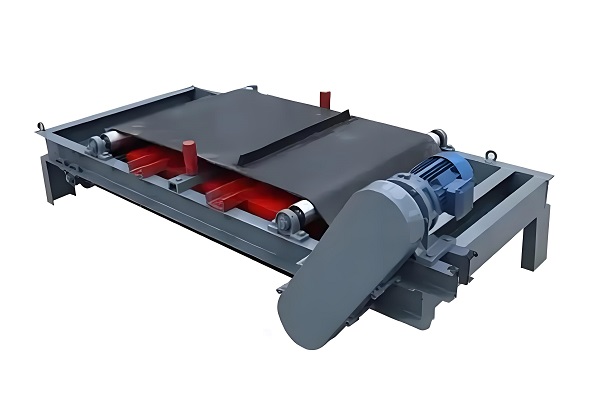

Iron remover

Iron removers are devices that use the principle of magnetic field to remove ferromagnetic impurities from powdered, granular or block materials. These ferromagnetic impurities may come from the raw materials themselves, equipment wear during the production process, or foreign matter mixed in during transportation and storage. Iron removers can effectively separate these impurities, ensure the purity of the materials, and meet the requirements of production processes and product quality.

2. Working principle of iron removers

Iron remover

Electromagnetic induction principle: Most iron removers work based on the principle of electromagnetic induction. When materials containing ferromagnetic impurities pass through the magnetic field area generated by the iron remover, the ferromagnetic substances will be strongly attracted by the magnetic field. Taking the electromagnetic iron remover as an example, the internal excitation coil generates a strong magnetic field after being energized, and the magnetic field strength can be controlled by adjusting the current. When the material is in the magnetic field, the ferromagnetic impurities are acted upon by the magnetic force, overcome their own gravity and the friction between the materials, and are adsorbed to the magnetic pole surface of the iron remover, thereby separating from the material.

Permanent magnet principle: The permanent magnetic iron remover works by using the constant magnetic field generated by the permanent magnet. Permanent magnets are made of special magnetic materials, such as neodymium iron boron, which have high magnetic energy product and coercive force and can maintain a stable magnetic field for a long time. When the material passes through the magnetic field range of the permanent magnetic iron remover, the ferromagnetic impurities are adsorbed by the permanent magnet to achieve the purpose of separation. The permanent magnetic iron remover does not require an external power supply and has the advantages of simple structure and low operating cost.

3. Common types of iron removers

Iron remover

Suspended iron remover: This is a more common type of iron remover, usually installed above the belt conveyor. It is suspended in a suitable position by a hanger so that the material passes under its magnetic field during the belt conveying process. The suspended iron remover is suitable for removing iron impurities from powdery and granular materials. It is easy to install and does not take up too much space. According to the way the magnetic field is generated, it can be divided into suspended electromagnetic iron removers and suspended permanent magnetic iron removers.

Pipeline iron remover: It is mainly used in the iron removal scene of pipeline conveying materials. It is installed inside the material conveying pipeline. When the material flows in the pipeline, the ferromagnetic impurities are adsorbed on the inner wall of the pipeline or on the magnetic pole by the magnetic field of the iron remover. The pipeline iron remover can realize continuous iron removal of materials and is suitable for the iron removal of powdered or liquid materials with high material purity requirements in the food, chemical and other industries.

Self-unloading iron remover: It combines the automatic iron unloading function and can automatically remove iron impurities adsorbed on the surface of the magnetic pole without stopping the machine. It is usually equipped with an iron unloading belt or scraper device. When the adsorbed iron impurities reach a certain amount, the iron unloading device starts to transport the iron impurities to the designated location for collection. The self-unloading iron remover is suitable for the iron removal of materials with large processing volume and high iron impurity content, which greatly improves the iron removal efficiency and the degree of automation of the equipment.

4. Application fields of iron removers

Iron remover

Mining industry: During mining and mineral processing, ores often contain various ferromagnetic impurities. Iron removers are used to remove these impurities, which can not only protect crushers, ball mills and other equipment from damage by iron impurities, extend the service life of the equipment, but also improve the grade and quality of the concentrate. For example, in iron ore beneficiation, the removal of impurities such as scrap steel mixed in by iron removers helps the subsequent magnetic separation, flotation and other processes to proceed smoothly.

Power industry: Coal is the main fuel for thermal power generation, and iron impurities such as iron nails and iron blocks are often mixed in coal. During coal transportation, the use of iron removers can effectively remove these impurities, prevent them from entering equipment such as coal mills and boilers, avoid equipment wear, blockage of pipelines and safety accidents, and ensure the stable operation of power production.

Food industry: Food production has extremely high requirements for hygiene and safety. Any mixing of iron impurities may affect the quality of food and the health of consumers. Iron removers are widely used in the processing of food raw materials, such as flour, grains, milk powder and other production lines, to ensure the purity of food and meet food safety standards.

Chemical industry: In chemical production, if powdered or granular raw materials and products contain iron impurities, it may affect the chemical reaction and lead to unstable product quality. Iron removers are used in the pretreatment of chemical raw materials and the post-treatment of products to remove iron impurities and ensure the smooth progress of chemical production and the reliability of product quality.

5. The role of iron removers

Iron remover

Protecting equipment: Iron impurities are extremely harmful to production equipment. If they enter crushers, pulverizers and other equipment, they may cause serious wear of the impeller, hammer head, liner and other parts of the equipment, and even cause equipment failure and shutdown. Iron removers can remove iron impurities in materials in advance, effectively reduce the degree of equipment wear, reduce the number of equipment maintenance and the cost of replacing parts, extend the service life of equipment, and ensure the continuity of production.

Improve product quality: In many industries, the purity of products directly affects their quality and performance. For example, in the production of electronic materials, even trace amounts of iron impurities may affect the performance of electronic components. Removing iron impurities from materials through iron removers can improve the purity and quality stability of products and enhance the competitiveness of products in the market.

Ensure production safety: In some flammable and explosive production environments, sparks generated by the friction between iron impurities and equipment parts may cause fires or explosions. Iron removers can eliminate this safety hazard, ensure the safety of the production environment, and protect personnel and property.

PS: As an important industrial equipment, iron removers play a key role in many industries with their unique magnetic field separation principle and diverse types. From protecting production equipment, improving product quality to ensuring production safety, the application of iron removers provides strong support for the efficient, stable and safe operation of industrial production. With the continuous development of industrial technology, the performance and functions of iron removers are also being continuously optimized and expanded. In the future, they will be widely used in more fields and make greater contributions to the high-quality development of various industries. When selecting and using iron removers, enterprises should reasonably select and configure them according to their own production needs, material characteristics and other factors to give full play to the maximum efficiency of iron removers. At the same time, pay attention to the technological innovation and development trend of iron removers, and continuously improve the level of iron removal technology to adapt to increasingly stringent production requirements and market competition.

Save Time! Get A Detailed Quotation Quickly.