PS: Crushing equipment is a mechanical equipment used to crush large pieces of material into smaller particles. It is widely used in many fields such as environmental protection, mining, smelting, building materials, roads, railways, water conservancy and chemical industry. Common crushing equipment mainly includes the following:

Jaw Crusher

1.Jaw crusher: commonly known as jaw crusher, it has the characteristics of large crushing ratio, uniform particle size, simple structure, reliable operation, easy maintenance and economical operating costs.

It is mainly used for coarse, medium and fine crushing of various materials with compressive strength not exceeding 320 MPa, such as granite, basalt, pebbles, limestone, etc.

It is widely used in many departments such as mining, smelting, building materials, roads, railways, water conservancy and chemical industry.

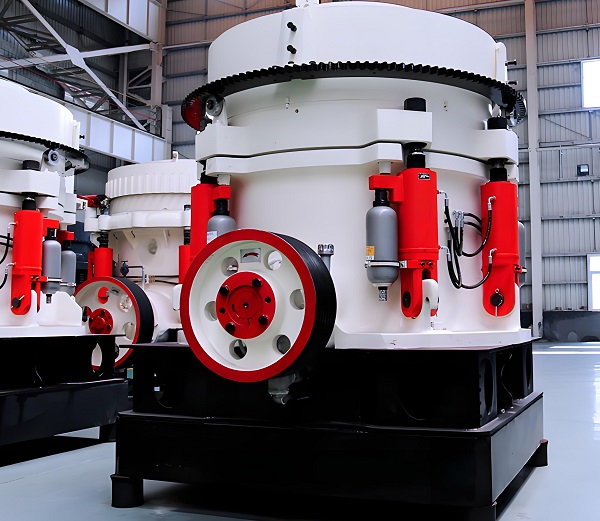

Cone Crusher

2. Cone crusher: suitable for harder materials, such as basalt, granite, etc. The working principle is that the material is between the inner and outer cones, the outer cone is fixed, and the inner cone swings eccentrically to crush or break the ore blocks sandwiched therein. A spring overload protection device is provided to allow foreign iron blocks to pass through the crushing chamber without harming the machine.

3. Gyratory crusher: suitable for crushing hard (compressive strength above 100MPa) and medium hardness (compressive strength around 100MPa) rock blocks.

Hammer Crusher

4. Hammer crusher: suitable for crushing medium hardness brittle rocks (ultimate compressive strength below 100MPa), as well as medium and low hard materials such as coal, limestone, etc. It has the characteristics of simple structure, high efficiency and high yield. It is widely used in mining, cement, coal, metallurgy, building materials, road construction, petroleum and chemical industries.

5. Roller crusher: suitable for crushing medium hardness tough rocks (ultimate compressive strength around 70MPa). It is also suitable for medium and fine crushing of medium hardness materials such as limestone, slag, coke, coal, etc. in cement, chemical, electric power, metallurgy and other industrial sectors.

Impact Crusher

6. Impact crusher: suitable for crushing medium hardness and soft materials (limestone, coal gangue, etc.). Use impact to crush materials, and repeatedly impact between the plate hammer and the impact plate to crush. New structural design, strong machine rigidity, large moment of inertia of the rotor, cubic shape of the finished product, no tension and cracks, good particle shape, high comprehensive benefits.

7. Impact crusher: also called sand making machine. Using the "stone hitting stone" crushing principle and technology, the material is crushed by the impact of the rapidly rotating moving parts. It has the advantages of simple structure, large crushing ratio, low energy consumption, high output, light weight, and the finished product after crushing is cubic.

It is widely used in various ore crushing, railways, highways, energy, cement, chemicals, construction and other industries.

8. Compound crusher: It is a new type of high-efficiency fine crushing equipment that integrates hammer crushing and impact crushing. It has outstanding advantages such as large production capacity, high crushing efficiency, large crushing ratio, small abrasion, low energy consumption, good sealing, stable operation and convenient maintenance. When building materials companies use this equipment to crush materials such as limestone, coal, coal gangue and cement clinker, it can significantly reduce the particle size entering the mill and increase the mill output. It is an ideal energy-saving crushing equipment.

9. Mobile crusher: It adopts self-driving mode and can be driven directly to the work site for multi-stage crushing. It also has the functions of feeding, screening, conveying, etc. Each component is fixed on an integral frame, and tires or crawlers are attached below to form a movable sand and gravel production line.

10. There are also various types of crushing equipment such as air-selected crusher, single-stage crusher, double-roll crusher, third-generation crusher (commonly known as new sand making machine).

PS: These equipments have their own characteristics and are suitable for different material properties and production needs. When choosing crushing equipment, it is necessary to comprehensively consider the specific crushing task, material properties, production requirements and economic factors.

Save Time! Get A Detailed Quotation Quickly.