Preface: Spiral sand washing machine is a kind of efficient sand washing equipment, which is mainly divided into single spiral and double spiral. It mainly stirs the sand and gravel through the spiral device in the equipment to achieve the cleaning and screening effect of the sand and gravel. Spiral sand washing machine has the characteristics of low power consumption, high cleaning degree and good sealing structure. It is widely used in washing, grading and impurity removal in highway, hydropower, construction and other industries. It is suitable for washing fine and coarse grained materials. It is an efficient and energy-saving crushing sand making equipment.

A. Working principle of spiral sand washing machine

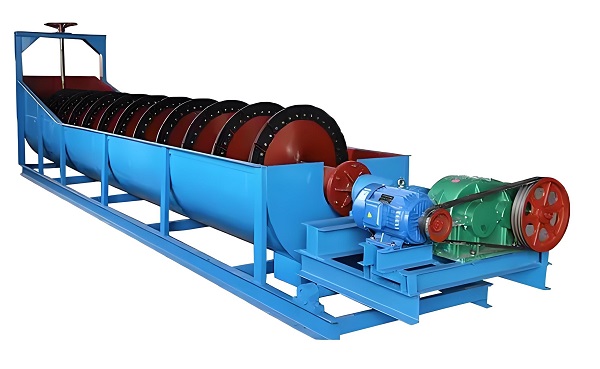

Spiral Sand Washing Machine

The operating mechanism of spiral sand washing machine revolves around the rotation of spiral blades to achieve an efficient sand washing process. After the equipment is started, the sand and gravel to be processed enter the washing tank in an orderly manner through the feed port. At the same time, water is continuously injected from the water inlet at the bottom of the washing tank, quickly forming an upward surging water flow. Driven by the strong motor, the spiral blades continue to rotate at a precise and stable speed. Under the powerful push of the blades, the sand and gravel rotate along the trajectory of the blades in the washing tank, while fully blending with the water and rolling violently. In this dynamic process, impurities such as soil and stone powder tightly attached to the surface of sand and gravel are strongly washed and gradually peeled off by the water flow. Since the density of these impurities is relatively small, they will be discharged smoothly from the overflow port along the direction of the water flow. The clean sand and gravel that have been fully washed are gradually lifted and transported to the discharge port under the continuous action of the spiral blades. At this point, the complete sand washing process is completed. This unique working mode not only ensures that the sand and gravel have sufficient time to fully contact with water in the washing tank and achieve deep cleaning, effectively ensuring the sand washing effect, but also the continuous conveying characteristics of the spiral blades enable the equipment to achieve uninterrupted continuous operation, greatly improving production efficiency.

B. The role of spiral sand washing machine

Spiral Sand Washing Machine

1. Improve the quality of sand and gravel

In the field of sand and gravel production and construction engineering, thoroughly removing impurities such as soil and stone powder in sand and gravel is a key link to ensure product quality and engineering safety. With its excellent cleaning ability, the spiral sand washing machine can effectively control the mud content of sand and gravel to less than 1%. After being cleaned, the surface of the sand and gravel is as clean as new, without any impurities remaining, which fundamentally greatly improves the quality and purity of the sand and gravel. As building aggregates, high-quality sand and gravel play an indispensable role in the preparation of concrete. It can significantly enhance the strength, durability and stability of concrete, and provide solid guarantees for the high-quality construction of construction projects. Taking large and complex projects such as high-rise buildings and bridges as an example, the use of sand and gravel carefully cleaned by spiral sand washing machines can effectively ensure the firmness and stability of the project structure, greatly extend the service life of the building, and withstand various natural environments and tests during use.

2. Meet the needs of different industries

The application range of spiral sand washing machines is extremely wide. In addition to playing a key role in the construction industry, it also shows important value in many other industries. In the glass manufacturing industry, the purity requirements for quartz sand are extremely high. The spiral sand washing machine can greatly improve its purity by finely cleaning the quartz sand, fully meeting the strict standards of glass manufacturing for high-purity raw materials, thereby effectively ensuring the transparency, strength and other key properties of glass products, and laying the foundation for the manufacture of high-quality glass products. In the construction of water conservancy and hydropower projects, the sand and gravel that meet the strict requirements of the project are widely used in the construction of important facilities such as dams and hydropower stations, providing a solid and reliable guarantee for the quality and safety of these large-scale water conservancy and hydropower projects that are related to the national economy and people's livelihood. In addition, in the casting, refractory materials, chemical and other industries, the spiral sand washing machine can also effectively clean various raw materials, significantly improve the quality of raw materials, and provide strong support for the production of high-quality products in these industries.

Spiral Sand Washing Machine

3. Improve production efficiency

From the perspective of sand and gravel production enterprises, the introduction of spiral sand washing machines is an important measure to enhance the comprehensive competitiveness and economic benefits of enterprises. By using spiral sand washing machines, enterprises can effectively improve product quality, accurately meet the market's urgent demand for high-quality sand and gravel, and then stand out in the fierce market competition, significantly improve the market competitiveness of products, and win more market share and economic benefits for enterprises. At the same time, the outstanding characteristics of spiral sand washing machines, such as continuous production, high efficiency and energy saving, and low maintenance costs, can effectively reduce the production costs of enterprises while ensuring the steady improvement of production efficiency, further optimize the production benefits of enterprises, and inject strong impetus into the sustainable development of enterprises.

PS: Spiral sand washing machine is an important sand and gravel processing equipment, and its main function is to clean and grade sand and gravel. Through the rotation of spiral blades, sand and gravel are fully stirred in the sand washing machine and contacted with water flow, effectively removing dirt, dust and other impurities on the surface of sand and gravel, and improving the cleanliness and quality of sand and gravel. At the same time, spiral sand washing machine can also grade sand and gravel according to different particle sizes to meet the requirements of sand and gravel specifications for different projects. This equipment is widely used in construction, highway, hydropower and other industries, and is an indispensable and important equipment in sand and gravel production lines.

Save Time! Get A Detailed Quotation Quickly.