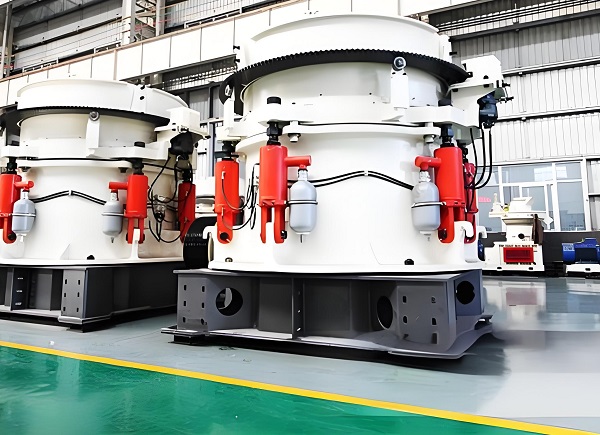

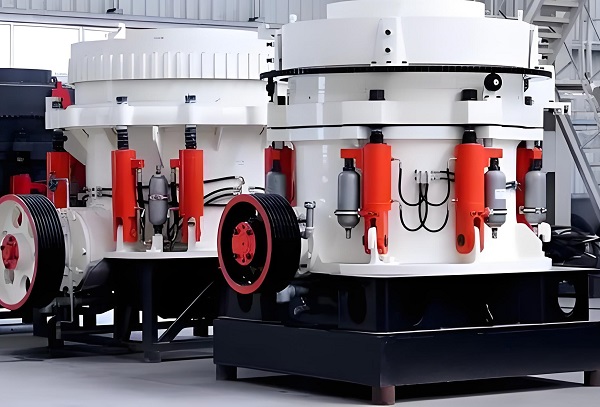

Crushing equipment is a core component of the large-scale production of sand and gravel aggregates and metal mining. Traditional equipment, limited by capacity, energy consumption, and operational shortcomings, struggles to adapt to the global mining industry's transformation toward larger-scale, intelligent, and greener production. Multi-cylinder cone crushers are adapting to this trend, addressing industry pain points through structural innovation, intelligent capabilities, and environmental upgrades. Their technological evolution not only improves crushing efficiency but also reshapes production costs and environmental considerations, making them a key piece of equipment for high-quality development in the mining industry.

In the large-scale production of sand and gravel aggregates and metal mining, multi-cylinder cone crushers, thanks to their efficient crushing performance, have become core equipment. As the global mining industry shifts toward larger-scale, intelligent, and green production, traditional equipment faces challenges such as insufficient capacity, high energy consumption, and complex operational maintenance. Multi-cylinder cone crushers are currently experiencing significant development through structural innovation, intelligent capabilities, and environmental upgrades. Their technological evolution not only boosts crushing efficiency but also reshapes the cost and environmental considerations of mining production, becoming a key support for the industry's high-quality development.

Current State of Technology: Triple Breakthroughs in Structure, Intelligence, and Environmental Protection

1. Structural Optimization: Laying a Solid Foundation for Efficient Crushing

Modern multi-cylinder cone crushers, with laminated crushing technology at their core, have achieved multi-dimensional structural upgrades. The MC300 model significantly enhances cone stability by increasing the diameter, eccentricity, and feed port size of the moving cone, combined with a fixed main shaft and anti-sway mechanism. This significantly increases the crushing capacity by over 30% compared to traditional spring cone crushers. Key component materials and processes are continuously upgraded. The main shaft and drive shaft are generally made of high-strength alloys. After a "medium-frequency quenching + low-temperature tempering" process, the hardness reaches HRC 55-60 while maintaining excellent toughness and extending component life by 50%.

Strengthening the frame structure is a common innovation. The upper section features a reinforced flange and ribbed plate, and the lower section is 50% thicker, increasing the equipment's power carrying capacity by 20%. As a global leader in large-scale crushing equipment, this model leverages nearly a century of technological expertise to optimize the crushing chamber, achieving "intergranular lamination crushing." The resulting finished product is polyhedral, with a needle-like content of less than 10%, making it a standard feature of domestic "super stone mines." Furthermore, the increasing adoption of modular design allows for quick replacement of vulnerable parts such as liners, reducing the replacement time for a single component set to less than two hours, significantly reducing maintenance costs.

2. Intelligent Control: Reshaping Equipment Operation Logic

Automation and intelligent technologies are deeply integrated into the entire equipment operation process. The multi-cylinder hydraulic cone crusher is equipped with a fully automated intelligent control system that monitors 12 key parameters, including crushing chamber load, oil temperature, and vibration, in real time. Using adaptive algorithms, it adjusts feed rate and discharge opening size to ensure a balance between production capacity and stability. More advanced intelligent systems have enabled "predictive maintenance." The smart mining ecosystem, integrating industrial big data and equipment diagnostics, can provide 72-hour advance warning of faults such as bearing wear and hydraulic system leaks, reducing unplanned downtime by 60%.

Remote operation and maintenance and cluster management are becoming increasingly popular. Global connectivity enabled by the Industrial Internet platform allows engineers to remotely adjust parameters and troubleshoot faults, resulting in an average equipment lifespan exceeding 20,000 hours. Domestic companies are exploring multi-device collaborative control, linking multiple cone crushers and screening equipment through a DCS system to dynamically match production line capacity, improving overall efficiency by 15%-20%.

3. Environmental Protection and Adaptability: Responding to Diverse Scenario Needs

Dust and noise reduction technologies achieve standardized configurations. Mainstream models generally utilize a Type I sealed dustproof design, coupled with a pulse dust collector interface, to keep dust emissions below 10mg/m³, well below the national limit of 30mg/m³. Vibration and noise control have been significantly improved. Through optimized composite rubber damping springs and rod buffer structures, operating noise has been reduced to under 85dB, a 15dB reduction compared to traditional equipment.

Continuously improving scenario adaptability, we have established a "universal + customized" product portfolio. For primary crushing in mining applications, the soon-to-be-released 1250 multi-cylinder cone crusher boasts an hourly output of over 2,000 tons, making it suitable for large-scale aggregate projects. For small and medium-sized production lines, models like the MC300, with an installed power of 250 kW, deliver efficient crushing, balancing production capacity and energy consumption. Furthermore, the equipment can customize the liner material based on material characteristics, such as wear-resistant ceramic liners for high-hardness ores and stainless steel liners for corrosive materials, further expanding its application potential.

Technological Development Trends: Large-Scale, Green, and Collaborative Development

1. Large-Scale and Ultra-Large-Scale: Adapting to Large-Scale Production

Global mining consolidation is driving demand for ultra-large equipment, accelerating the evolution of multi-cylinder cone crushers toward high-capacity, large-scale designs. Domestic companies have achieved significant breakthroughs. The 1250 model is expected to exceed 2,000 tons per hour, making it the largest multi-cylinder cone crusher in China. Among international brands, the HP series, by increasing the crushing chamber volume and motor power, has a single-unit processing capacity exceeding 1,800 tons per hour, making it suitable for aggregate production lines with an annual output of tens of millions of tons. Large-scale production not only increases production capacity but also reduces production line floor space by reducing the number of units, potentially lowering investment costs per unit of production capacity by 10%-15%.

2. Green and Low-Carbon: Reconstructing Energy Consumption and Environmental Standards

Energy-saving technology will shift from "single-point optimization" to "system integration." Future equipment will incorporate new permanent magnet synchronous motors, which reduce energy consumption by over 25% compared to traditional motors. Intelligent load regulation will also achieve a dynamic balance of "low consumption under light loads and high efficiency under heavy loads." Environmentally friendly design will be upgraded to "zero waste throughout the entire process." In addition to enhanced dust and noise reduction, waste heat recovery systems will be integrated to use heat generated during the crushing process to preheat drying equipment, further reducing overall energy consumption within the production line. Adaptability to the circular economy continues to improve. For recycled resources like construction waste and tailings, specialized crushing chambers and wear-resistant materials will be developed to achieve "low-loss, high-recovery" crushing. For example, for recycled aggregate in concrete, optimized chamber design increases the aggregate recycling rate to over 95%, while keeping the stone dust content below 5%, meeting standards for recycled building materials.

3. Intelligent Collaboration: Integrating into the Smart Mining Ecosystem

Digital twin technology will enable full equipment lifecycle management. By building virtual equipment models, operating status can be mapped in real time, and aging trends can be predicted, shifting maintenance from "post-repair" to "pre-emptive intervention." The in-depth application of industrial internet platforms will break down equipment silos. Multi-cylinder cone crushers can interconnect data with mining, screening, and transportation processes. Intelligent algorithms can optimize production scheduling, increasing overall production line capacity by over 20%.

Human-machine collaboration models continue to evolve, with operating interfaces moving toward minimalist and visual design. AR glasses enable remote fault diagnosis and operational guidance, lowering the skill threshold. At the same time, the equipment will possess stronger autonomous decision-making capabilities, automatically adjusting crushing parameters based on changes in raw material composition, enabling flexible production characterized by "raw material adaptation and product customization."

Multi-cylinder cone crushers have evolved from traditional crushing equipment into core equipment that integrates high efficiency, intelligence, and environmental protection. Structural optimization lays the foundation for performance, intelligent control improves operational efficiency, and environmentally friendly design broadens application scenarios. In the future, driven by large-scale, green, and intelligent collaborative technologies, they will further adapt to the global mining industry's demand for scale, low carbon, and intelligent development. Through continuous R&D investment and the integration of industry, academia, and research, domestic companies are gradually making the leap from "following" to "leading," injecting strong impetus into the high-quality development of mining equipment.

Multi-cylinder cone crushers have completed their transformation from traditional equipment to efficient, intelligent, and environmentally friendly equipment. Structural optimization strengthens performance, intelligent control enhances operational efficiency, and environmental adaptation broadens application scenarios. In the future, they will further develop in the direction of large-scale, green, and intelligent collaboration, precisely meeting the mining industry's demand for scale and low carbon development. Domestic companies are making the leap from following to leading by leveraging technological innovation, providing core support for global mining equipment upgrades and high-quality development.

Save Time! Get A Detailed Quotation Quickly.