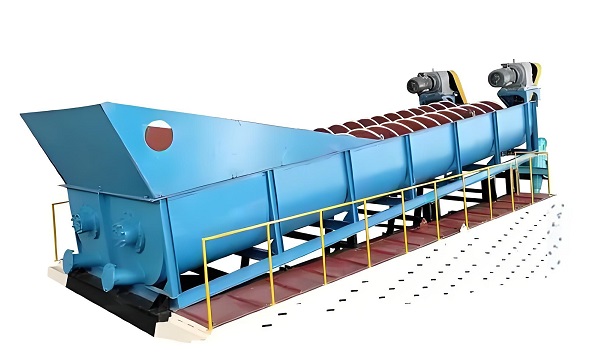

Preface: In many fields such as sand and gravel production and construction engineering, spiral sand washing machine, as an efficient and indispensable sand washing equipment, is playing a key role. It can accurately remove impurities such as soil and stone powder in sand and gravel, significantly improve the quality and purity of sand and gravel, and fully meet the stringent requirements of various projects for high-quality sand and gravel aggregates. Next, we will analyze the spiral sand washing machine in detail from multiple dimensions.

Spiral Sand Washer

A. Structural composition

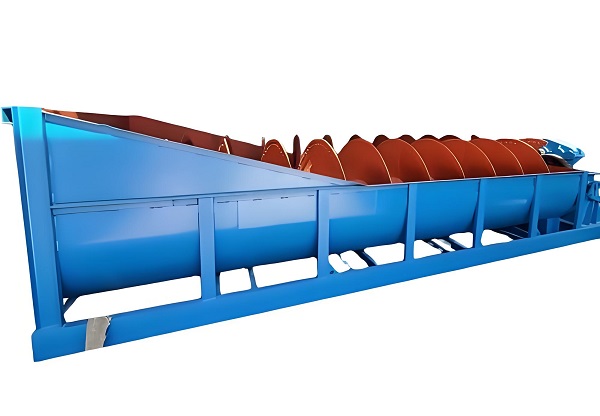

1. Spiral device: As the core component of the spiral sand washing machine, it consists of a spiral shaft, spiral blades and a transmission device. The spiral shaft is usually carefully made of high-quality steel, with sufficient strength and rigidity to ensure that it will not deform during long-term high-intensity operation. The spiral blades are designed into different shapes and sizes according to different sand washing needs, and their surfaces are generally treated with special processes to effectively improve wear resistance. The transmission device is responsible for accurately transmitting power to the spiral shaft, so that it can rotate stably and efficiently.

2. Washing trough: As a key container for holding sand and gravel and water for cleaning operations, it is usually welded with steel plates and has good sealing and corrosion resistance. The shape and size of the washing tank depend on the model and production capacity of the equipment. It is generally U-shaped or V-shaped. This design facilitates the smooth flow and full cleaning of sand and gravel.

3. Transmission system: covers important components such as motors, reducers, and couplings. The motor provides strong power as a power source. The high-speed rotation of the motor is accurately reduced to an appropriate speed through the reducer, and then the power is smoothly transmitted to the spiral shaft with the help of the coupling, thereby achieving stable rotation of the spiral blade. Whether the design of the transmission system is reasonable is directly related to the operating stability and energy consumption of the equipment.

4. Support device: It is composed of brackets, bearing seats and other components. It is mainly used to firmly support the spiral device and washing tank to ensure that the equipment remains stable during operation. The bracket generally adopts a sturdy steel structure with sufficient strength and stability to withstand the weight of the equipment and the impact force generated during operation. The bearing seat is installed on the bracket to support the spiral shaft to ensure that it can rotate flexibly and freely.

Spiral Sand Washer

B. Performance characteristics

1. Excellent sand washing effect: It can efficiently remove impurities such as mud and stone powder in sand and gravel, so that the surface of the sand and gravel after cleaning is clean and free of impurities, which greatly improves the quality and purity of sand and gravel. The mud content of sand and gravel after cleaning by the spiral sand washing machine can be strictly controlled below 1%, which fully meets the requirements of various high-standard projects for sand and gravel aggregates.

2. Efficient production capacity: The spiral blades are used to continuously convey sand and gravel, which realizes continuous production and greatly improves production efficiency. Compared with traditional sand washing equipment, the production capacity of the spiral sand washing machine can be increased by more than 30%, which can fully meet the needs of large-scale sand and gravel production.

3. Low energy consumption level: Thanks to the reasonable structural design and efficient transmission system, while ensuring excellent sand washing effect and high production efficiency, the energy consumption is significantly reduced. Compared with similar sand washing equipment, the spiral sand washing machine can save 20% - 30% energy, effectively reducing production costs.

4. Long service life: The main components such as spiral shaft, spiral blades, washing tank, etc. are made of high-quality materials and are processed by special processes, with good wear resistance and corrosion resistance. At the same time, the equipment has a reasonable structural design and stable operation, which greatly reduces the wear and failure rate of components and effectively extends the service life of the equipment. Under normal circumstances, the service life of the spiral sand washing machine can reach 8-10 years.

5. Simple operation and maintenance: The operation interface of the equipment is simple and clear, and the operator can master the operation method after simple training. In terms of maintenance, the design of each component fully considers the convenience of disassembly and installation, and daily maintenance and maintenance work is easy and convenient. At the same time, the low failure rate of the equipment also greatly reduces the maintenance time and maintenance cost.

Spiral Sand Washer

C. Operation precautions

Comprehensive inspection before starting: Before starting, the operator must conduct a comprehensive inspection of the equipment, including whether the connection of each component is firm, whether the transmission system is normal, whether the lubrication system is sufficient, whether there is debris in the washing tank, etc. Only when the equipment is in good condition can it be started and operated.

Reasonably adjust the operating parameters: According to different types of sand and gravel, particle size and mud content, reasonably adjust the equipment's speed, water intake and feed amount and other parameters to ensure the best sand washing effect and production efficiency. When adjusting the parameters, it is necessary to proceed step by step to avoid too large a one-time adjustment, so as not to affect the normal operation of the equipment.

Closely observe the operating status: During the operation of the equipment, the operator needs to closely observe the operating status of the equipment at all times, including whether the rotation of the spiral blade is stable, whether the sand and gravel are conveyed smoothly, whether there is abnormal noise and vibration, etc. Once an abnormal situation is found, the machine should be stopped for inspection immediately, and the operation should be continued after the fault is eliminated.

Regular maintenance: Regularly carry out comprehensive maintenance of the equipment, including cleaning the equipment, checking the wear of each component, timely replacing wearing parts, adding lubricating oil, etc. Regular maintenance can effectively extend the service life of the equipment, ensure the normal operation of the equipment, and further improve production efficiency.

Spiral Sand Washer

Strictly abide by the safety operating regulations: When operating the equipment, the operator must strictly abide by the safety operating procedures and wear personal protective equipment such as safety helmets and protective gloves. During the operation of the equipment, it is strictly forbidden to put your hands or other objects into the washing tank to avoid safety accidents.

PS: As an efficient, energy-saving and environmentally friendly sand washing equipment, the spiral sand washing machine has excellent working performance and a wide range of applications. With the continuous development of the construction industry, sand and gravel production industry, etc., the demand for high-quality sand and gravel aggregates is increasing day by day, and the market prospects of spiral sand washing machines will become more and more broad. When using a spiral sand washing machine, users should accurately select the appropriate model and specifications according to actual needs, and strictly operate and maintain it in accordance with the operating precautions to give full play to the performance advantages of the equipment and maximize production efficiency and economic benefits.

Save Time! Get A Detailed Quotation Quickly.