In modern industrial production processes, screening is crucial, directly impacting product quality and production efficiency. As a leading screening equipment brand, the Zhongcheng Swing Screen is highly favored by numerous industries for its unique features and significant advantages. Below, we'll delve into the advantages of the Zhongcheng Swing Screen.

Innovative Operating Principle Lays the Foundation for Efficiency

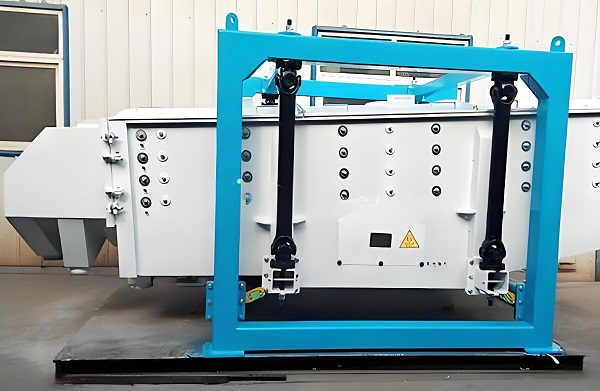

The Zhongcheng Swing Screen cleverly draws on the principles of manual screening. Driven by an eccentric shaft, it imparts a unique three-dimensional motion to the screen. The screen not only oscillates periodically horizontally but also exhibits an upward and downward oscillation at a specific angle. This innovative motion pattern creates a spiral path for the material on the screen surface. Compared to traditional screening equipment, the material's screening path on the Zhongcheng Swing Screen is significantly extended, providing more contact between the material and the screen, significantly improving screening accuracy and efficiency. For example, in the fine chemical industry, when processing nano-powder materials, conventional screening equipment struggles to accurately classify them. However, the Zhongcheng Swing Screen, with its unique motion path, can precisely separate powders of varying particle sizes, meeting the demands of high-end product production.

1. Fine Screening to Meet Stringent Particle Size Requirements

The Zhongcheng Oscillating Screen offers exceptional screening accuracy, thanks to its precise mesh configuration and rational structural design. The device can achieve particle size classification from 0.02mm to 300mm, particularly advantageous when processing ultrafine powders below 500 mesh, with a screening accuracy exceeding 95%. In the food industry, the coarseness and fineness of flour directly impacts the taste and quality of food. The Zhongcheng Oscillating Screen precisely controls flour particle size, ensuring uniform flour coarseness and a delicate, chewy texture for pasta. In the pharmaceutical field, the particle size of pharmaceutical granules or powders is crucial to their efficacy. The Zhongcheng Oscillating Screen's high-precision screening ensures uniform composition and stable efficacy, providing a solid guarantee for drug quality.

2. High Processing Capacity, Improved Production Efficiency

In actual production, processing capacity determines a company's efficiency and production capacity. The Zhongcheng Oscillating Screen provides a long and evenly distributed path for material on the screen surface, significantly increasing throughput per unit time. With comparable specifications, its processing capacity is 1.5 to 2 times that of ordinary vibrating screens. For example, in the mining industry, when processing large quantities of ore raw materials, the Zhongcheng Vibrating Screen can quickly separate ore of varying particle sizes. Its efficient screening capabilities enable production lines to maintain high production capacity, reduce material backlogs, and significantly improve the economic benefits of mining companies. In the plastics recycling industry, faced with large quantities of plastic pellets or fragments awaiting recycling, the Zhongcheng Vibrating Screen can also quickly complete screening, providing sufficient raw materials for subsequent plastic processing and improving the overall production efficiency of recycling companies.

3. Energy-saving and low-consumption, in line with green production concepts

With rising energy costs and increasingly stringent environmental protection requirements, the energy-saving performance of equipment has become increasingly critical. Zhongcheng Vibrating Screens are fully considered energy-efficient during their design and manufacturing. They feature a low-power motor, low operating noise (≤75 decibels), and consume 40% less energy than traditional equipment. Their low-speed, large-swing design ensures efficient screening while reducing energy consumption. In chemical companies, large quantities of screening equipment are constantly in operation, resulting in high energy costs. The Zhongcheng Swing Screen's energy-saving features can effectively reduce production costs. Furthermore, its low-noise operation improves the workshop environment, aligning with the modern industrial philosophy of green, environmentally friendly, and comfortable production.

4. Wide Material Compatibility and Diverse Application Scenarios

Industrial production involves a wide variety of materials with varying properties. The Zhongcheng Swing Screen demonstrates strong material compatibility. Whether it's granular or powdery materials, or sticky (when paired with an anti-stick screen), or materials with low moisture content, it easily handles them and is remarkably resistant to screen clogging. In the feed industry, where materials contain complex ingredients, including grain pellets and powdered additives, the Zhongcheng Swing Screen effectively screens these mixtures to ensure uniform feed composition. In the building materials industry, when processing materials like sand, gravel, and cement, the Zhongcheng Swing Screen, with its excellent material compatibility and stable operation, provides reliable screening support for building materials production. It is widely used in raw material pretreatment, product grading, and other processes across multiple industries.

5. Convenient Maintenance, Reduces Operating Costs

The ease and cost of equipment maintenance directly impact a company's operational efficiency. Zhongcheng's swing screens are easy to replace, with some models supporting quick screen changes, significantly reducing maintenance time. Their compact structure minimizes wearing parts, with key components like the screen and bearings being inexpensive to replace and readily accessible. During daily operations, even if the screen becomes worn and requires replacement, operators can quickly complete the process, restoring the equipment. Compared to other screening equipment with complex maintenance and long maintenance cycles, Zhongcheng's swing screens effectively reduce equipment downtime, lowering maintenance costs and production losses, while improving overall stability and reliability.

6. Excellent Sealing for Environmental Protection and Hygiene

In industries with stringent hygiene requirements, such as food and pharmaceuticals, and dust-prone industries like chemicals, equipment sealing is crucial. Zhongcheng's swing screens feature a fully sealed design with a sealing cover and dust extraction port for connection to dust extraction equipment, effectively minimizing dust spillage and meeting environmental standards. Models specifically designed for the food industry are constructed from 304/316L stainless steel with a polished surface to meet GMP hygiene standards. When producing pharmaceuticals or food additives, it prevents the influx of foreign impurities and ensures product purity. In chemical production, it prevents the spread of harmful dust, protecting the workshop environment and operator health, achieving the dual goals of environmentally friendly and safe production.

7. Stable Operation and Long Equipment Life

The Zhongcheng Swing Screen features a small amplitude (1-3mm), resulting in minimal vibration during operation. It requires minimal foundation and can be installed on floors or mobile platforms, expanding installation flexibility. Key components such as the main shaft and bearings are made of high-strength materials, and precision machining ensures a service life of 5-8 years. It maintains stable operation even in long-term, high-intensity industrial production. In the metallurgical industry, where screening environments are harsh and workloads are intense, the Zhongcheng Swing Screen, with its stable performance and long service life, has withstood the test of harsh environments and high workloads. It continues to provide reliable screening services for metallurgical production, reducing the cost and time associated with frequent equipment replacement and repair.

8. Flexible Adjustability to Adapt to Different Production Needs

Different companies and production processes have varying requirements for screening equipment parameters. The Zhongcheng Swing Screen can easily adapt to different material screening requirements by adjusting parameters such as speed, inclination, and amplitude. If material characteristics change during the production process, such as moisture or particle shape, the operator can adjust equipment parameters promptly to ensure screening results are not affected. Furthermore, the equipment supports integration with the production line and is equipped with a PLC control system, enabling automated feeding, screening, and unloading, reducing labor costs. In the highly automated electronics manufacturing industry, the Zhongcheng Swing Screen can be seamlessly integrated into the production line, precisely controlling the screening process according to the production rhythm, improving production automation and overall efficiency.

With its innovative operating principle, high-precision screening, large processing capacity, energy-saving and low consumption, wide material compatibility, easy maintenance, excellent sealing, stable operation, and flexible adjustability, the Zhongcheng Swing Screen is an ideal choice for screening operations across various industries. Whether in the food and pharmaceutical industries that pursue high-quality products, or in industries such as chemicals and mining that prioritize production efficiency and cost control, the Zhongcheng Swing Screen provides efficient and reliable screening solutions, helping companies improve production efficiency and stand out in the fiercely competitive market.

Save Time! Get A Detailed Quotation Quickly.